Today's bumping processes create features in a wide variety of shapes, densities, quantities and materials. Collectively, they create the connections that drive device functionality, quality and yield.

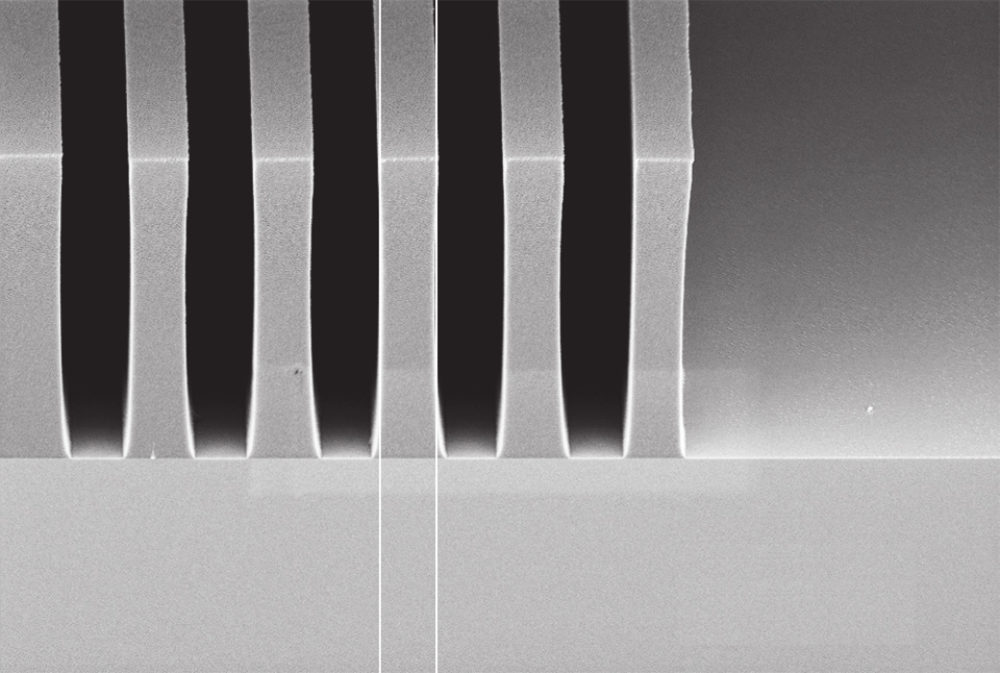

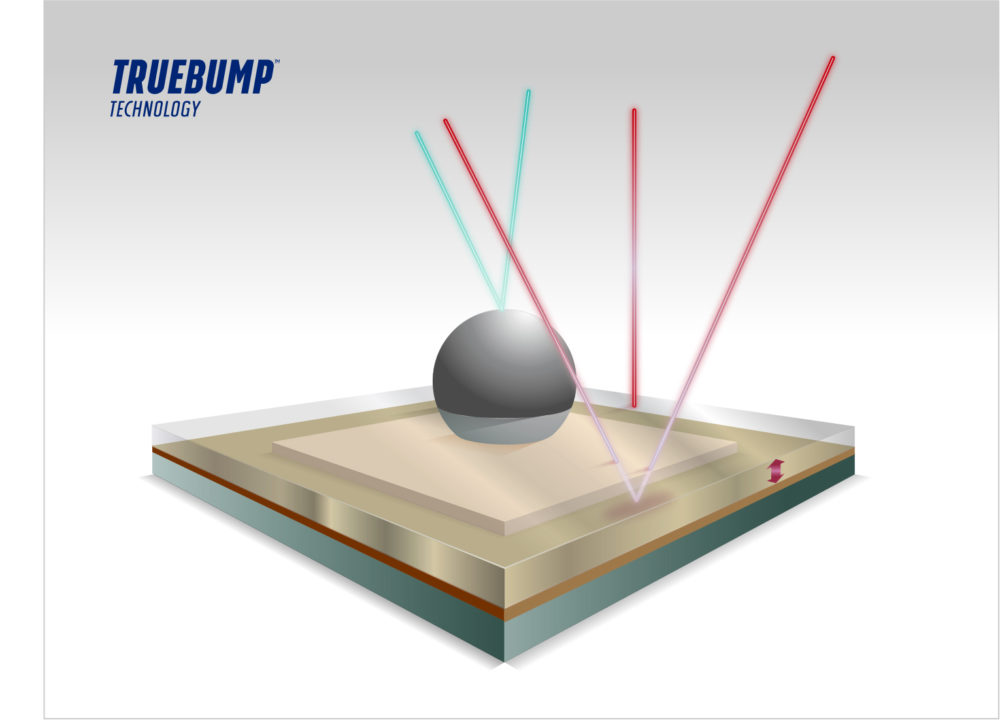

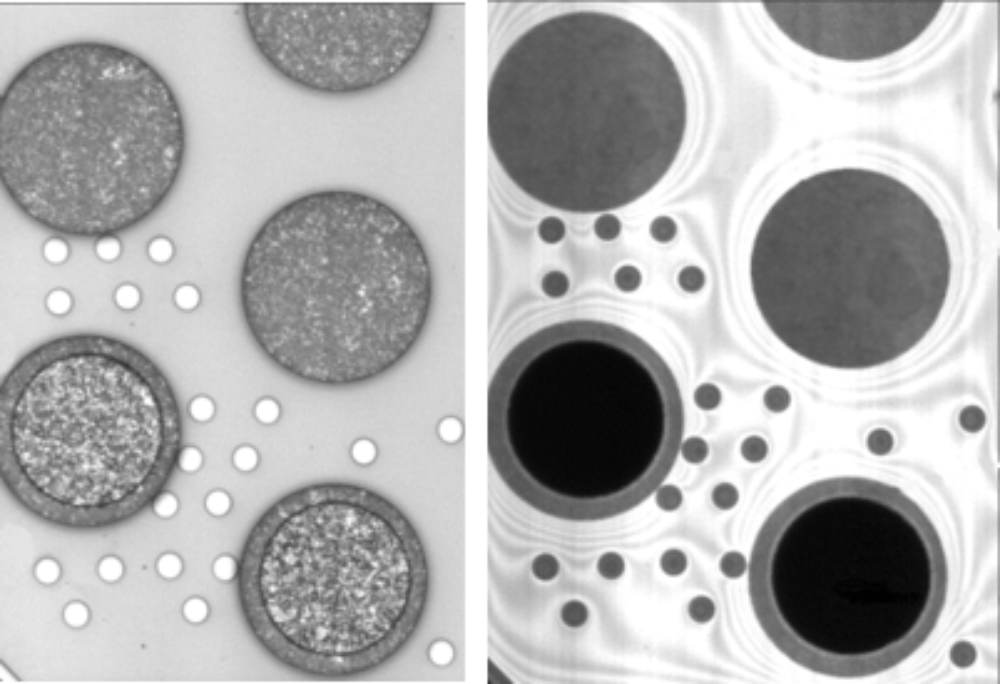

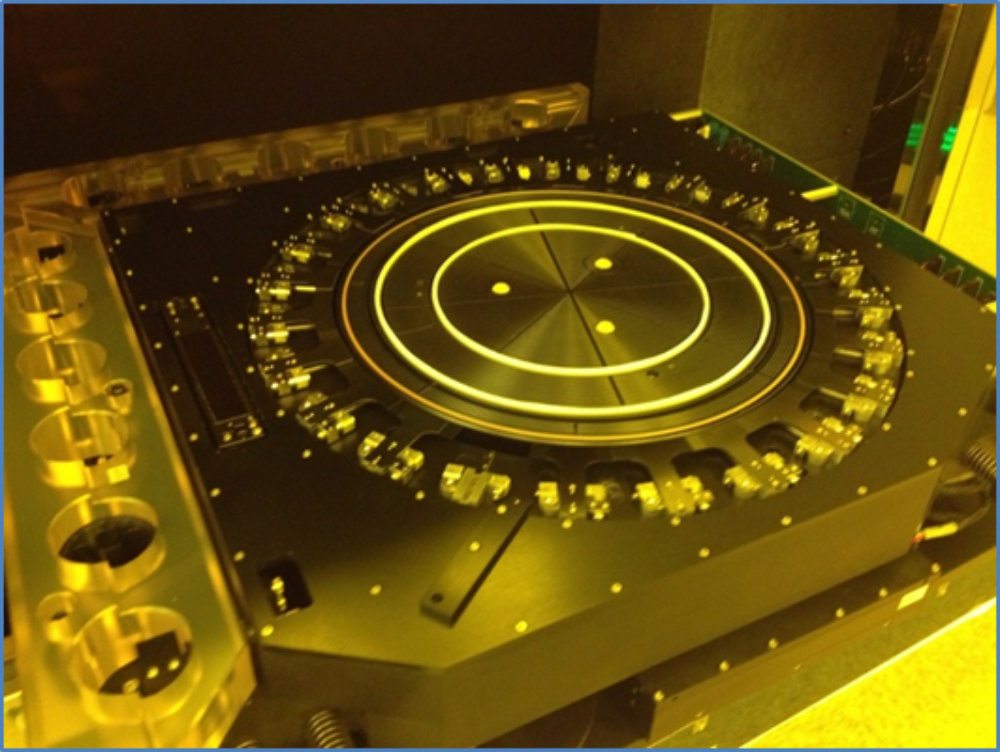

Cu pillar and microbump processes are trending toward smaller features to enable tighter integration and more functionality. The inspection and metrology required to ensure process control needs to have the resolution and accuracy to provide meaningful results that are well within the process tolerance window. Accuracy of the measurement drives all results including die-based coplanarity, average bump heights, individual bump heights and all subsequent analysis. Onto Innovation's Truebump Technology leverages multiple technologies to help ensure that thin films present on the wafer do not falsely increase or decrease the resulting bump heights being reported.

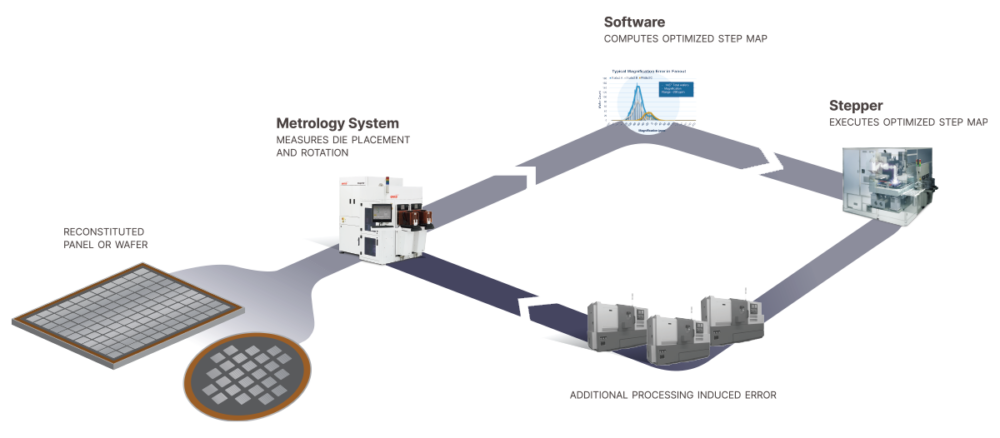

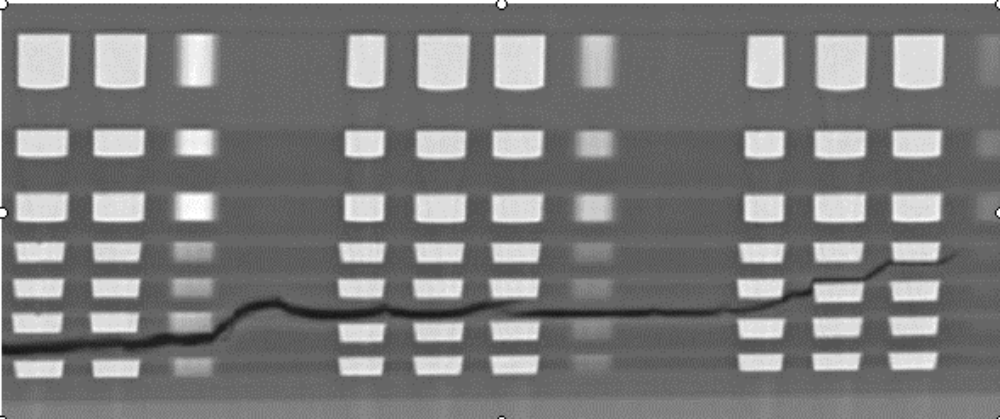

Redistribution layers and under bump metallization for smaller bumps with tighter process windows increase the complexity of the process and drive the need for more front-end like automated and sophisticated metrology systems in back-end packaging. Onto Innovation provides solutions for integrated interferometric structure step-height metrology as well as options for on-product film-stack metrology using acoustic wave technology. These 3D measurements can be augmented with high resolution 2D metrology and inspection of the same features to help ensure that RDL is meeting requirements based on design rules and that there are no process excursions leading to electrical failures.

A single wafer will go through multiple process steps in the bumping process, generating layers of defect and metrology data that can be a powerful tool when handled correctly and efficiently. Onto Innovation's yield management software gives users the analytical tools to visualize data, correct process variation, and improve yield by easily analyzing multi-layer, multi-wafer and multi-lot results that include defect, 2D and 3D metrology data all in a single database with a single user interface.