Echo™ System

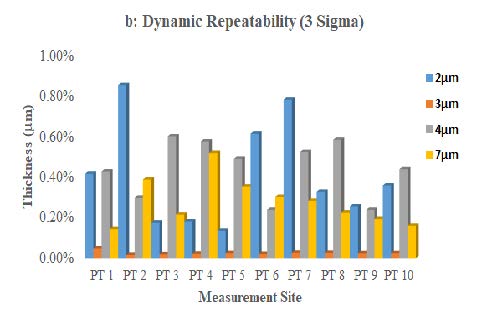

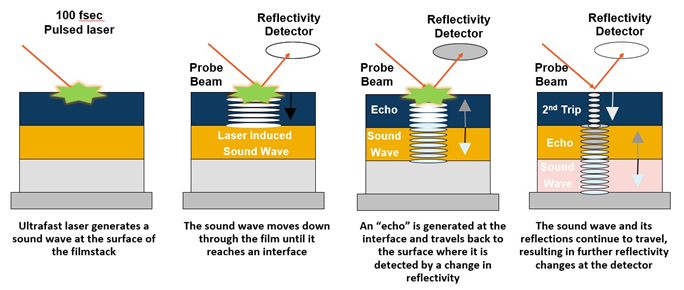

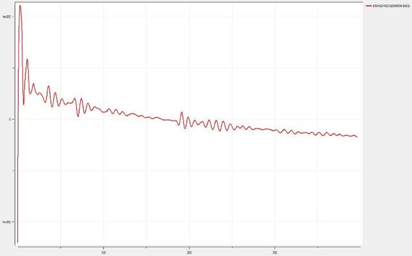

The Echo system utilizes picosecond ultrasonics to provide accurate, in-line, on-product metrology and materials characterization for semiconductor processes requiring metal thickness metrology, implant monitoring or thermal conductivity characterization on product wafers.

Product Overview

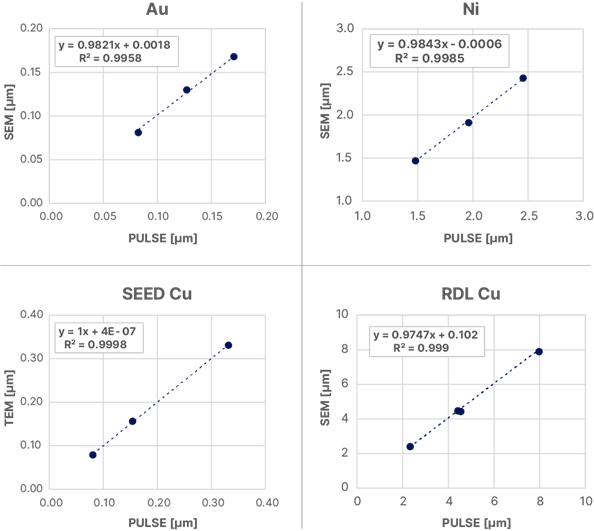

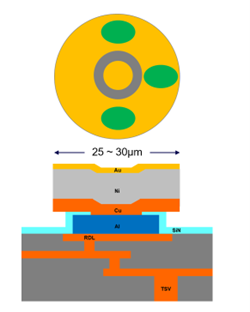

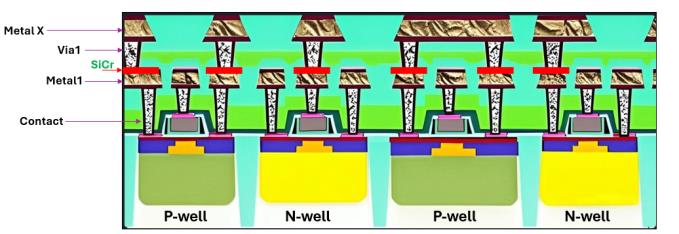

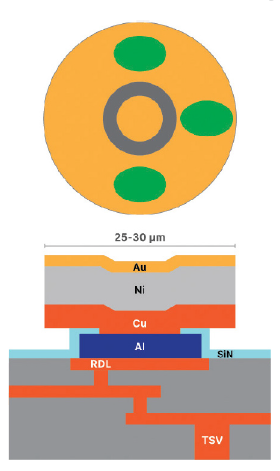

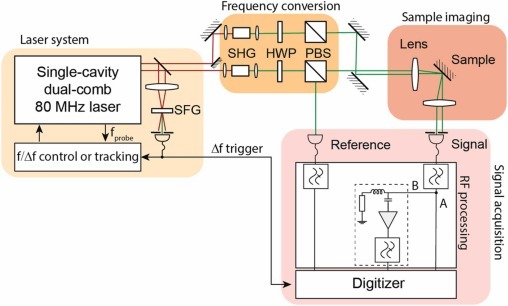

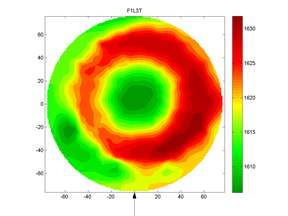

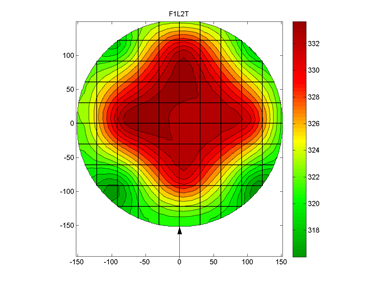

The Echo system is a comprehensive in-line metal film metrology tool designed for single and multi-layer metal film measurements in leading-edge logic, memory, advanced packaging and specialty semiconductor devices. Its innovative optics design extends the dynamic range for film thickness measurement from 50Å to 35µm on a single platform and offers extendibility to measure high aspect ratio advanced 3D NAND structures. The Expert Applications System (EASy™) software provides flexibility for developing user-defined algorithms to model complex multi-layer stacks.

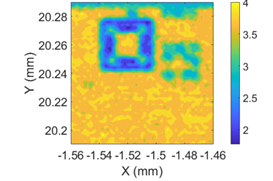

The Echo system’s capabilities have been extended to include materials characterization. In addition to measuring the Young’s Modulus of low-k dielectric films in BEOL and amorphous carbon hard masks in 3D NAND, the Echo system includes proprietary electronics and algorithms for implant monitoring and thermal conductivity characterization. Its small spot size, combined with rapid measurements, enables full wafer mapping capabilities with 0.5mm edge exclusion, improving time to yield.

Applications

- Gate metals, plug/contact, barrier/seed layers, top metal

- RF electrode/IDT

- Advanced packaging UBM, RDL

- 3D NAND Hard mask

- MEMS Poly/Ge

- Low-k, ultra low-k film modulus, implant, thermal conductivity

Do you have an Echo system question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields