Inspection Tool Productivity Software

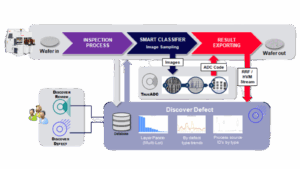

The native integration of the Discover software platform boosts tool throughput and enhances inspection quality by capturing more defects of interest. It provides a complete reduced review solution utilizing advanced machine learning (ML) and artificial intelligence (AI) technologies, customized to meet unique customer needs.

Enhance Your Inspection & Metrology Experience with Onto Software

Optimized Image Capture for Inspection Tools

Discover software enhances inspection quality and tool throughput by optimizing the image capture sample plan.

AI-Powered Automatic Defect Classification (TrueADC Software)

Integrated AI-based classification improves device quality and yield, driving fab efficiency and productivity.

Streamlined Review Software

Reduced review best practices improve operator productivity, enhance engineering review quality, and shorten review time.

Advanced Defect Analytics

Comprehensive inline wafer/panel monitoring enables automatic alarm notifications, detailed reports and Out-of-Control Action Plans (OCAPs).

Defect Source Analysis

Enables actionable process feedback to improve manufacturing outcomes.

Automated Business Analysis with Report Server

Boosts engineering productivity by up to 25% and supports multiple production report formats.

Machine Learning-Based Pattern Detection

The Discover Patterns software module proactively identifies wafer-level systematic yield-limiting issues and classifies them for analytics, enabling both process feedback and feedforward.

Centralized Defect & Metrology Management

Built on a scalable Big Data and high-availability architecture, this solution supports advanced applications such as high volume manufacturing (HVM) bump metrology, capable of handling wafers with over 100 million bumps.

Do you have an Inspection Tool Productivity Software question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields