Blog Post posted on Mar 20, 2019

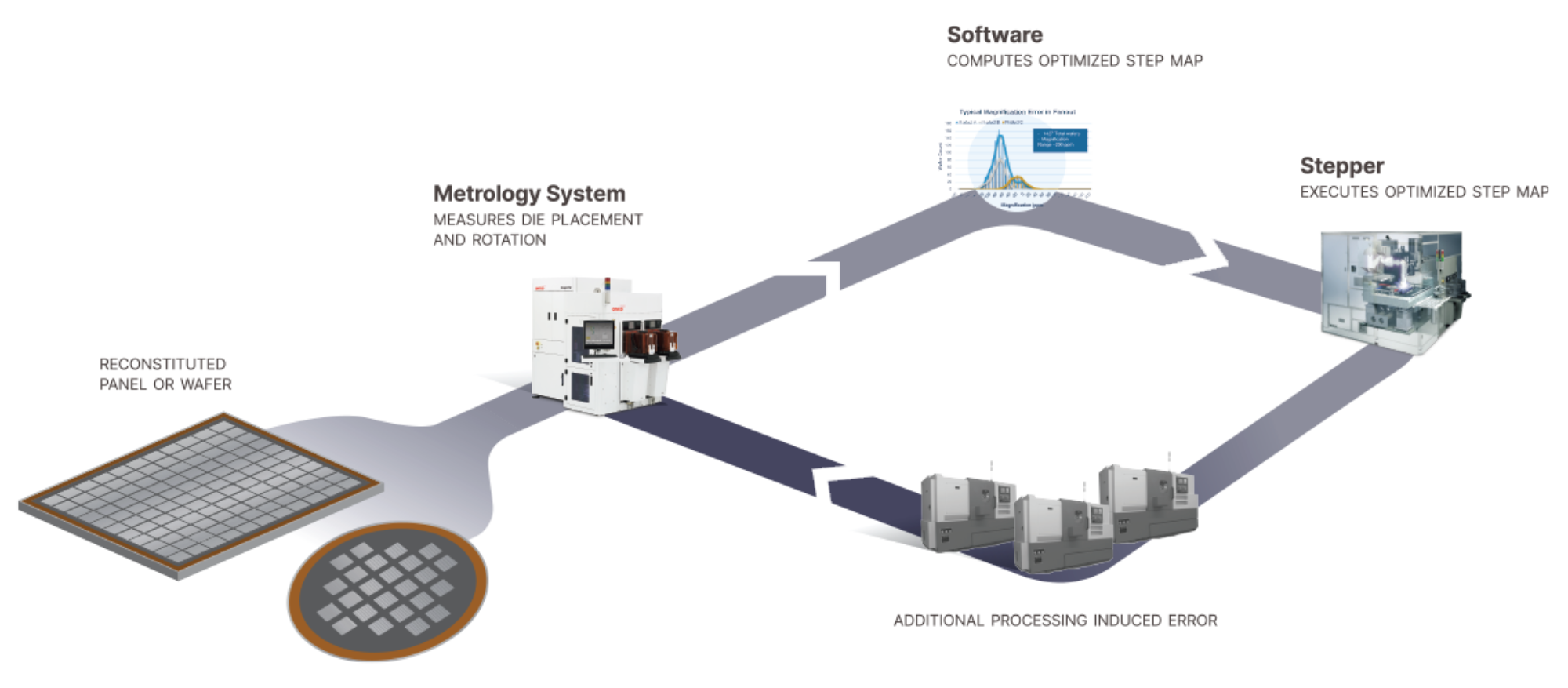

While fan-out packaging has many advantages, it also faces significant challenges. Die placement errors on reconstituted wafer or panel substrates can have a large impact on productivity and yield. The pick and place process itself introduces initial error. Additional error is created in the mold process and by instability of the mold compound through repeated processing cycles. As a result, the position of the die must be measured before each exposure in the lithography system to ensure sufficient registration with the underlying layer.

The Onto Innovation StepFAST® Solution is a feed-forward adaptive shot technology that addresses process variations, die placement errors and dimensionally unstable materials. The solution uses a parallel die placement measurement process and advanced analytics to provide a means to balance productivity against yield. Displacement errors can be measured on the lithography tool, but the measurements are slow, typically taking as much time as the exposure. Moving the measurements to a separate system (Firefly system) and feeding corrections to the JetStep system can double throughput. Discover software adds predictive yield analysis to the external measurement and correction procedures and increases the number of die included in the exposure field up to a user-specified yield threshold.

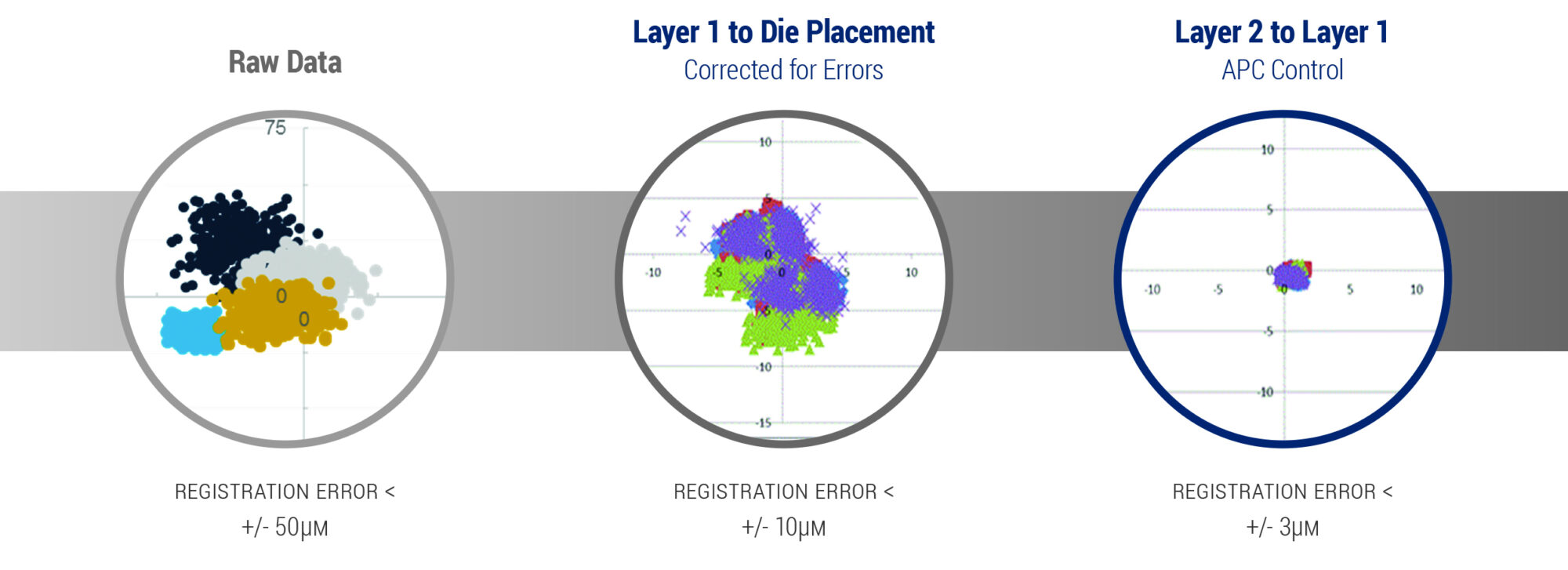

Measurement and analysis are repeated after each layer is exposed, calculating a new set of corrections, improving yield. Raw data registration errors are quickly corrected, and APC run-to-run control corrections further improve registration from +/-50µm to less than +/-3µm.

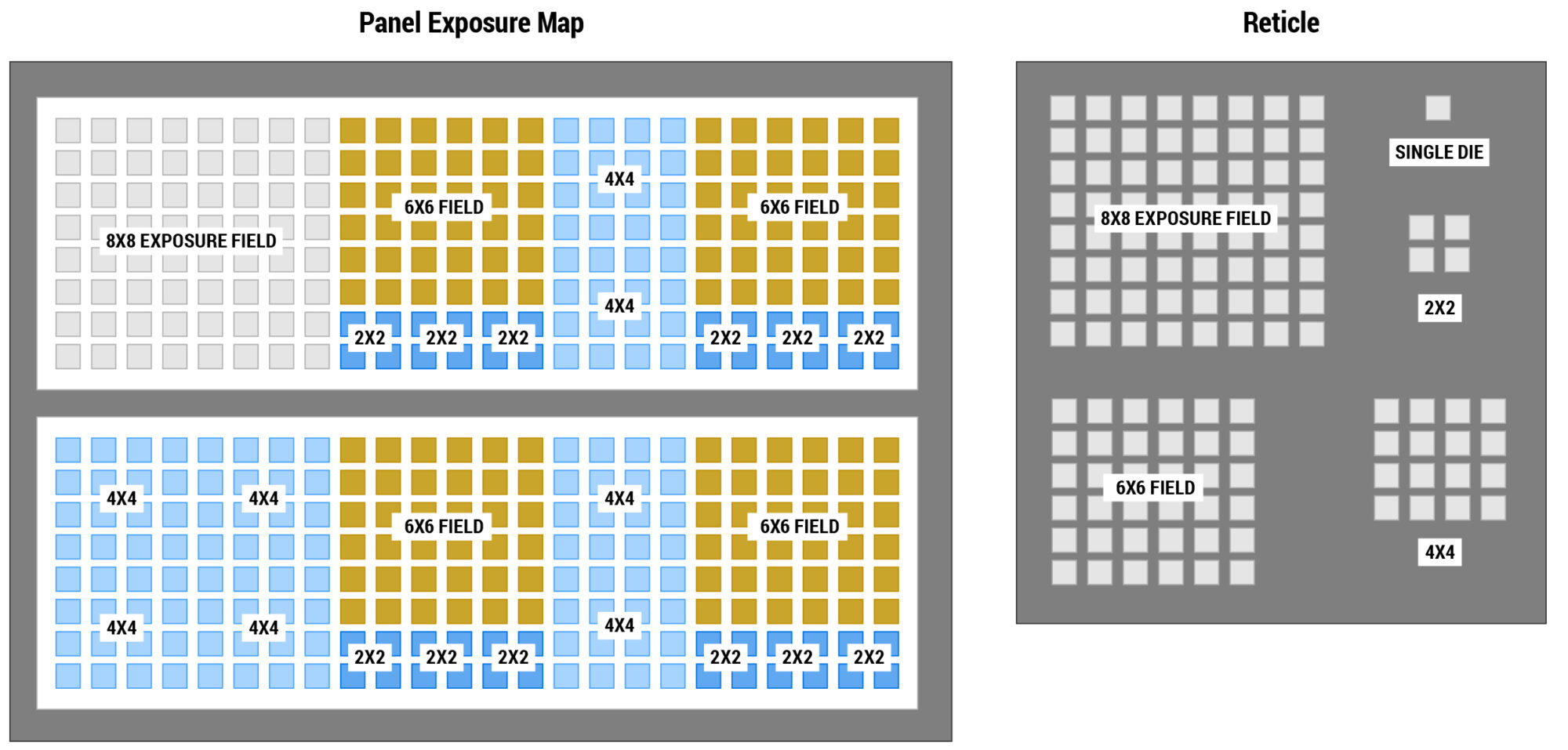

The StepFAST Solution adds predictive yield analysis to the external measurement and correction procedures and increases the number of die included in the exposure field up to a user-specified yield threshold. Under software control, a reticle containing multiple field sizes directs the stepper to expose fields as required to cover the panel while balancing throughput (field size) and yield (overlay error).

Onto Innovation's StepFAST Solution can increase lithography throughput by more than an order of magnitude and deliver commensurate reductions in cost of ownership. The method also provides a means to balance productivity (throughput) against yield, adding an extra dimension of flexibility for optimizing profitability.