Cloud

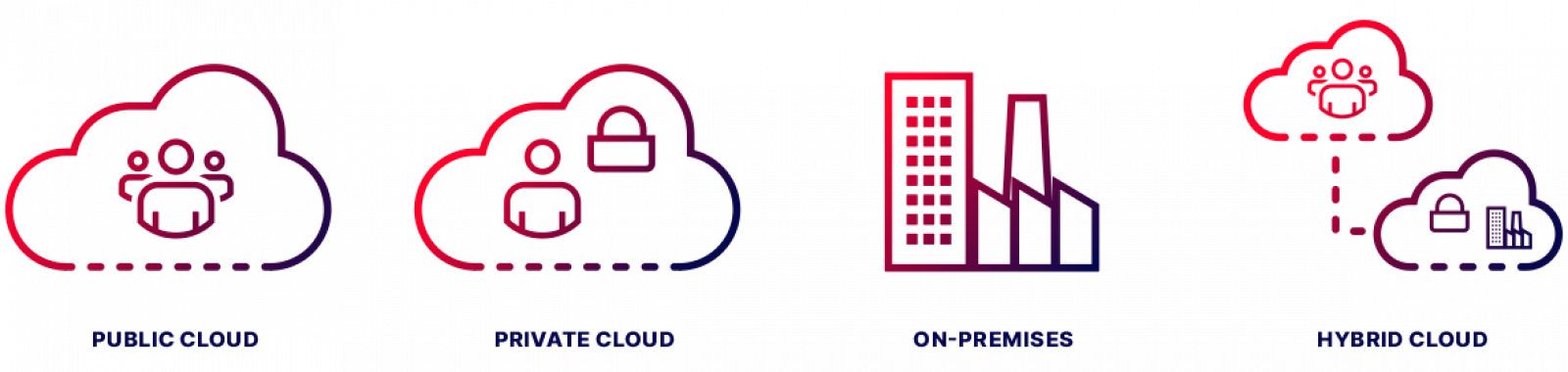

Onto software solutions are designed to run anywhere from mission critical systems for factory operation to the near-time analytics used by engineers in daily problem solving. While not all our products are best suited to cloud deployment, Onto Innovation supports our customers by meeting their needs for on premises deployment, cloud deployment, or a mixed configuration of the two.

Onto Innovation products have already been successfully deployed to AWS (Amazon Web Services), Microsoft Azure, and in hybrid mode. We are open to exploring which solution works best for you.

Chip Security

Regardless of where an Onto Innovation solution is deployed, we take the protection of our customer’s information very seriously to ensure that our security framework will meet your requirements.

Our on-premises deployment is secured within a customer’s firewall. No data leaves the internal IT environment. Onto client interfaces are all password protected completely without the customer’s control. Data within our repositories is secured by table and row level configurations that each customer can implement as needed.

Our cloud solutions are hosted by a dedicated Virtual Private Cloud. Each customer receives their own space with no sharing of data or applications. Much like an on-premises installation, the entire solution will be protected with VPN access. The mutually agreed upon cloud service provides security compliances and audit capabilities.

Customer data shared with Onto is protected by NDA agreement. Once data is received through an sFTP portal, it is protected by Onto’s firewall and VPN access. Only authorized application and integration engineers are granted access to the data.

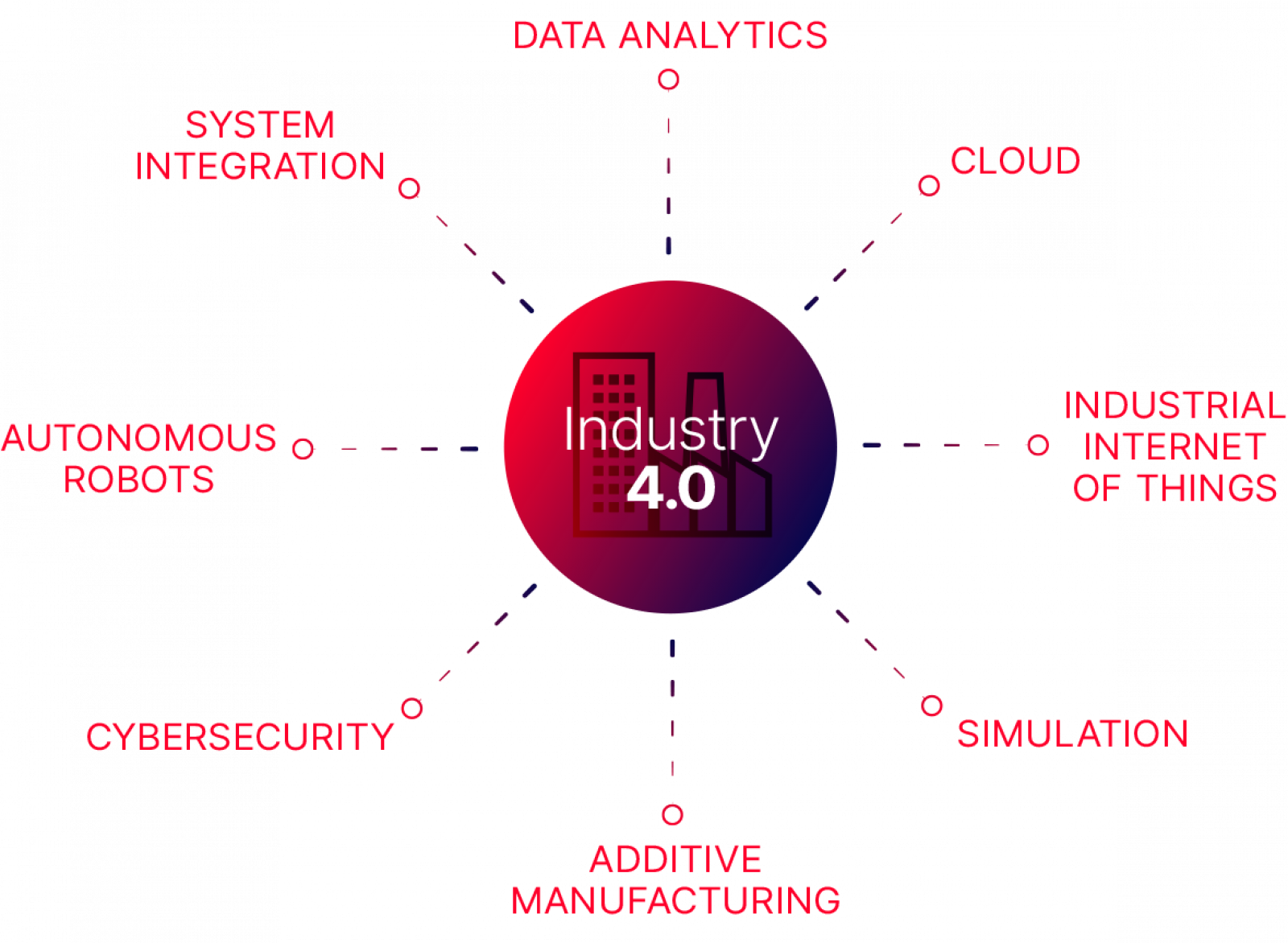

Industry 4.0

Industry 4.0 requires high-speed, integrated data designs like the ones built by the Onto Innovation software team to capture the multitude of signals coming off tool sensors. Last year alone, Onto Innovation software processed roughly 16 pedibytes (1600 terrabytes) of data.

Our software is built to integrate and adapt to existing smart factory frameworks throughout the digital transformation process:

- Discover FDC: System and tool control, fleet management (IOT, Autonomous Robots)

- Discover Run-to-Run: Ability to simulate disruption and the impacts before they occur (SI, Simulation)

- Discover Yield: Toolbox to analyze entire supply chain (Cybersecurity, Additive Manufacturing, SI, Data Analytics, Cloud, Simulation)

- Discover Defect: Empowers operators with factory visibility. (Data and Analytics, Additive Manufacturing)

- AutoShell: Delivering the tools to the network (SI, Autonomous Robots, IOT)

- Yield Optimizer: Exposing the knobs fit to turn (Data analytics, Simulation, and Additive Manufacturing)

- Discover Patterns: Consistent Classification 24/7 365 (Autonomous Robots)

- TrueADC: Consistent Classification 24/7 365 (Autonomous Robots)

Artificial Intelligence (AI)

Machine learning & AI algorithms are leveraged throughout our portfolio to amalgamate & normalize data for a line, a fab, or across the entire manufacturing enterprise.

Onto’s AI-enabled software suite is the perfect fusion of our rich domain knowledge and the latest artificial intelligence. Rather than intervening in factory processes, our machine learning approaches utilize AI’s predictive ability to tackle difficult problems or when a human expert is not available to categorize data. When it’s simply not cost effective to employ experts, artificial intelligence provides an additional perspective to ensure that changes are validated from multiple points of view before being introduced into manufacturing.

Environmental, Social, and Corporate Governance

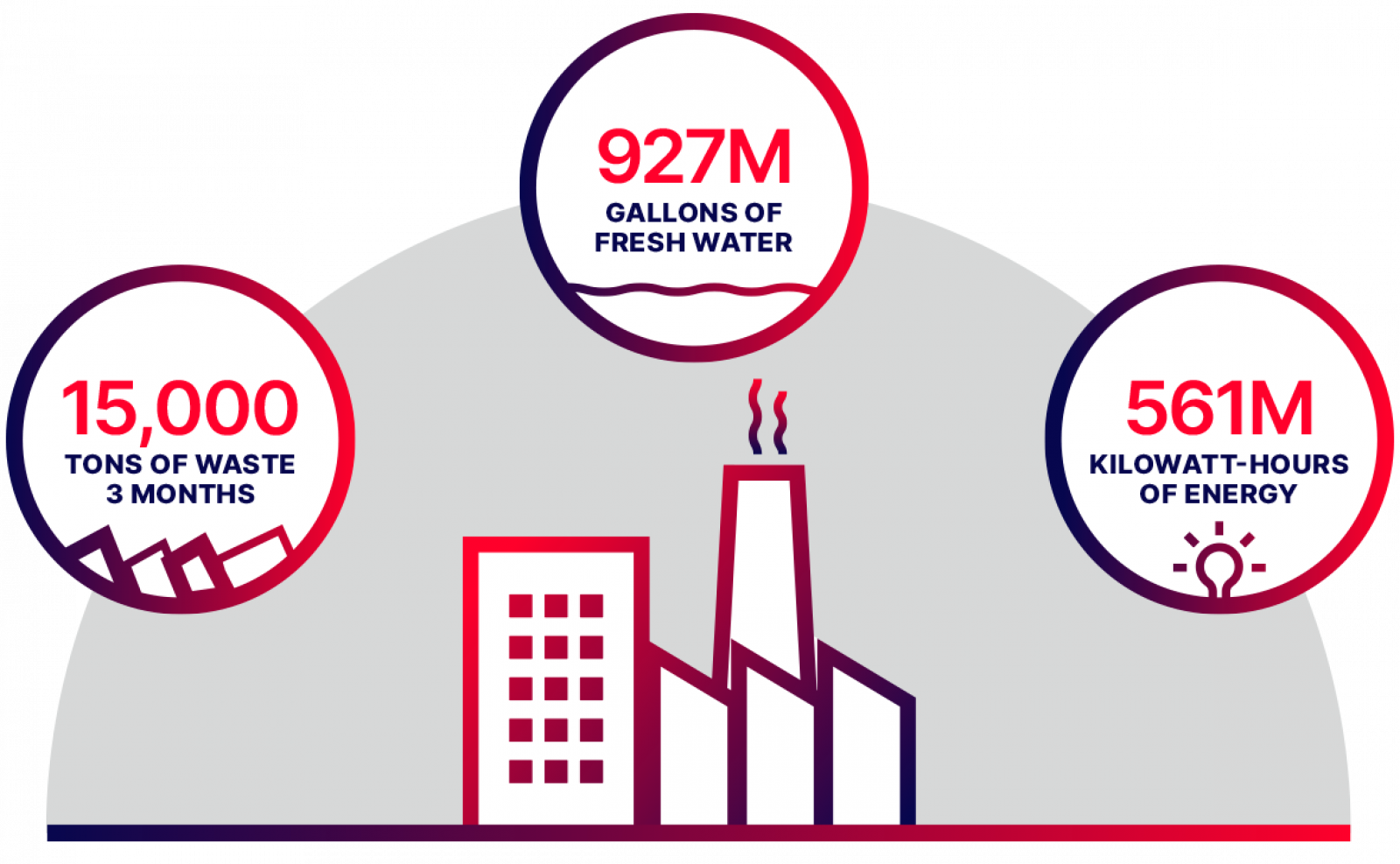

The positive effects of a concise, efficient factory process extend beyond the bottom line. By its very nature, yield improvement is green! While the majority of Onto Innovation software customers gain greater than 1% yield savings within the first year of deployment, a yield improvement of even 1% reduces a factory’s carbon footprint with staggering annual environmental savings, including but not limited to:

- 450 tons of waste (270 toxic tons)*

- 37 million gallons a year of fresh water*

- 22.5 million kilowatt-hours of energy*

To see all the steps Onto Innovation as a company has taken in its efforts to promote sustainability and have a positive influence on the communities in which we reside, see the Corporate Social Responsibility Report.

*Estimates based on statistics published by The Guardian.