Product Overview

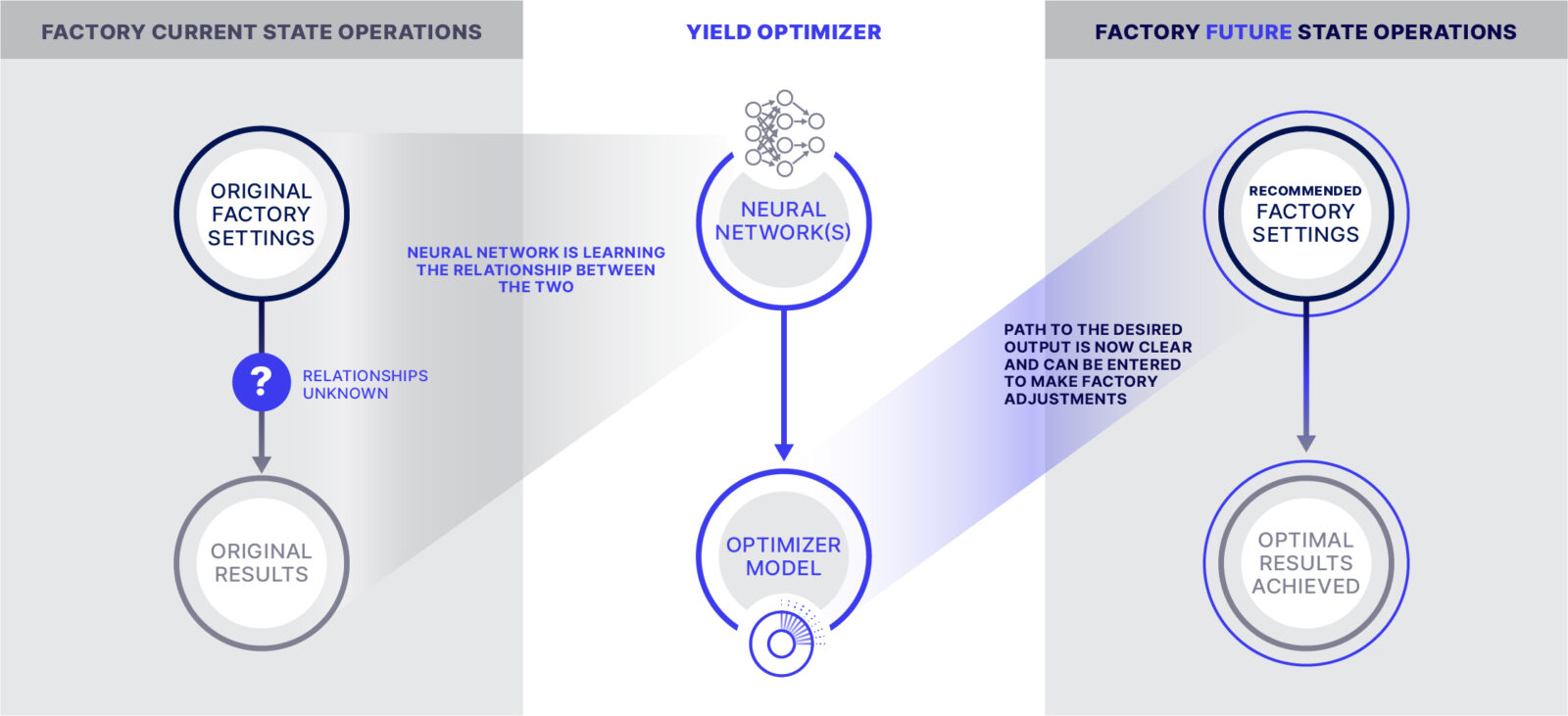

Yield Optimizer software is the next incarnation of analytics on the evolutionary scale. The software’s disruptive technology looks at relationships between multivariant data and their complex interactions. Taking any set of conceivable inputs and outputs, Yield Optimizer software identifies the relationships and interactions that lead to positive operational changes. Easily understood visuals empower even casual users to understand what is important before making adjustments.

Yield Optimizer software evaluates multiple models and suggests the best one for the data. Using machine learning, it examines the interactions between in-process metrology readings and end-of-line test results for any semiconductor product family and recommends changes to the in-process metrology targets. When licensed as a service, it enables users to leverage an on-demand infrastructure to apply easily understood workflows for complex analytics without the overhead.

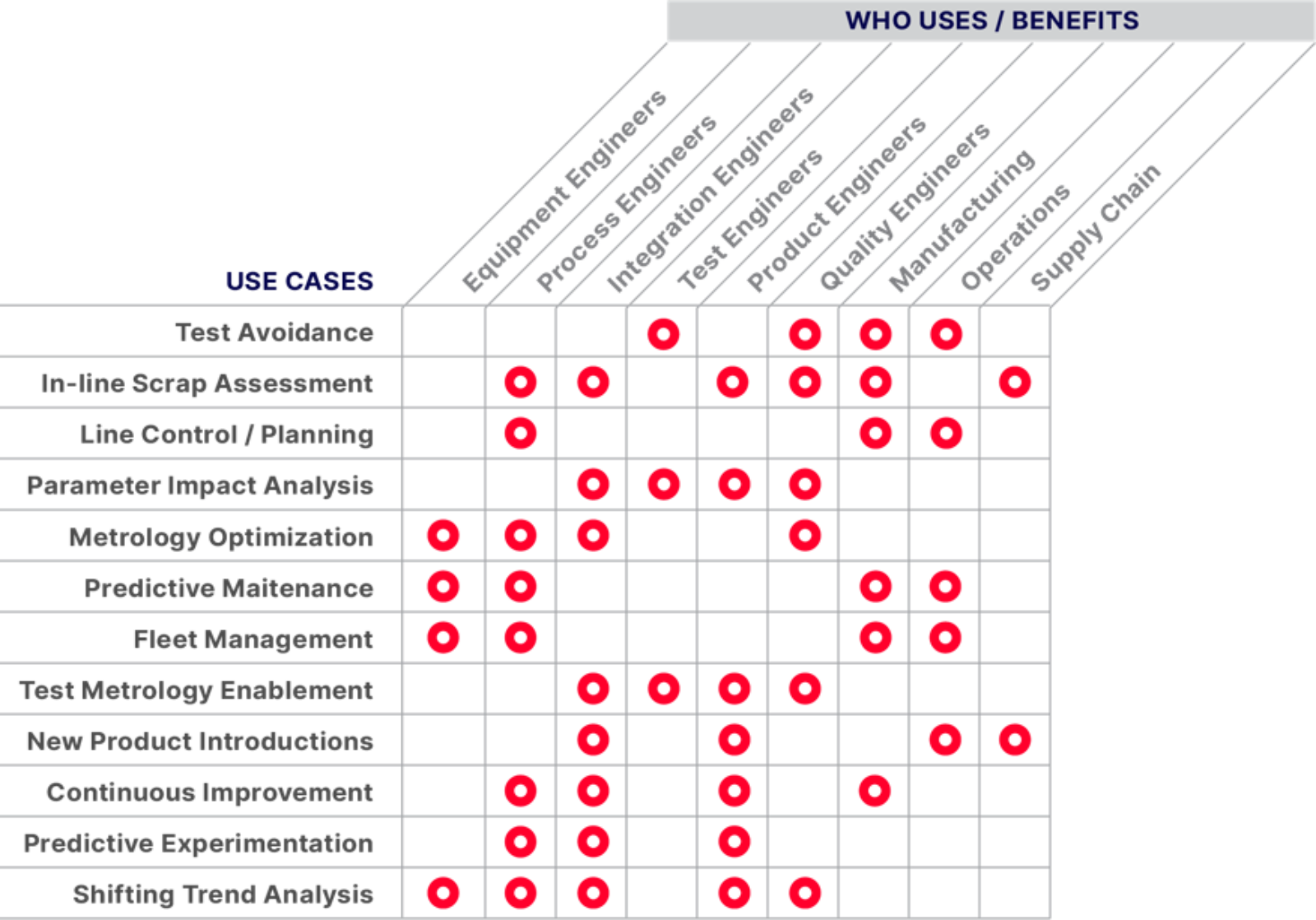

Analytic Applications

Yield Prediction – Forecast downstream yield or other performance parameters; for individual die, package parts or assembled modules based on current and upstream inputs.

Metrology Prediction – Forecast downstream metrology results based on upstream equipment data (such as FDC).

Process Corners Outlier Identification – Identify new or previously uncharacterized corners in operations or materials being generated by a factory.

Process Targeting – Determine the optimal conditions for favorable yield or performance results providing updated set-points to implement changes

Design of Experiment (DOE) Assistant – Apply the neural network models to predict the impact of planned process changes due to experimentation. This is especially effective in complex cause and effect models.

Troubleshooting - Apply results of Yield Optimizer software models in troubleshooting mode, even when data is incomplete.