Product Overview

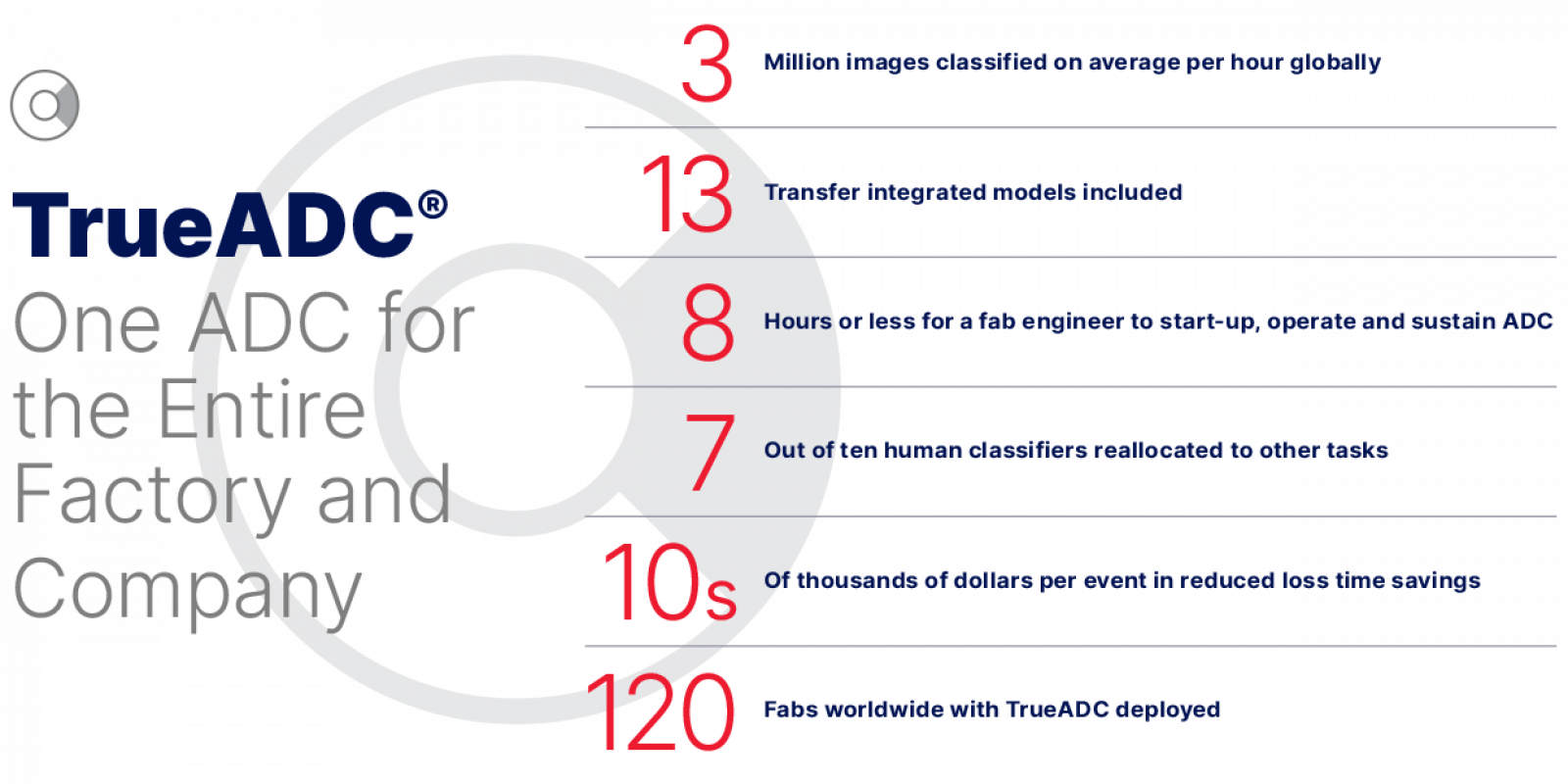

With deployable classifiers in as little as eight hours and high-speed classification rates over 180 defects per minute, TrueADC is the one Automated Defect Classification system for your entire Industry 4.0 enterprise. TrueADC’s one agnostic platform accepts results from all defect scan and optical review systems, including SEM. Featuring smart factory-style automation extendable across an entire supply chain, TrueADC is the only automated defect classification solution you need.

Choose the best implementation. TrueADC can perform classic SPC enhanced defect Paretos or deliver a definitive quality assessment of each die based on every defect, killer or non-killer. What are your goals? Defect Paretos allows engineers to quickly drive toward root causes based on specifically identified types of defects. As a definitive outgoing quality assessment (OQA) tool, TrueADC classifies a die based on its specific defects - effectively reducing the opportunity for escapes and overkill.

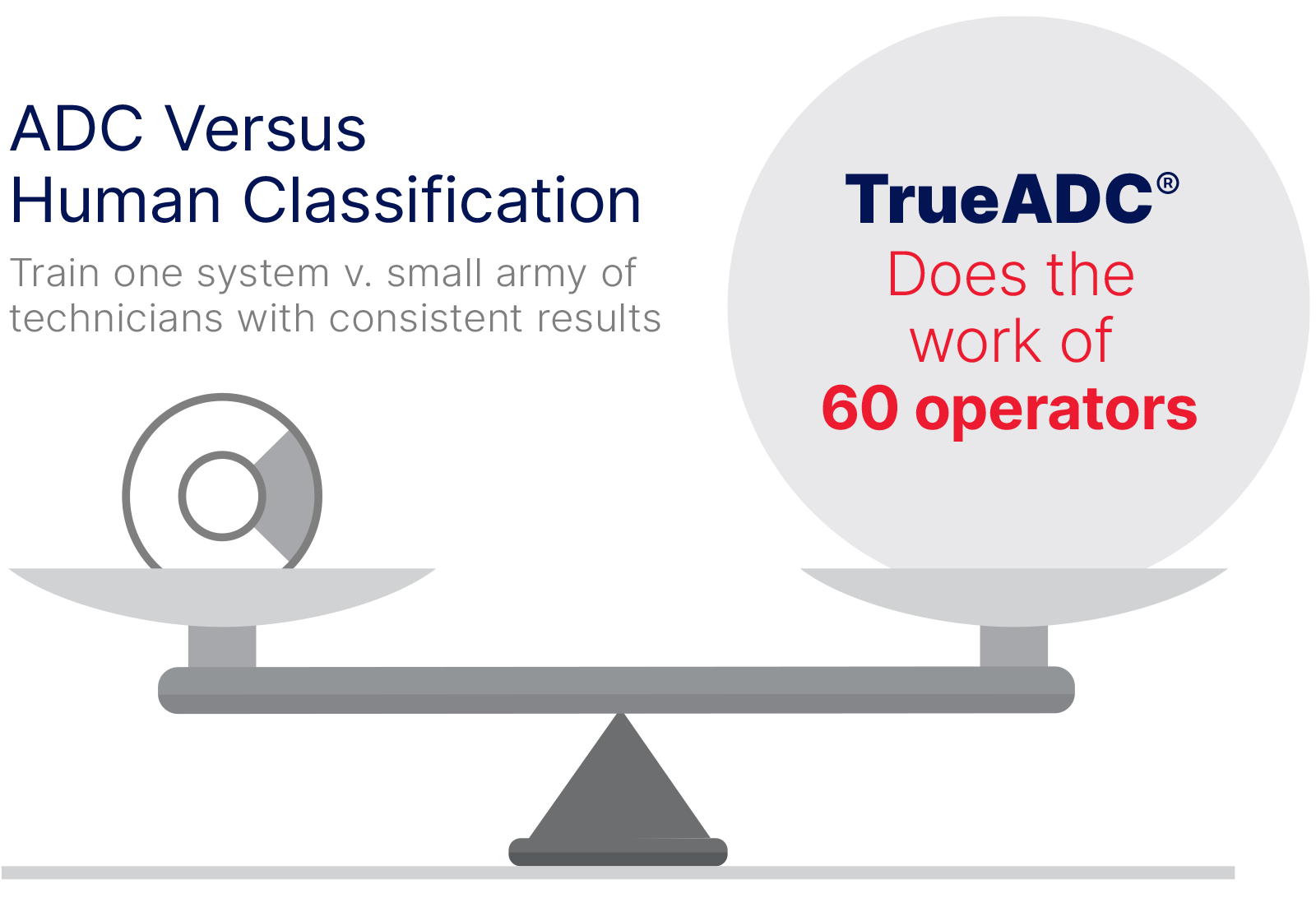

Trust in automation. TrueADC’s multi-engine AI and non-AI modes leads to a matter-of-fact classification; it’s like two operators reviewing the same defect then reaching a consensus based on their overlapping perspective. Re-review of a TrueADC classified defect is a thing of the past.

Preserve your AI investment. Integrate TrueADC with your proprietary classification engines to leverage internal expertise. Adopt and apply different deep learning model architectures. Incorporate 3rd-party models. However you imagine the next level of your DL implementation, consider us your partner.

Maximize value with Onto Innovation. When TrueADC is integrated with Onto AOI tools and our Discover Defect and Discover Review platforms, customers benefit from a proprietary hybrid decision-making process across all wafers and surfaces – delivering the best results in the shortest time possible.

Applications

- Memory

- Logic

- Microprocessor

- ASIC

- Foundry

- Compound-Semi

- HDD

- LED

- Advanced Packaging

- Panel / MCM

Related Products & Markets

Discover Review Software

Your smart factory’s human classification interface

Memory

Memory has become the cornerstone of the electronic world and one of the most critical semiconductor devices manufactured today.

Advanced Packaging

Whether on wafer or panel, fan-out packaging offers reduced package cost and/or form factor.