Avoiding short term and long term failures

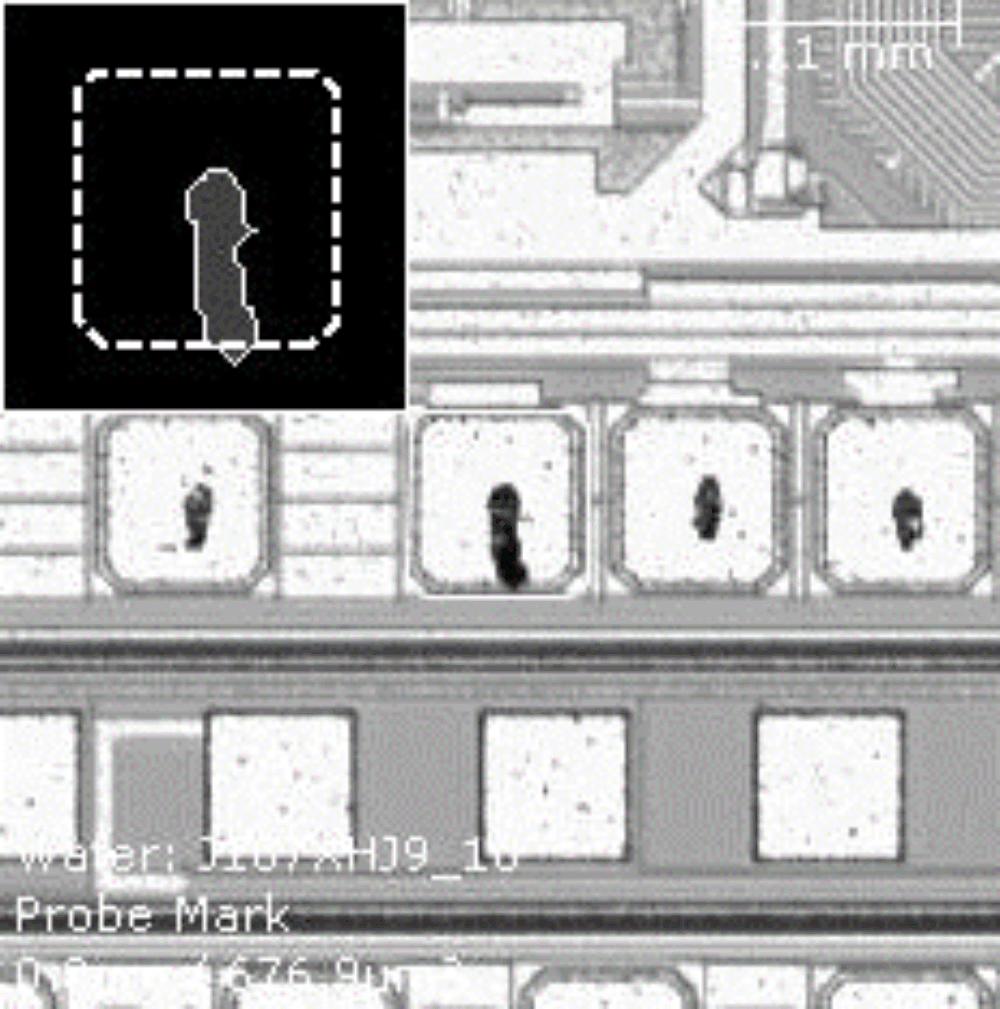

The process of testing can sometimes cause problems on a device that will lead to short term or long term failure. Broken window, punchthrough and missing probe marks are all problems that impact yield immediately. Not only is it necessary to ensure that the probing process did not damage a device to the point of failure, but it is equally important to ensure that the probing process is under control and is not trending toward failure.

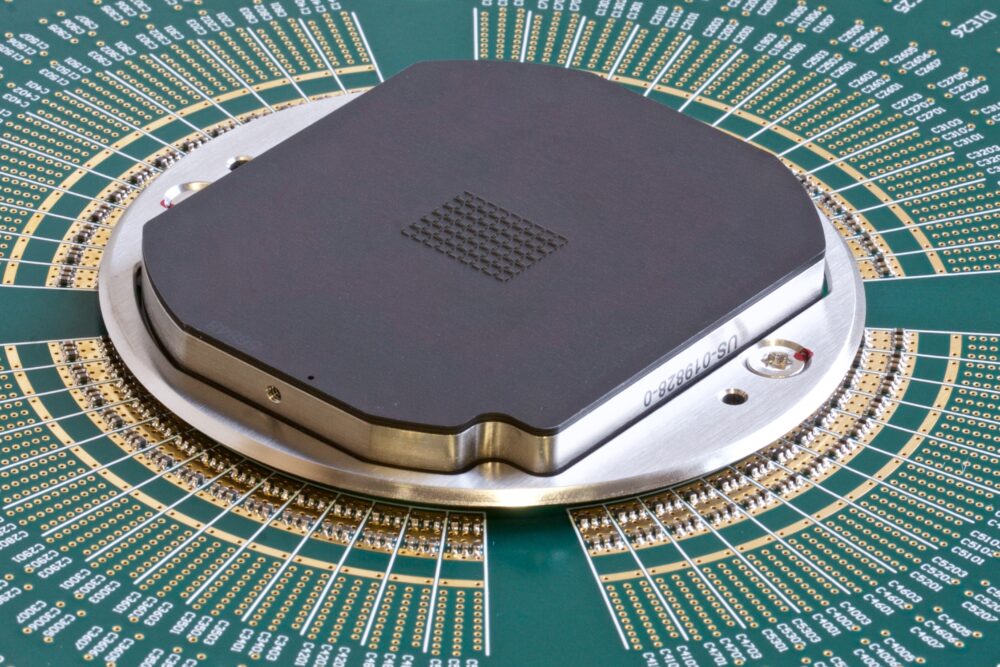

Onto Innovation inspection solutions offer a comprehensive approach to finding probe-related defects, measuring probe marks and driving analysis to simplify the process of optimizing a prober and probe card. Probe mark inspection can automatically detect broken window defects, punchthrough and provide probe mark measurement data during a normal defect inspection. Probe mark measurement data (length, width, position, distance to edge) can be combined with prober touch down maps (Device Under Test) information to quickly and intuitively identify probing problems that originate at the prober or the probe card and can further quantify the exact change that needs to occur to bring the process back into control.