Control of metal deposition and planarization

Chemical mechanical planarization (CMP) is a critical process with applications in the front-end of line (FEOL), middle of line (MOL) and back-end of line (BEOL). Oxide, nitride, & poly silicon CMP steps can be found in FEOL and MOL for shallow trench isolation (STI), inter layer dielectric (ILD), self-aligned contact (SAC) and other process modules. Integrated metrology plays a key role in CMP process control for these FEOL and MOL steps where both under-polishing and over-polishing can lead to yield loss.

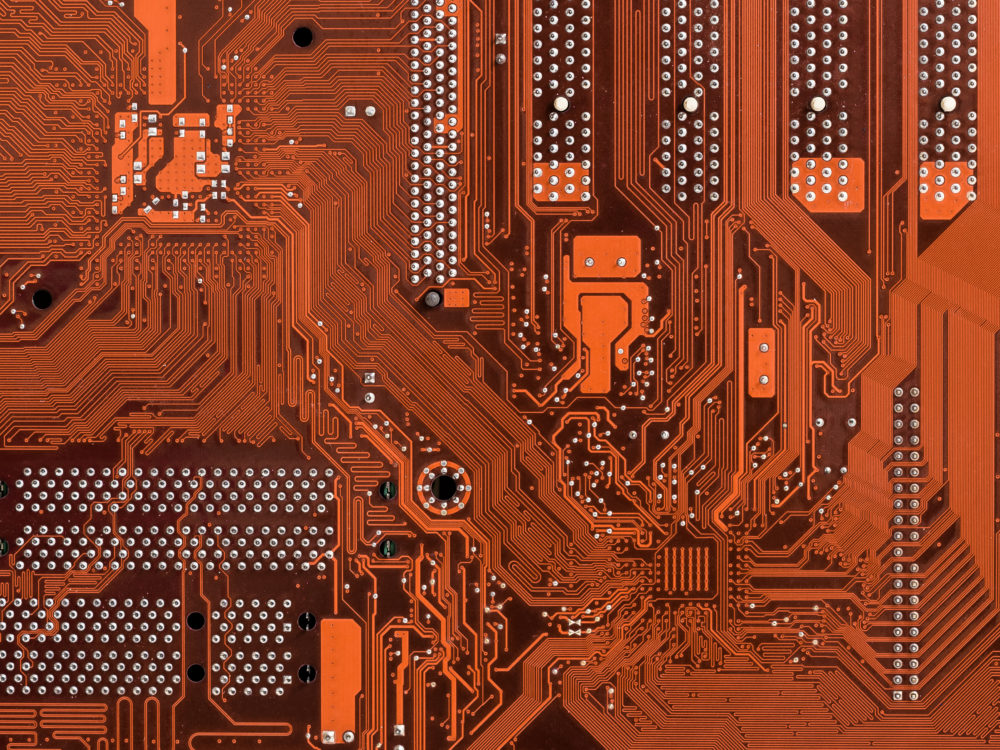

CMP is also critical in the BEOL dual damascene process for creating high performance interconnect structures. If line structures are under polished, residual copper or barrier will short out the circuitry resulting in defective dies. However, over polishing increases the line resistance, negatively impacting both the speed and performance of devices. To maintain high yield, it is critical to maintain the copper lines at the desired thickness. Pre-CMP measurements offer insight into pattern dependent plating effects - Cu overburden as well as trench measurements and can be used to fine tune the process.

Accurate in-line technique for detecting process variations and flagging mis-process of as-plated and post-CMP is critical to understanding yield issues especially at wafer edges.