Presentation posted on Oct 1, 2020

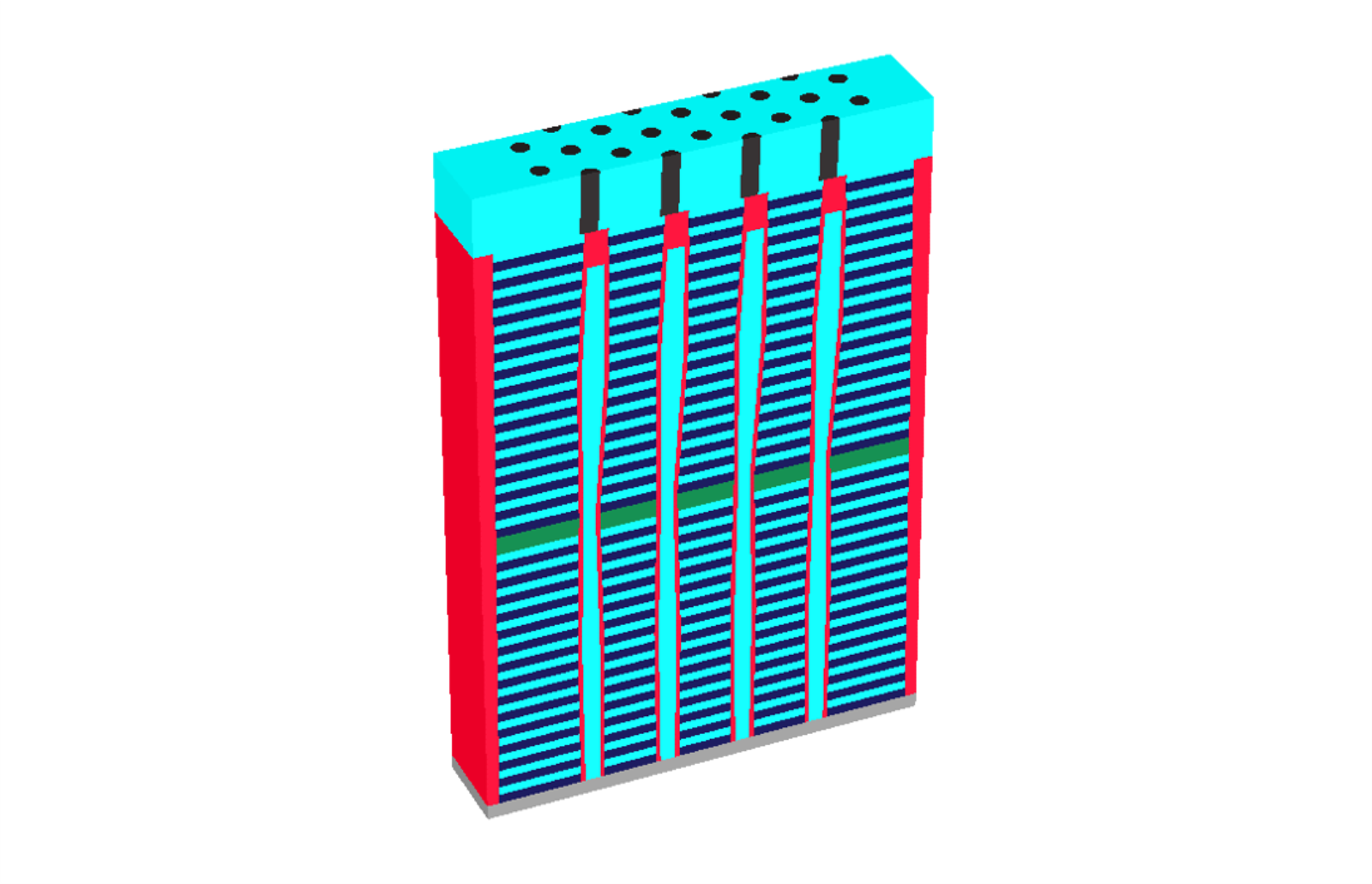

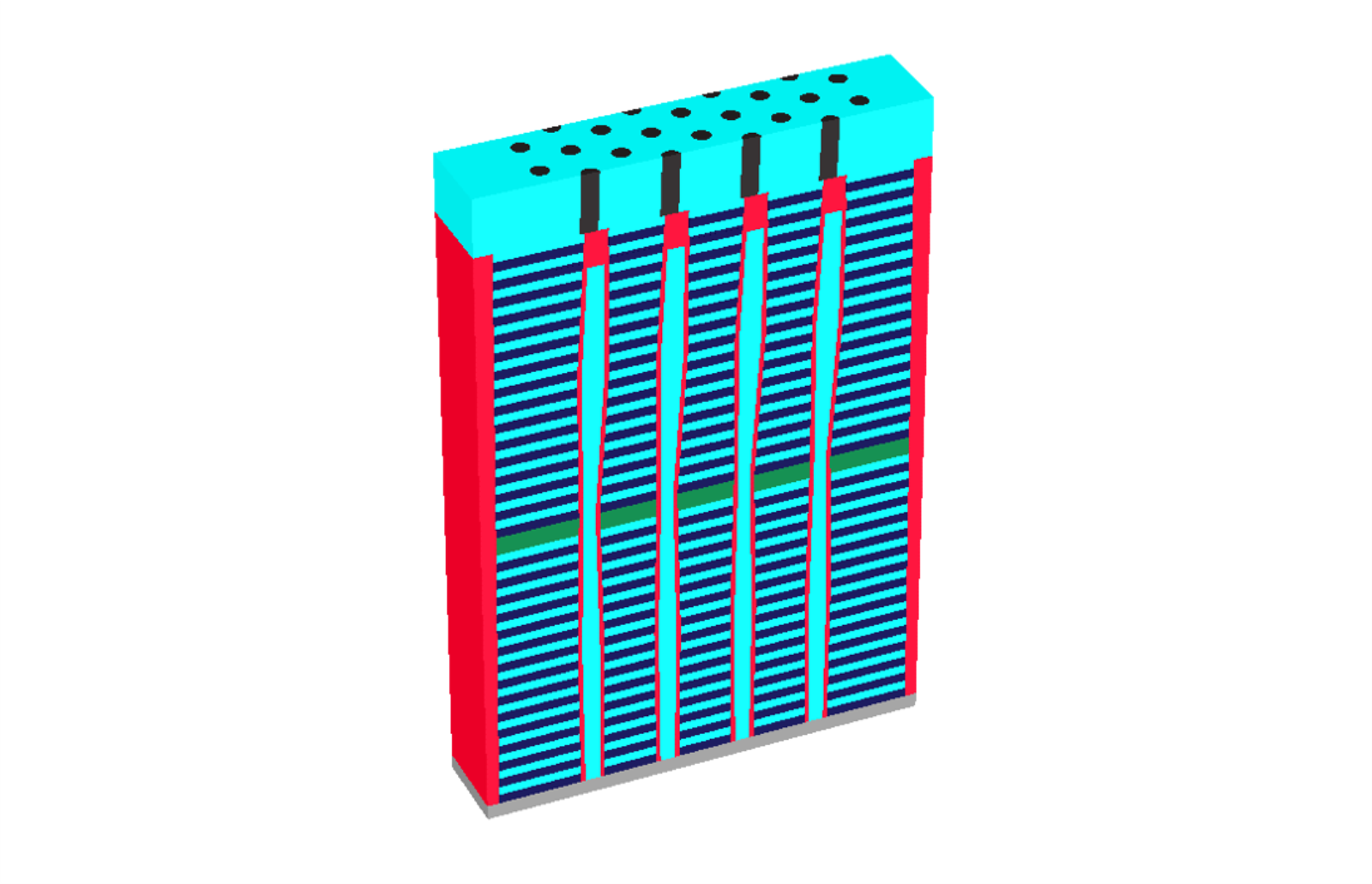

A-Carbon films are critical in the 3D NAND process. Thickness and elastic modulus are important to define channel hole and to tune etch profile, respectively. Multiple metrology tools are used to comprehensively characterize this complex system: