Article posted on Oct 31, 2018

Increasingly dispersed and complex supply chains require a proactive, integrated, systems-level approach to optimizing yields.

As IC manufacturers adopt advanced packaging processes and heterogeneous, multi-chip integration schemes to feed ever-greater consumer demand for more computing power in smaller and smaller spaces, their supply chains have become increasingly complex. A fab-wide view of the process, not so long ago the holy grail of yield management systems, now seems quaintly inadequate.

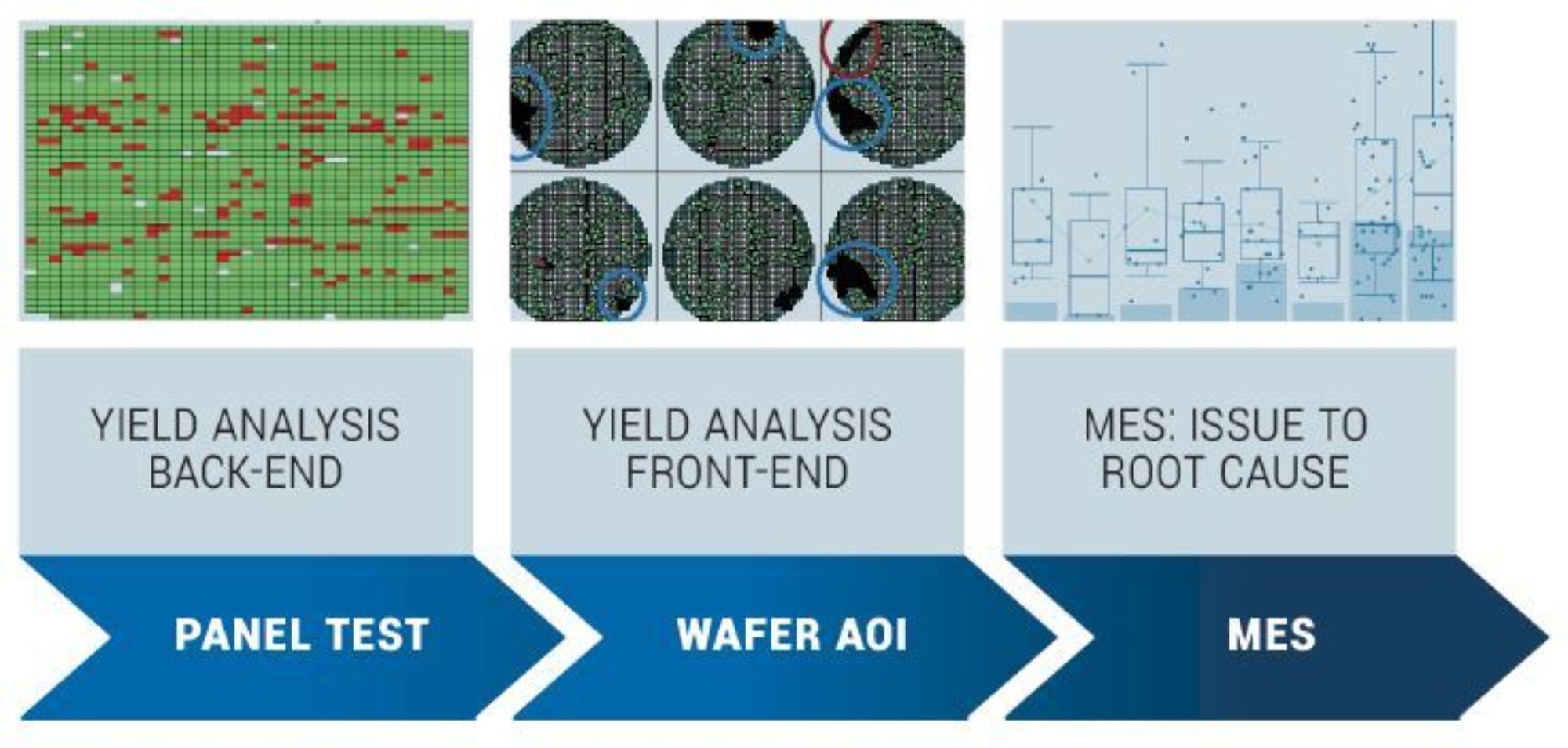

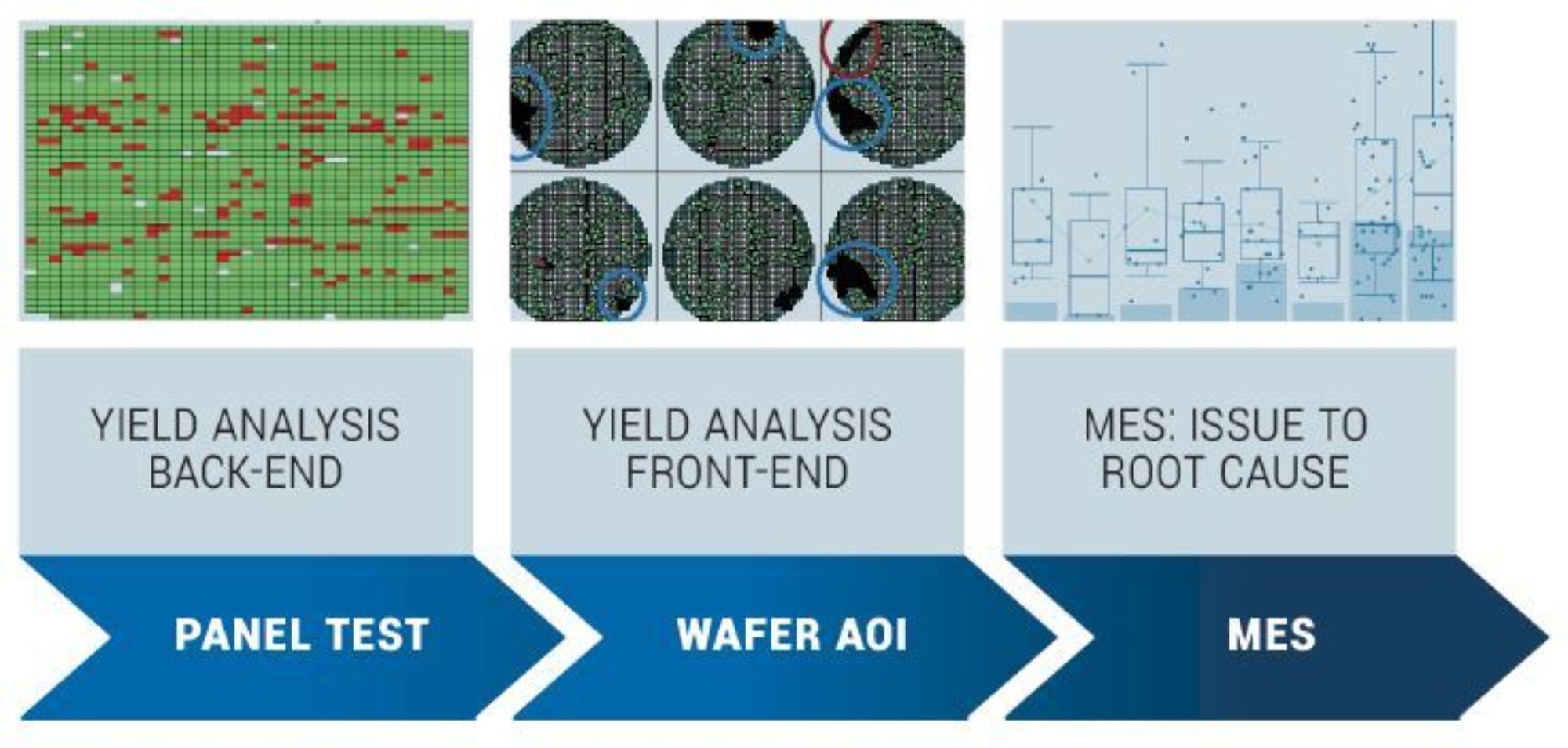

Critical processes that affect finished product yields now occur in different facilities running diverse processes at locations spread around the world. A packaged electronics module may combine microprocessors, memory, MEMS sensors and RF communications, all from different fabs and each with its own particular history. Optimizing yields from such a complicated supply chain requires access to individual component genealogy that includes detailed knowledge of process events, equipment malfunctions and operational parameters, and much more. The latest generation of yield optimization systems consolidates this data – tool deep and supply-chain wide – in a monolithic database, providing end-to-end, die-level traceability, from bare wafer to final module test. Specialized algorithms, designed for “big data” but based on intimate knowledge of semiconductor manufacturing processes, can find hidden correlations among parameters, events and conditions that guide engineers to the root causes of yield losses and ultimately deliver increased fab productivity, higher process yields, and more reliable products.