Blog Post posted on Apr 9, 2024

Automated optical inspection (AOI) is a cornerstone in semiconductor manufacturing, assembly and testing facilities, and as such, it plays a crucial role in yield management and process control. Traditionally, AOI generates millions of defect images, all of which are manually reviewed by operators. This process is not only time-consuming but error prone due to human involvement and fatigue, which can negatively impact the quality and reliability of the review.

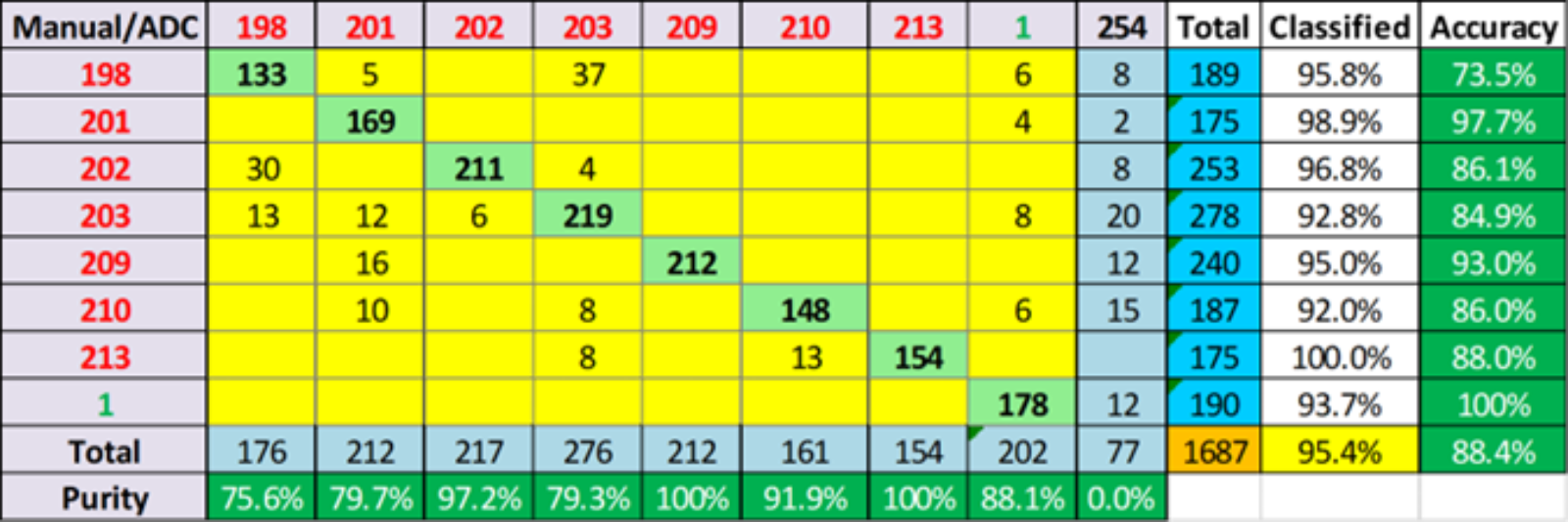

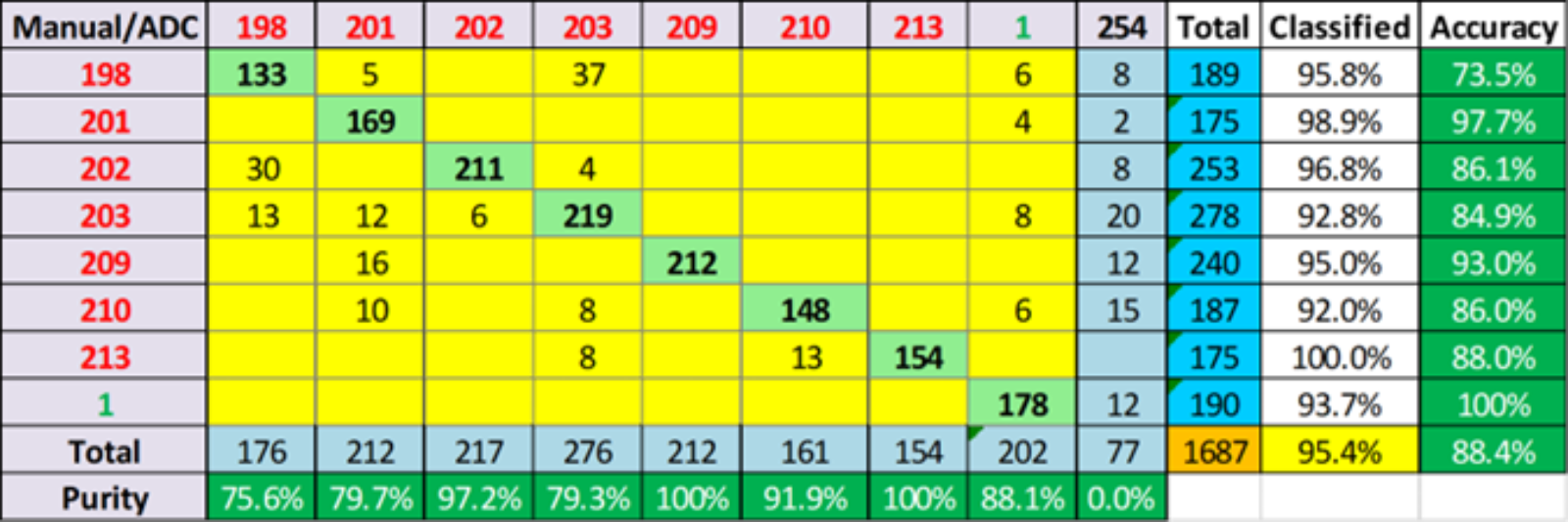

In the Industry 4.0 era, the integration of a deep learning-based automatic defect classification (ADC) software solution marks a significant advancement in manufacturing automation. For one, ADC solutions reduce manual workload – meaning less chance of human error and higher accuracy – and, two, they are poised to lower the costs associated with high-volume manufacturing (HVM).

Deep learning, a branch of machine learning based on artificial neural networks, is at the core of these ADC solutions. It mimics the human brain's ability to learn and make decisions; this enables the system to recognize complex patterns in data without explicit programming. Compared to traditional methods, this approach offers a significant leap in processing efficiency and accuracy.