Article posted on Jun 11, 2025

Optical measurement technology delivers nanometer resolution for real-time roughness analysis.

Surface roughness is the deviation of a surface from its ideal form. The larger the deviation, the rougher the surface. When using a 2D measurement technique, the roughness average is represented as Ra, while it is known as Sa when calculating roughness from 3D area measurements.

Most machined surfaces have an average roughness (Sa) of 200 nanometers (nm) to 2 µm (8 to 80 µin but can go down to less than 25nm. Traditionally, surface roughness has been measured using either subjective visual tests or two-dimensional (2D) stylus tools. For aerospace components, deviations from surface roughness specifications can cause performance issues such as increased wear, fracturing, disrupted fluid or air flow, poor adhesion of coatings and lubricants, and reduced corrosion resistance.

While visual testing techniques are inexpensive and easy to use, they do not deliver quantitative results. They cannot meet the gage repeatability standards many aerospace manufacturers require.

Using a 2D stylus offers quantifiable results, but faces hurdles in meeting gage repeatability standards, especially on the shop floor. The 2D stylus offers only a single trace with limited data points, and the results are directionally dependent-based on whether the scan is performed horizontally, vertically, or at an angle across the sample surface. Measuring corners and odd angles adds further challenges. The resolution of a 2D stylus system also depends on the size of the stylus tip.

Additionally, a 2D stylus is a contact-based tool. It can be damaged when measuring parts, especially at the edges, and can potentially damage the part itself.

Traditional quality control lab 3D optical profilers offer many advantages over 2D tools, including higher resolution, a larger measurement area of 3D data, and a true 3D Sa value. But they are limited by long turnaround times and the need to replicate large parts that do not fit under the microscope. They are also vibration-sensitive and require stable platforms, making them impractical for shop-floors.

The 4Di InSpec SR, addresses these challenges with a portable 3D surface gauge that delivers microscope-quality nanometer resolution measurements in real time. With a field of view of 1mm x 0.8mm, the measurement system acquires millions of data points in a single area, with a roughness accuracy of <0.5%, and can measure machined surfaces from mirror-smooth to sandpaper-rough.

The system enables in situ surface finish and roughness measurements below 25 nanometers in seconds, while meeting gage repeatability standards. Machinists can achieve surface finishes at very small scales, creating performance improvements whether the part is a turbine blade or rivet on a wing.

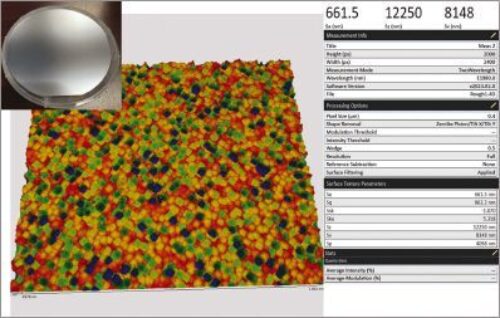

The 4Di InSpec SR displays the surface roughness of a bare wafer

The 4Di InSpec SR measures roughness on large components without the need for replication by bringing the system directly to the part. Its scratch-free optical technology eliminates surface damage concerns. The system employs vibration-immune technology, enabling fast quantification of surface roughness for both smooth and rough components on the shop floor.

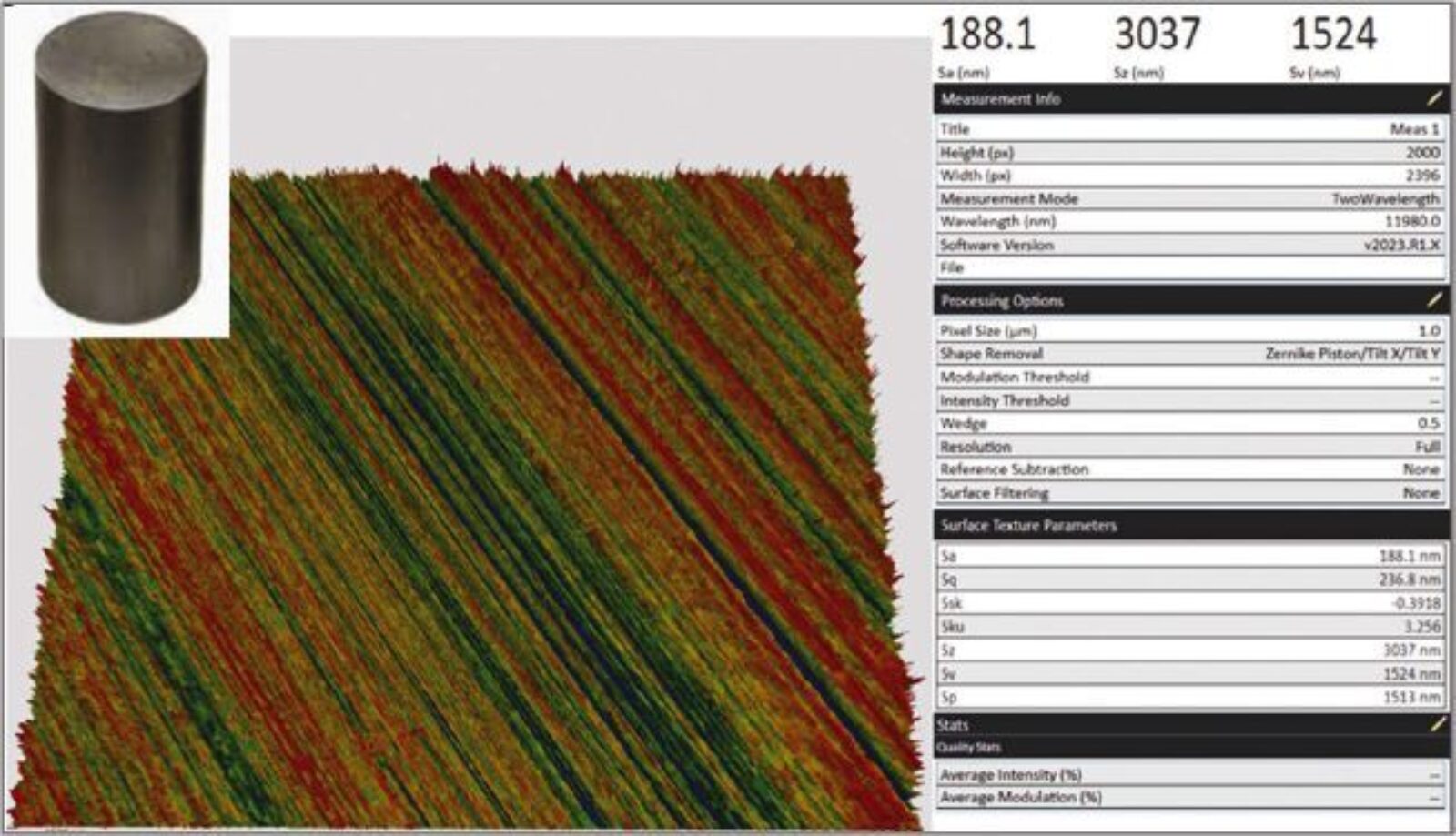

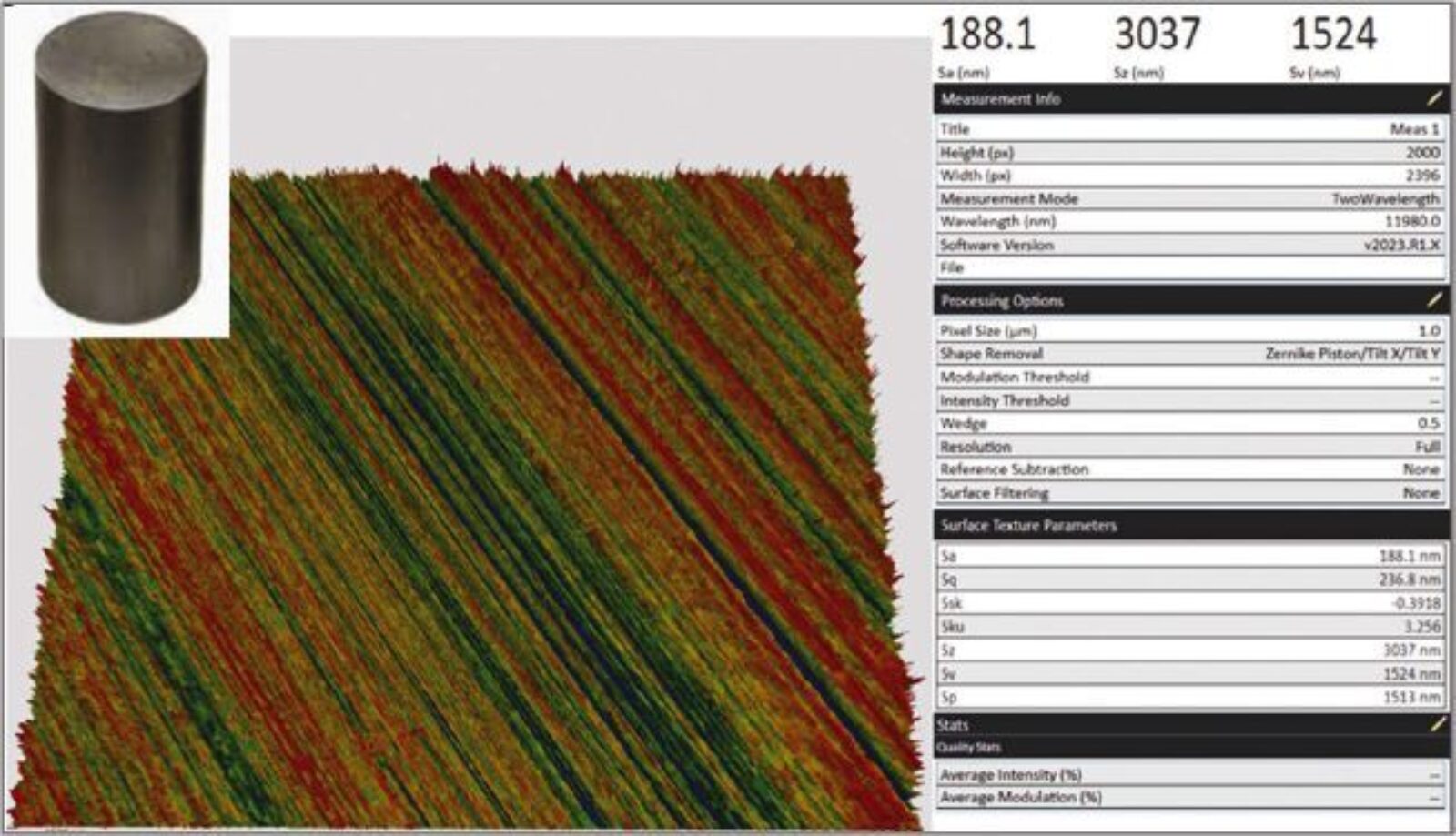

3D roughness at 188nm on a machined metal component

A significant capability of the 4Di InSpec SR is its robot compatibility for automated measurements. Looking to the future, there are numerous opportunities to extend its benefits in shop floor applications, including automation integration, multi-sensor systems for macro and micro level measurements, and advanced predictive analytics capabilities.

The 4Di InSpec SR represents a significant advancement in quality control technology, offering aerospace manufacturers a unique real-time, shop floor surface measurement solution that bridges the gap between traditional laboratory precision and production-line practicality.