Presentation posted on Apr 9, 2017

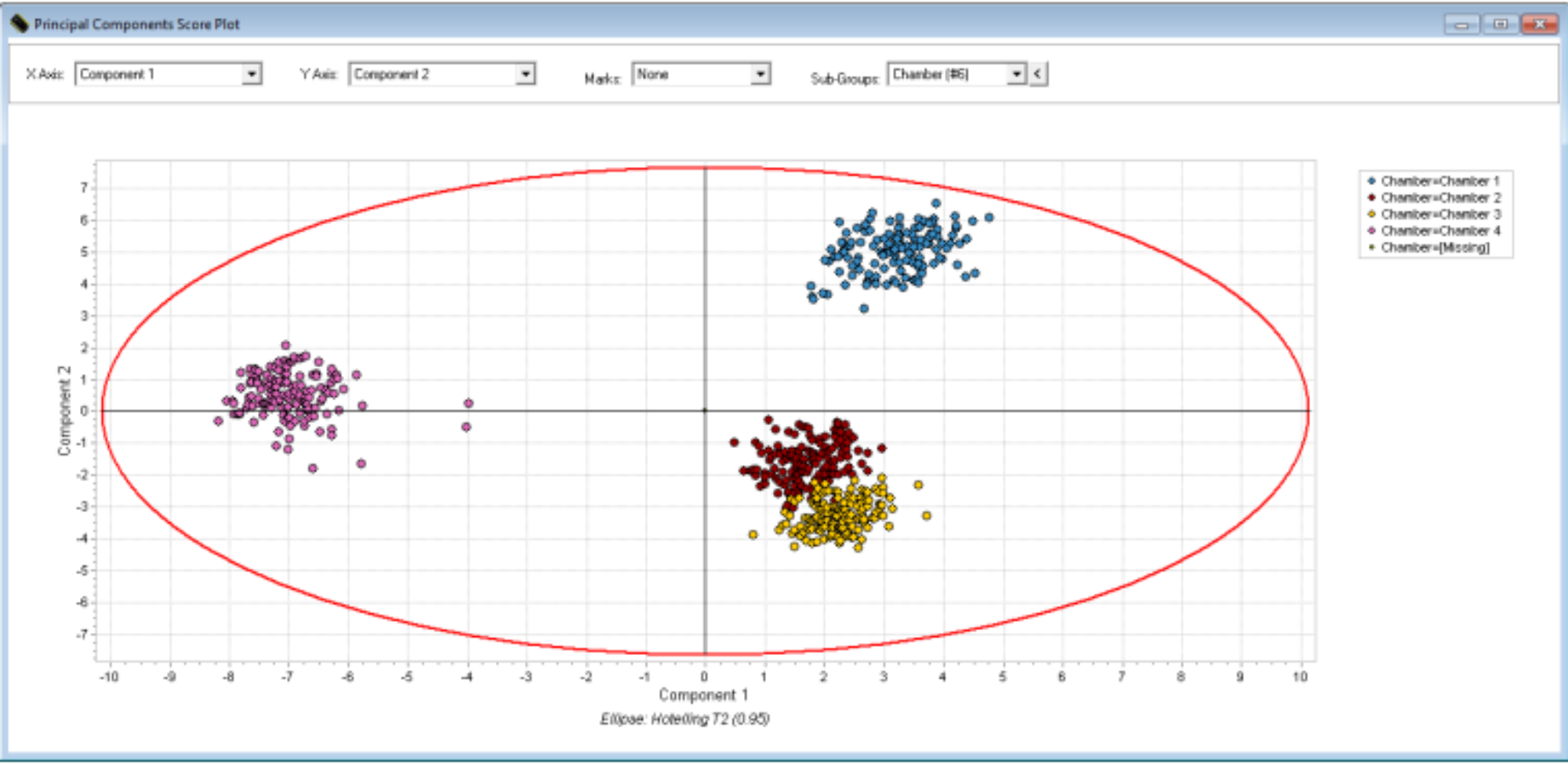

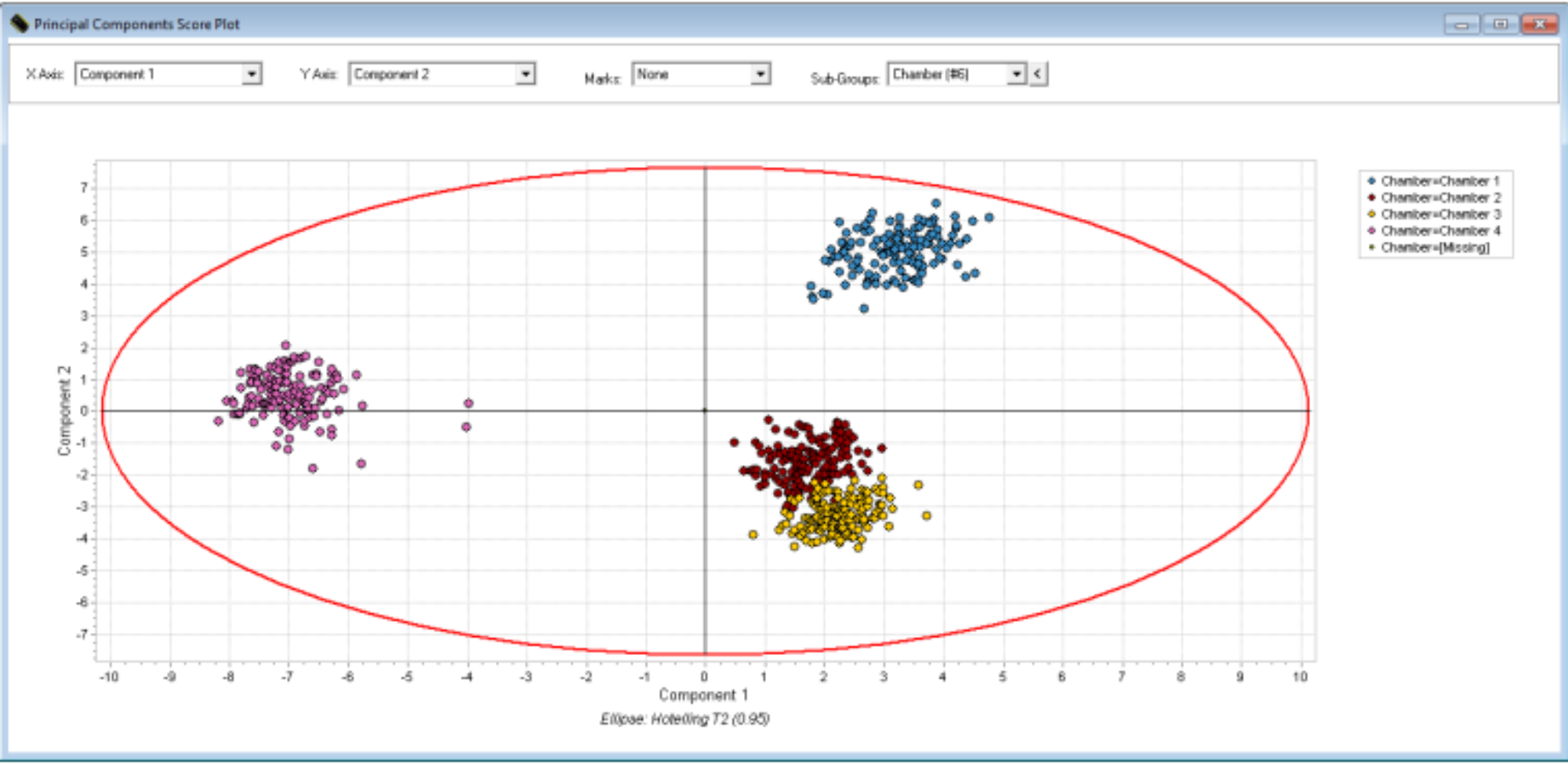

Fault Detection and Classification (FDC) tools provide a powerful source of data from manufacturing tools. Often this data is somewhat chatty, with vast amounts of data about the operating regime of the tool, on hundreds of sensors. While it may be quite simple to compare the data from chamber-to-chamber, this approach may produce many signals, some of which have no impact on product quality. Further, there is a danger that simple SPC approaches lead to an excessive number of false alarms, overloading the engineering teams and leading to reduced responsiveness over time. This paper addresses the use of manufacturing quality data to create Intelligent Digital Signatures that quantify the impact of excursions on product quality and provide a quantitative metric to guide the response teams.