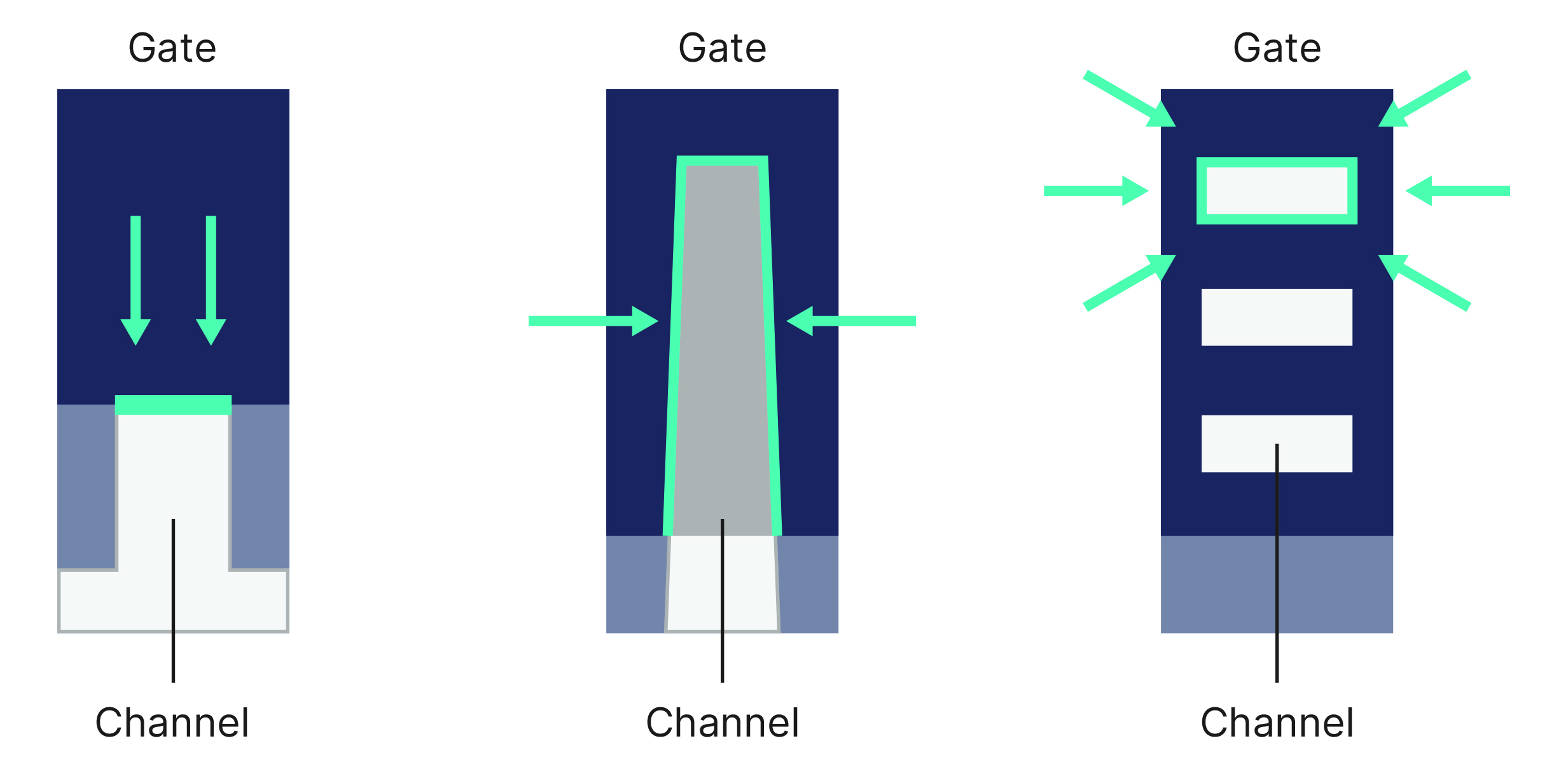

Metrology Solutions for Gate-All-Around Transistors in High Volume Manufacturing

Gate-all-around (GAA) transistors offer significant performance advantages at advanced nodes, but only at the cost of significant increases in process complexity. Complicated three-dimensional structures and shrinking critical dimensions make precise, accurate metrology in GAA manufacturing processes both more important and more challenging. Scatterometry-based optical critical dimension (OCD) metrology has become mainstream in the last several generations of semiconductor development, in part because of its ability to measure three dimensional shapes and subsurface/re-entrant features. The latest generation of OCD systems combines improvements in signal-to-noise ratios, signal fidelity and advanced machine learning capabilities that allow it to support the most challenging GAA process steps with repeatable measurements and production worthy throughput.