Illumination Inspection Technology for Defect Detection on Advanced IC Substrates

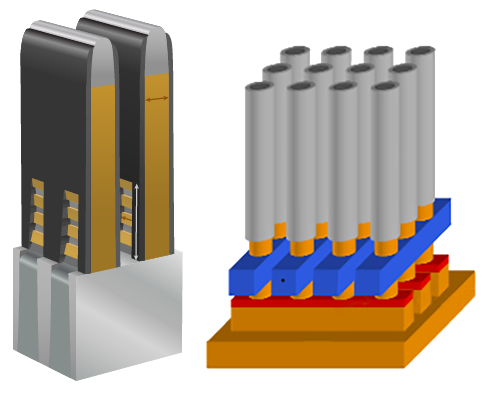

Across the semiconductor industry, advanced integrated circuit (IC) substrate (AICS) supplies are low. The causes vary, from a limited number of suppliers who can meet performance requirements, to constrained production capacities, and increased demand resulting from the adoption of high-performance mobile devices, as well as advanced technologies like artificial intelligence (AI) and high-performance computing (HPC). And without question, the ongoing shortage of Ajinomoto buildup film (ABF), a necessary component of many AICS, plays a significant role as well. One area where this shortage of ABF and AICS is having a significant impact is in the manufacturing of flip-chip ball grid array (FC-BGA) packages—the most advanced substrates to meet the electrical and thermal requirements for IC chips with high numbers of I/Os.

To address the substrate shortage, suppliers of FC-BGA substrates are ramping up capacity. However, that acceleration comes with high costs due to the fact that the AICS process is burdened by low yields resulting from the presence of defects that are left undetected by many macro inspection systems. Furthermore, that inability to detect certain defects is potentially magnified as each new layer of ABF on the FC-BGA substrate is built up. In some cases, the number of layers of build-up may reach 20. With each additional layer, the potential for killer defects increases, whether the cause is ABF residue in laser-drilled vias, poor dry-film resist development, or the under and over-etching of Cu seed.