Article posted on Jun 14, 2022

Over the past ten years, primarily driven by a tremendous expansion in the availability of data and computing power, artificial intelligence (AI) and machine-learning (ML) technologies have found their way into many different areas and have changed our way of life and our ability to solve problems. Today, artificial intelligence and machine learning are being used to refine online search results, facilitate online shopping, customize advertising, tailor online news feeds and guide self-driving cars. The future that so many have dreamed of is just over the horizon, if not happening right now.

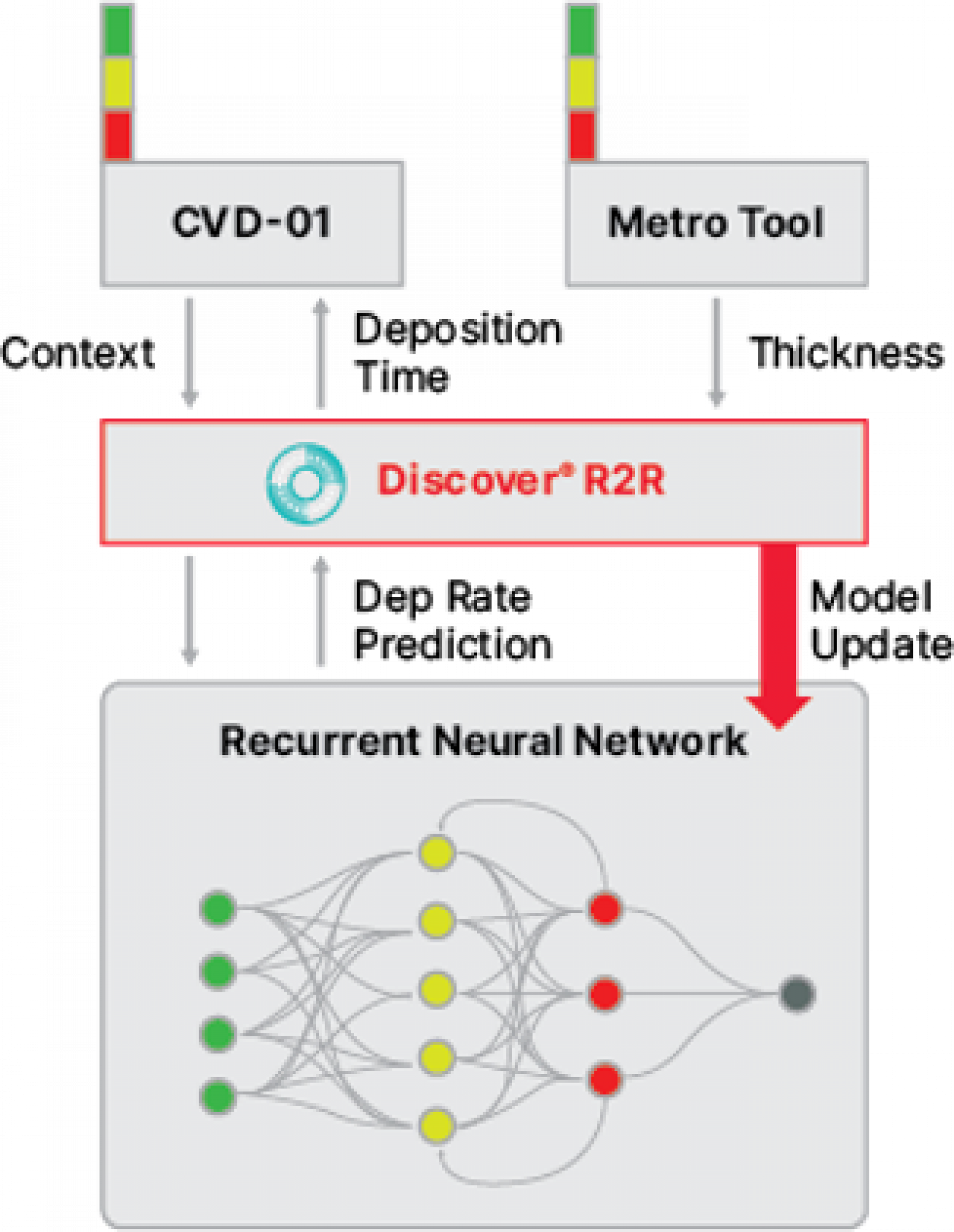

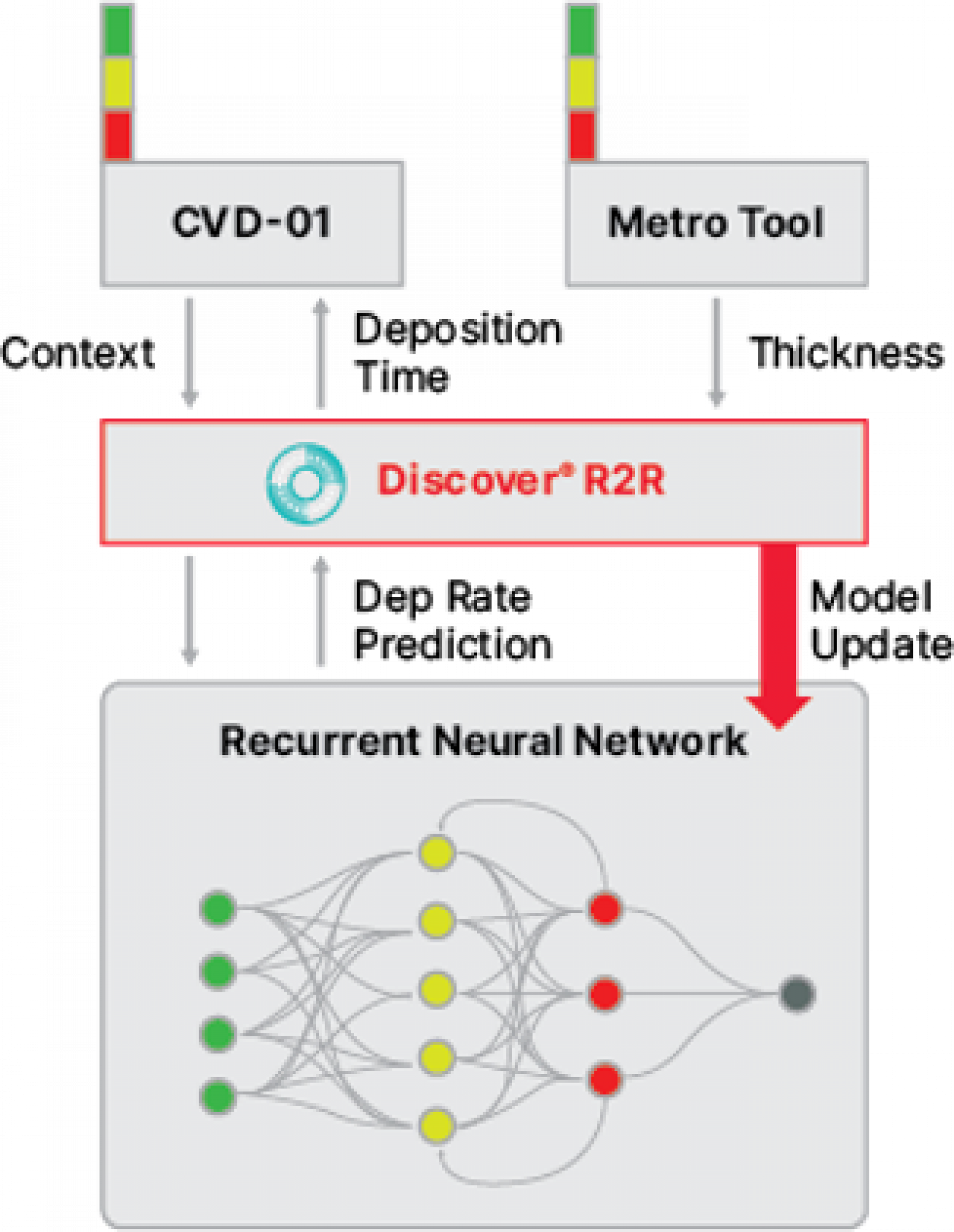

The term artificial intelligence was first introduced in the 1950s and used famously by Alan Turing. The noted mathematician and the creator of the so-called Turing Test believed that one day machines would be able to imitate human beings by doing intelligent things, whether those intelligent things meant playing chess or having a conversation. Machine learning is a subset of AI. Machine learning allows for the automation of learning based on an evaluation of past results against specified criteria. Deep learning (DL) is a subset of machine learning (FIGURE 1). With deep learning, a multi-layered learning hierarchy in which the output of each layer serves as the input for the next layer is employed.

Currently, the semiconductor manufacturing industry uses artificial intelligence and machine learning to take data and autonomously learn from that data. With the additional data, AI and ML can be used to quickly discover patterns and determine correlations in various applications, most notably those applications involving metrology and inspection, whether in the front-end of the manufacturing process or in the back-end. These applications may include AI-based spatial pattern recognition (SPR) systems for inline wafer monitoring [2], automatic defect classification (ADC) systems with machine-learning models and machine learning-based optical critical dimension (OCD) metrology systems [1][7].