White Paper posted on Jul 22, 2021

The growing demand for heterogeneous integration is driven by the 5G market that includes smartphones, data centers, servers, HPC, AI and IoT applications. Next-generation packaging technologies require tighter overlay to accommodate a larger package size with finer pitch chip interconnects on large format flexible panels.

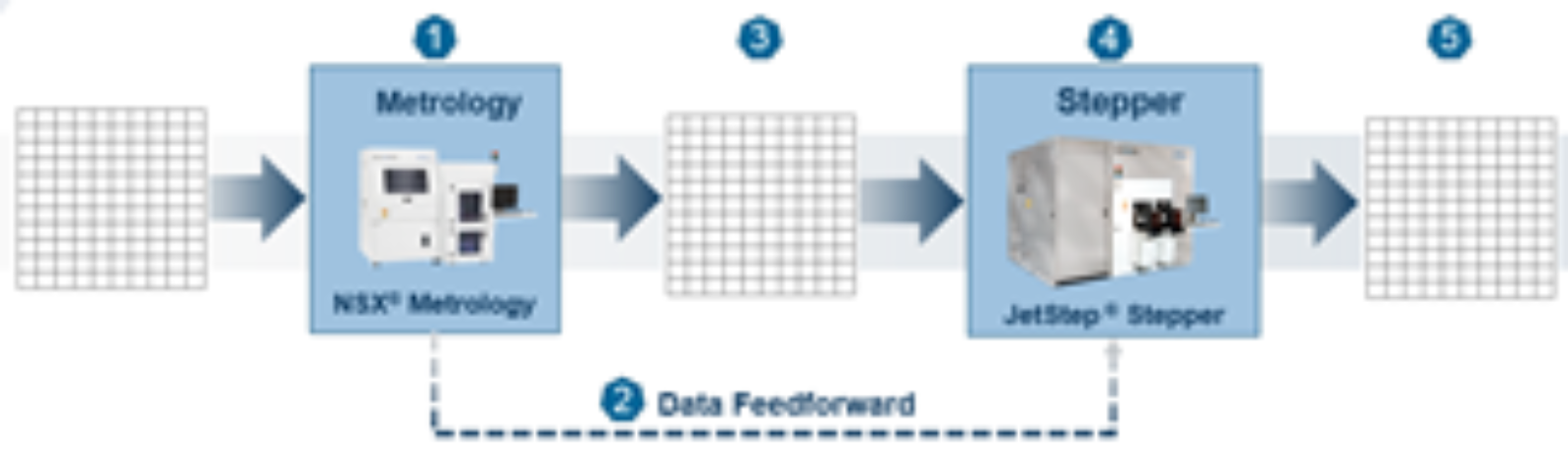

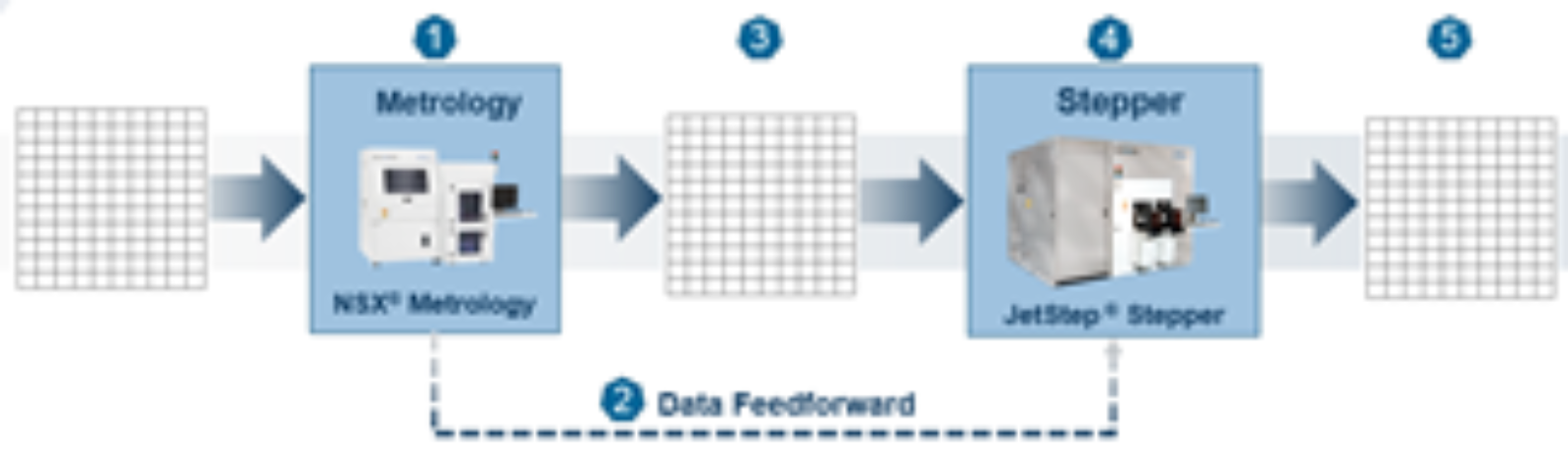

Fan-out panel level packaging (FOPLP) is one of the technologies that is able to achieve market requirements, but also faces several signification processes challenges. One critical challenge for FOPLP is die placement error, which is a result of the reconstitution process. Die placement error can cause high overlay error, which induces low overlay yield. To address this situation, site by site correction exposure with feedforward lithography is proposed. Site by site correction exposure can overcome the die placement error to achieve an acceptable overlay yield, and feedforward lithography is used to improve the throughput when using site by site correction exposure. An issue was observed when using feedforward site by site correction method: when one or more reconstituted dies suffered large displacement error, these large error dies affect the correctable accuracy of the site and induce poor overlay to all the dies in the site. To address this issue, which could induce poor overlay, advanced outlier control technology is proposed. Advanced outlier control technology is used for identifying the large error dies and processing these large error dies to prevent the situation.

In this paper, we demonstrated advanced outlier control technology with feedforward lithography on a selected test vehicle, which is a 510 mm x 515 mm panel. 400 simulation dies were built on this panel and part of the dies were designed with a large displacement error. The panel was processed using advanced outlier control technology with feedforward lithography in the demonstration. This demonstration showed how these two technologies integrated together and how this integration strategy worked for the FOPLP process. We also review and discuss the results for how this integration technology can maintain yield and throughput under such challenging conditions.