The Power of

Connected Thinking

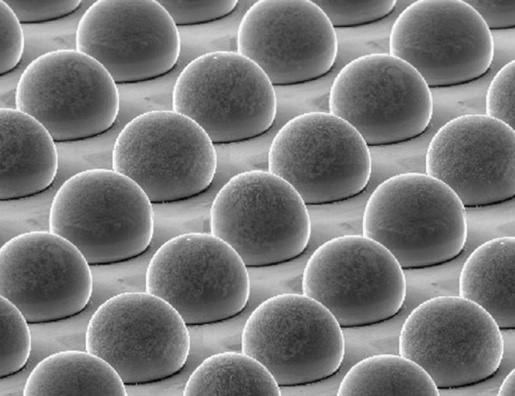

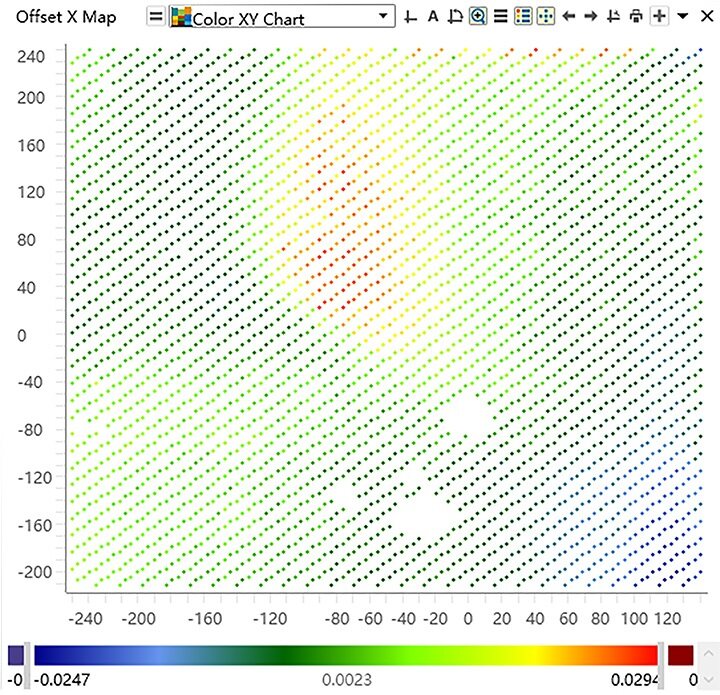

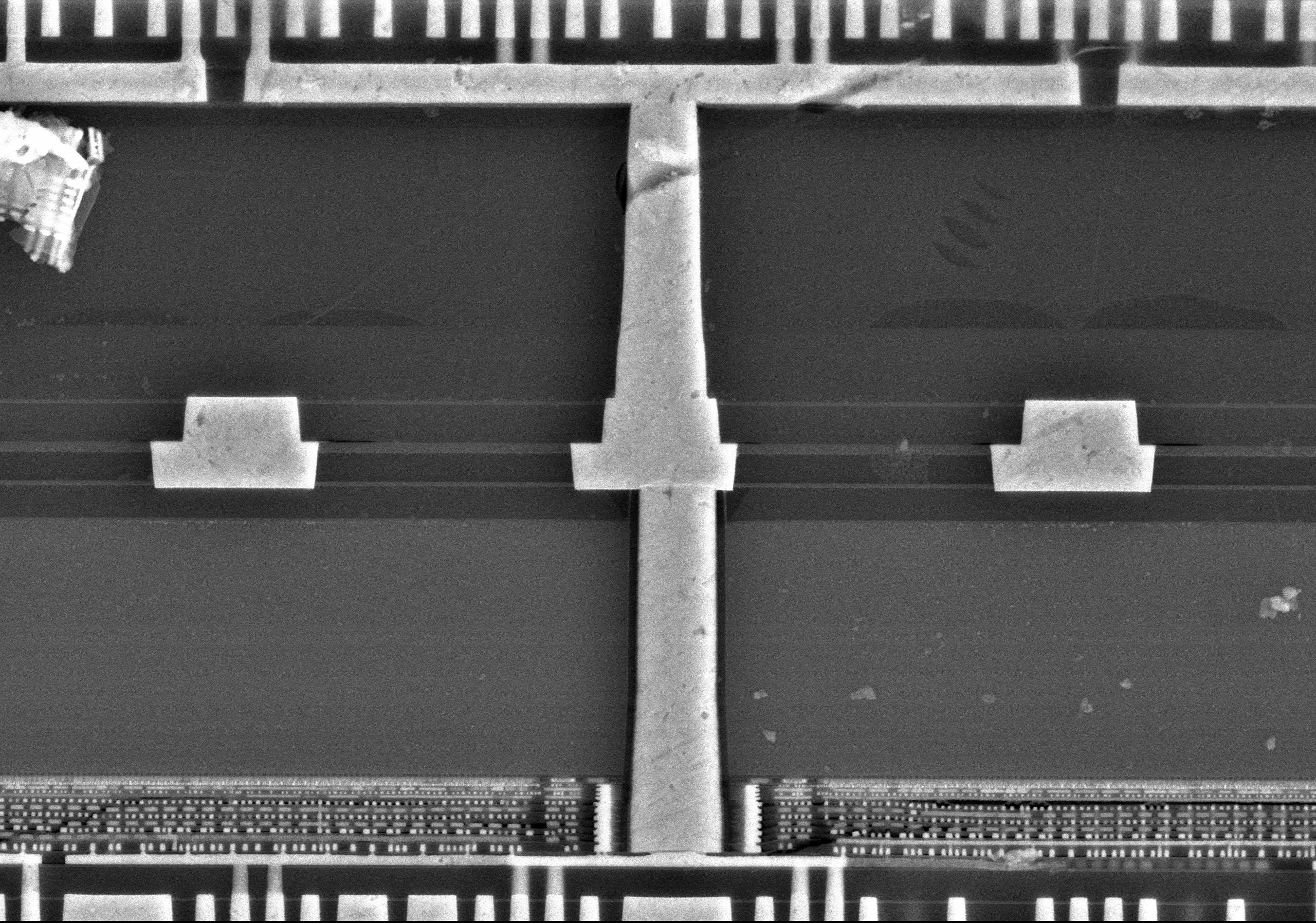

Onto Innovation provides comprehensive process solutions across the semiconductor value chain, specializing in inspection, metrology, lithography and software. Solving our customers’ most complex challenges, enabling a more innovative future.

Join our future focused team today

Are you a passionate innovator ready to help shape the future of what technology can achieve? Join us at the forefront of semiconductor innovation, where your ideas can power the world of tomorrow.