Firefly® G3 System

The Firefly G3 system provides automated inspection and 3D metrology for advanced IC substrates and panel level packaging, delivering high resolution and productivity for demanding applications like high-performance computing (HPC), artificial intelligence (AI), cloud computing and machine/deep learning.

Product Overview

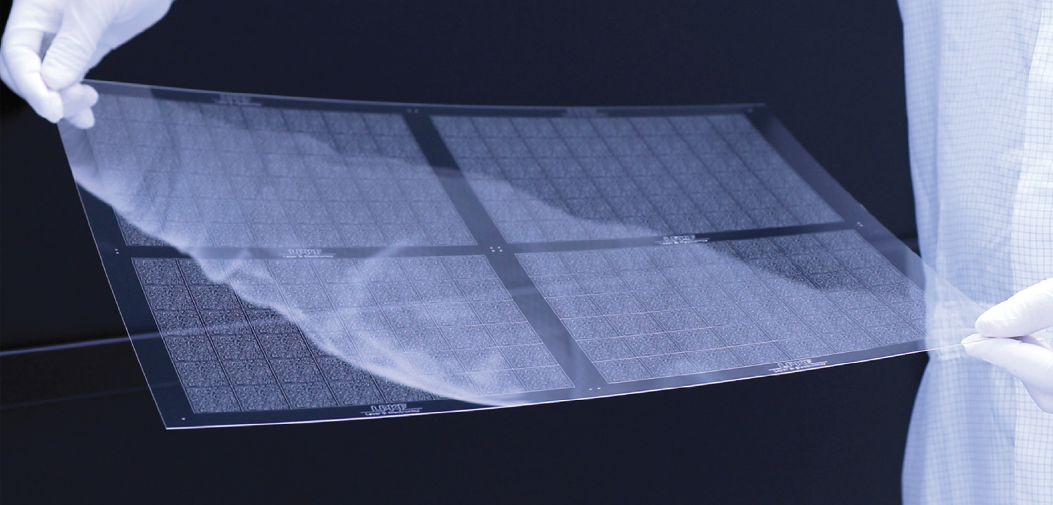

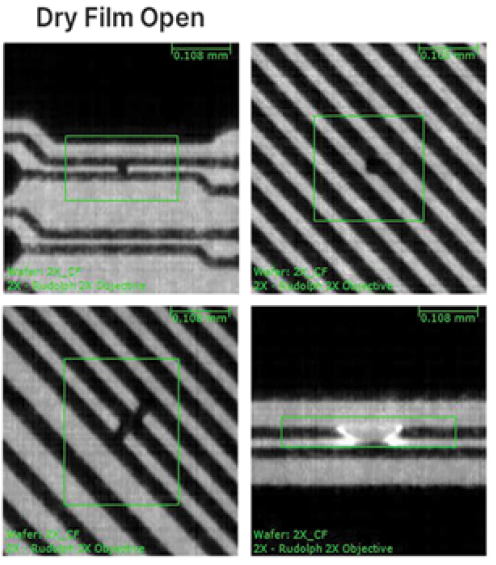

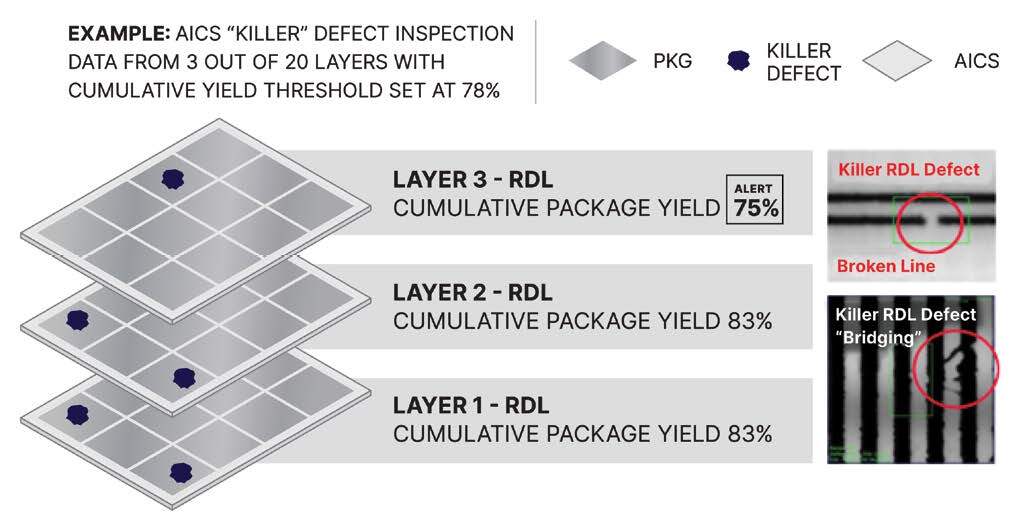

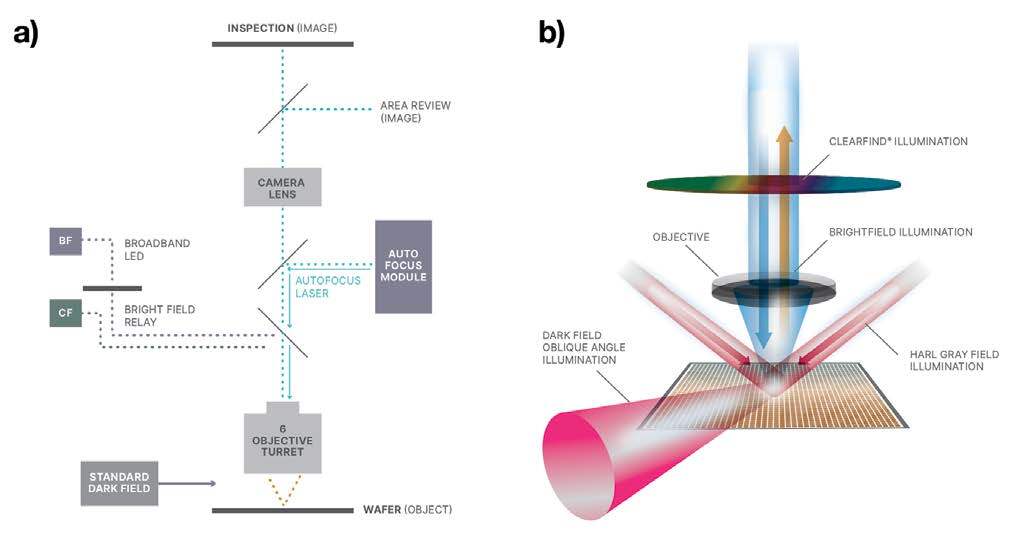

The Firefly G3 platform offers multiple imaging modes, including Onto Innovation’s patented Clearfind® Technology, a technique to detect residue defects on metal and metal defects on organic layers. The combination of high sensitivity inspection, 2D/3D metrology and on tool color image capture capability in a single platform reduces capital investment requirements and provides a reliable pathway for panel-based process applications that require high I/O counts and multiple-chip integration.

Integration with Onto Innovation’s Discover® Defect and TrueADC® software quickly turns defect data into actionable process control, improves defect classification and reduces manual review. It enables our customers to develop, learn and analyze new processes reliably while significantly improving their product delivery time to market.

Applications

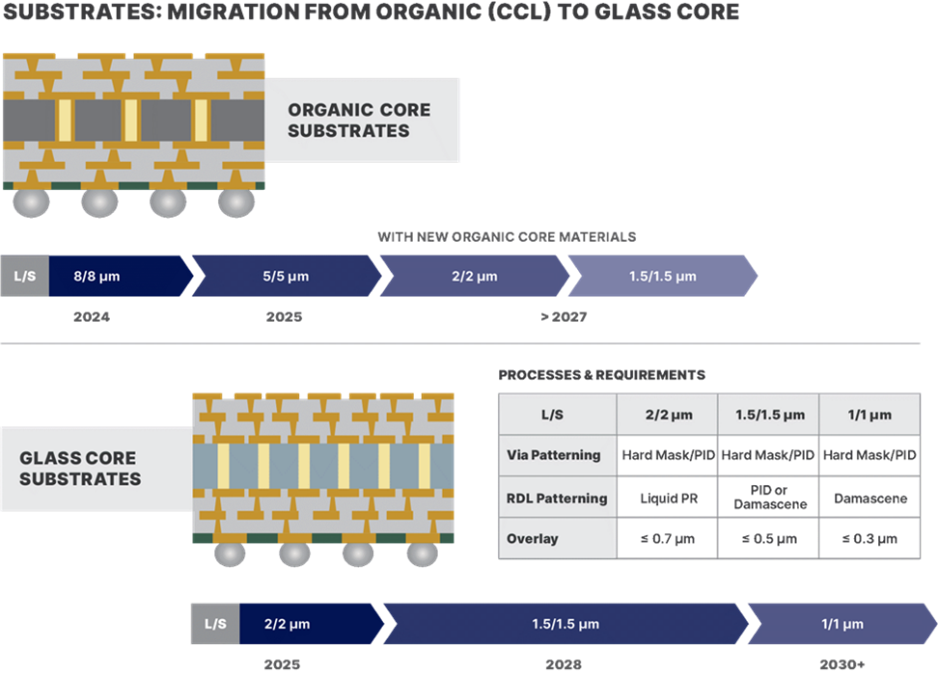

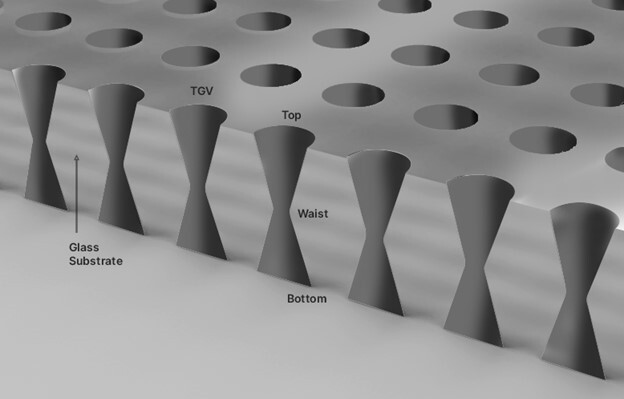

- Advanced IC Substrates (AICS): CCL and Glass

- Fan-out Panel Level Packaging (FOPLP)

- Interposers

- Embedded Die substrates/ Interposer

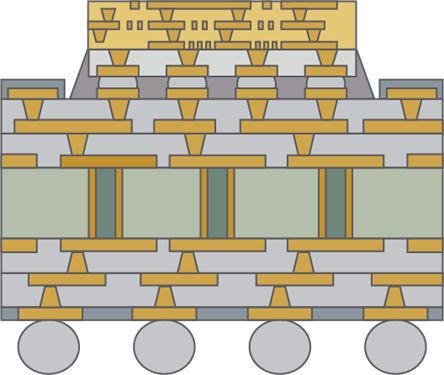

- 2.5D/3D integration

Featured Markets

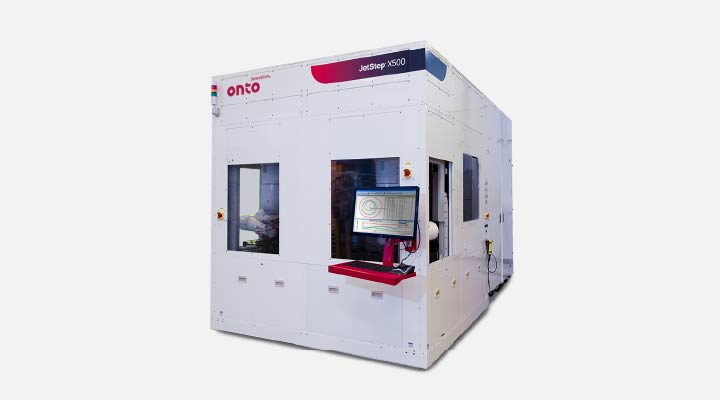

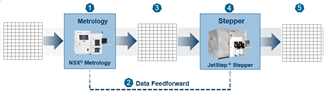

Adaptive Shot Lithography Solution

Die shift on reconstituted panels can significantly impact both productivity and yield. To address this challenge, we use a parallel die placement measurement process and advanced analytics to provide a means to balance productivity against yield. Our integrated lithography cell, featuring Firefly inspection, StepFAST software, and JetStep Lithography, delivers industry-leading throughput and yield for fan-out panel level packaging.

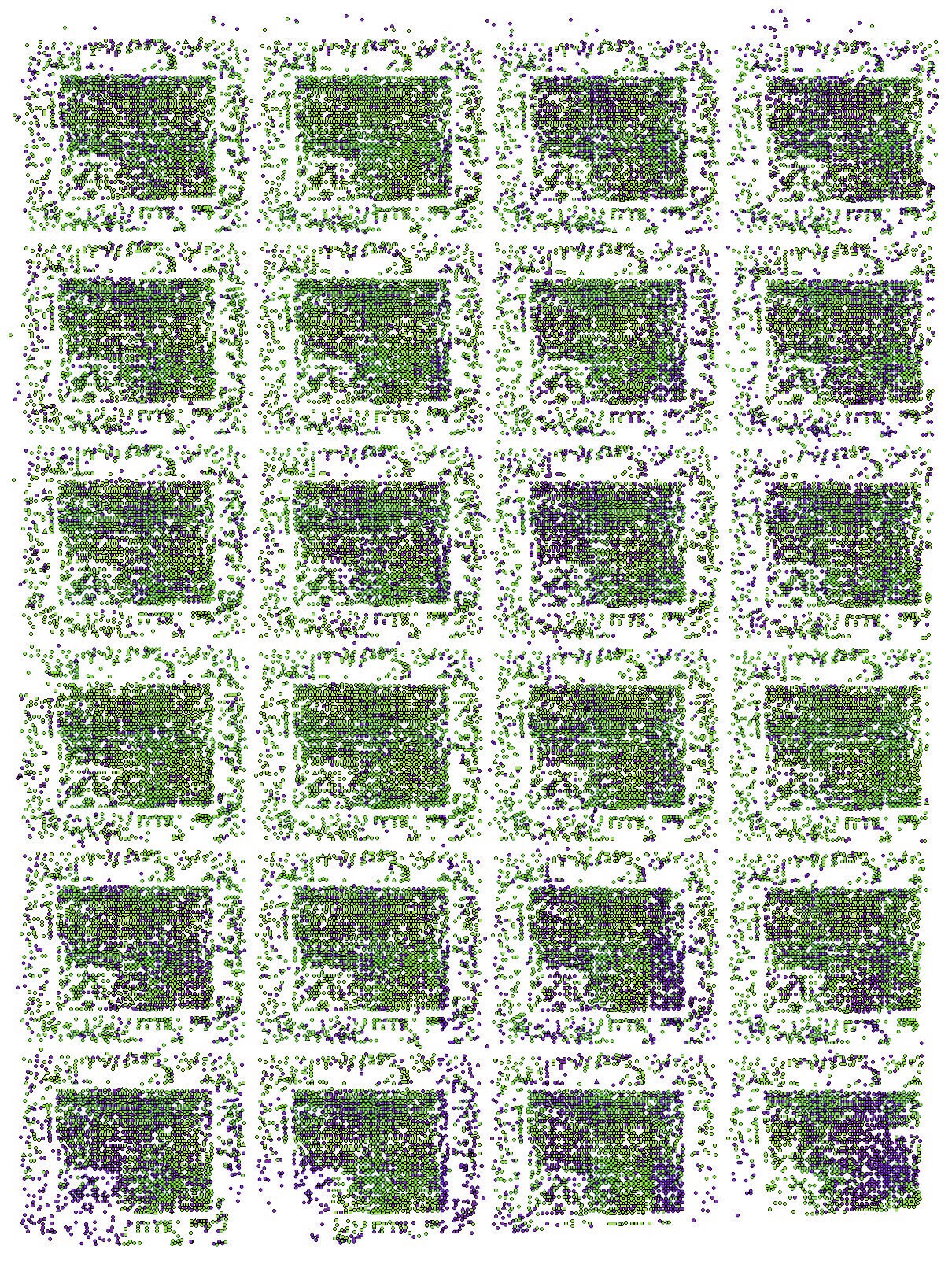

Overcoming FOPLP Die Placement Error

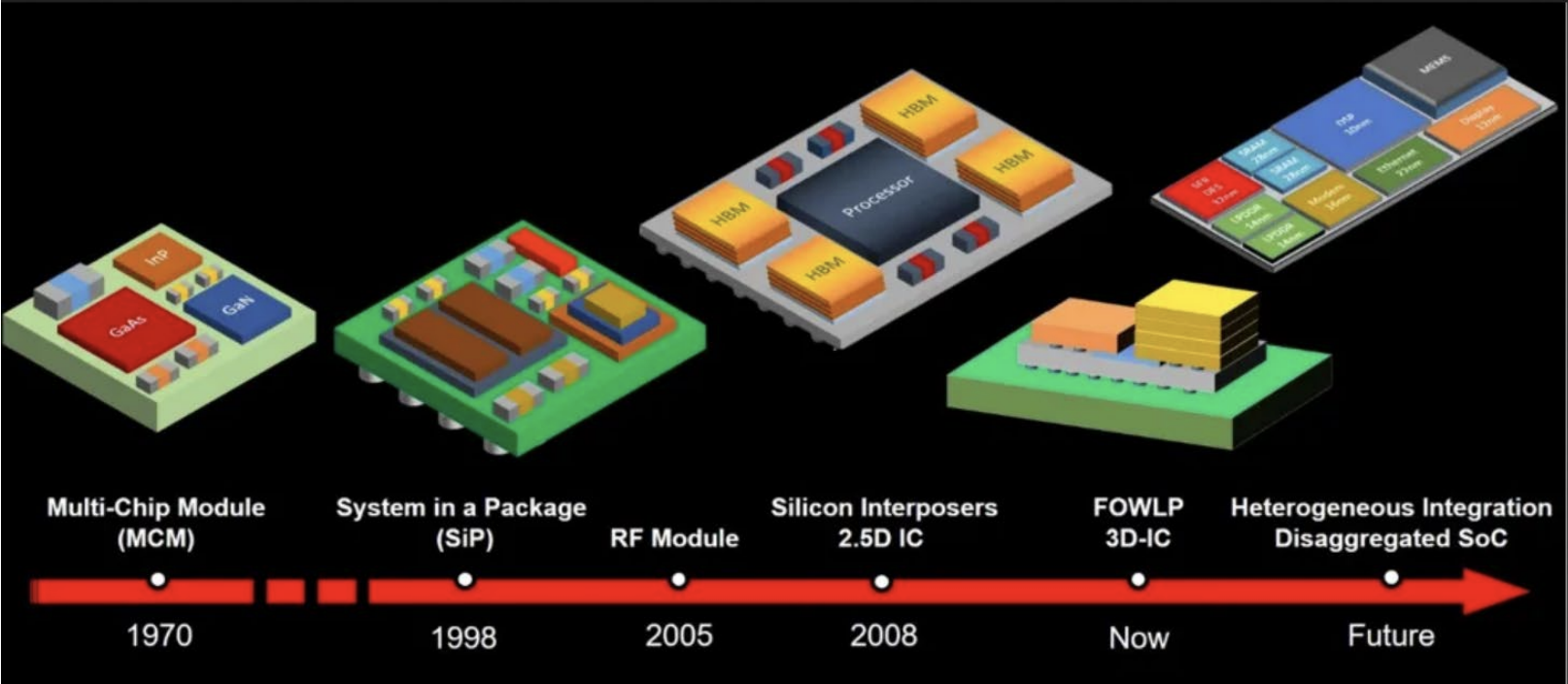

It is well understood that advanced packaging applications require high performance, low cost, increased functionality and improved reliability that 2.5D and 3D packaging solutions provide. Fan-out panel-level packaging (FOPLP) is one of the technologies that has the potential to meet these packaging requirements.

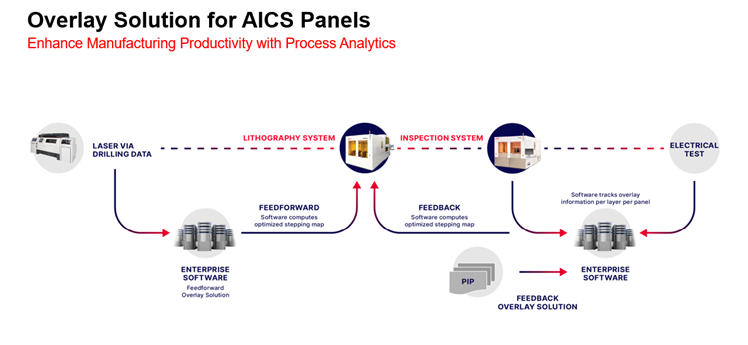

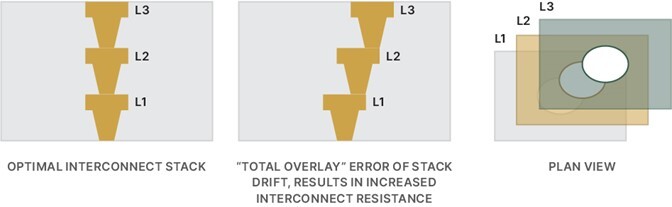

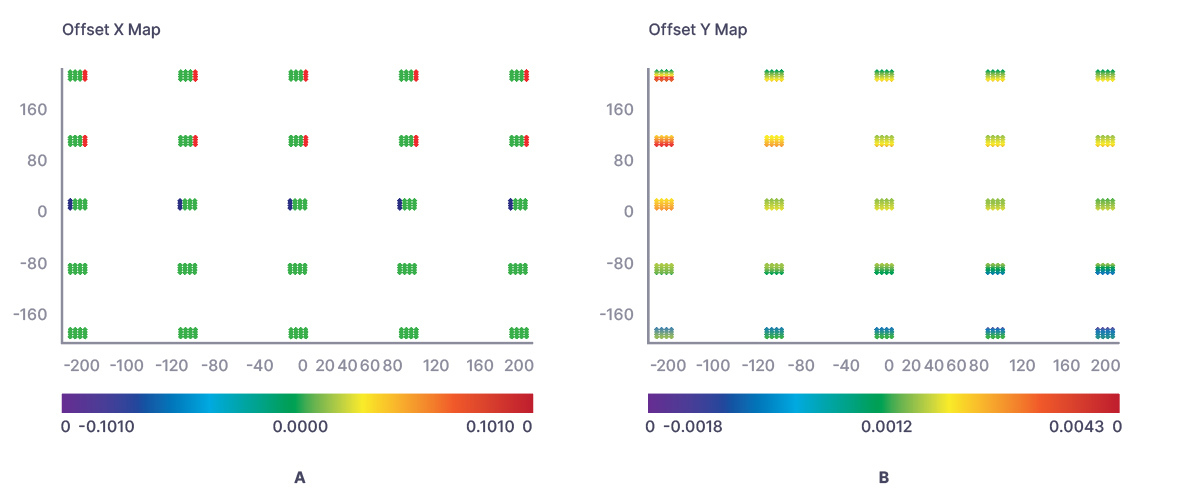

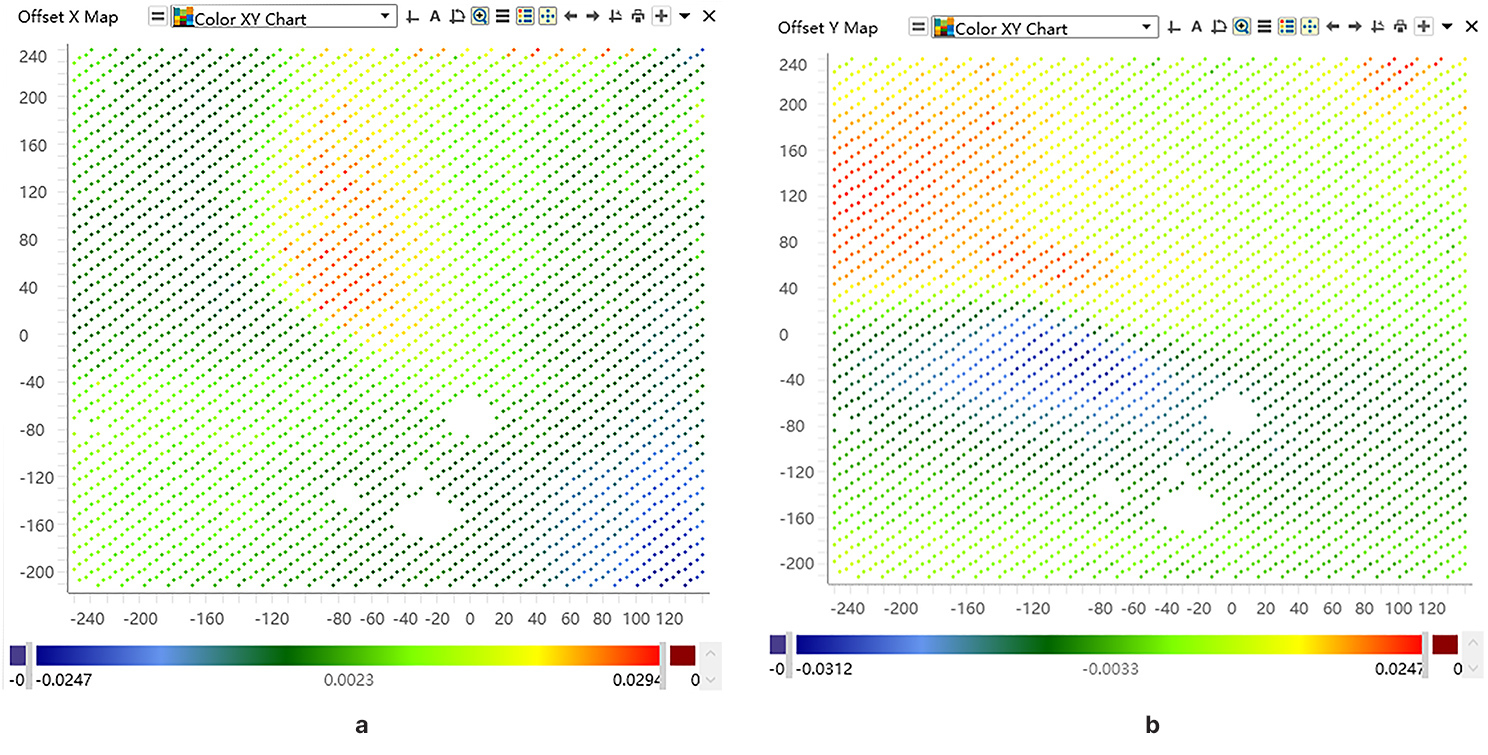

Adaptive Overlay Control

During the processing of organic (CCL) advanced IC substrates (AICS) the substrates become distorted which impacts the overlay of Via to RDL pad structures. To solve this problem, the stepper must adjust the alignment solution to match the previous layer’s distortion by measuring the overlay. Proprietary software provides the user with the ability to adjust each zone of the AICS with independent offsets.

Analysis of Pattern Distortion by Panel Deformation

The growing demand for heterogeneous integration is driven by the 5G market. This includes smartphones, data centers, servers, high-performance computing (HPC), artificial intelligence (AI) and internet of things (IoT) applications. Next generation packaging technologies require tighter overlay to accommodate larger package sizes with fine-pitch chip interconnects on large-format flexible panels.

Do you have a Firefly G3 system question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields