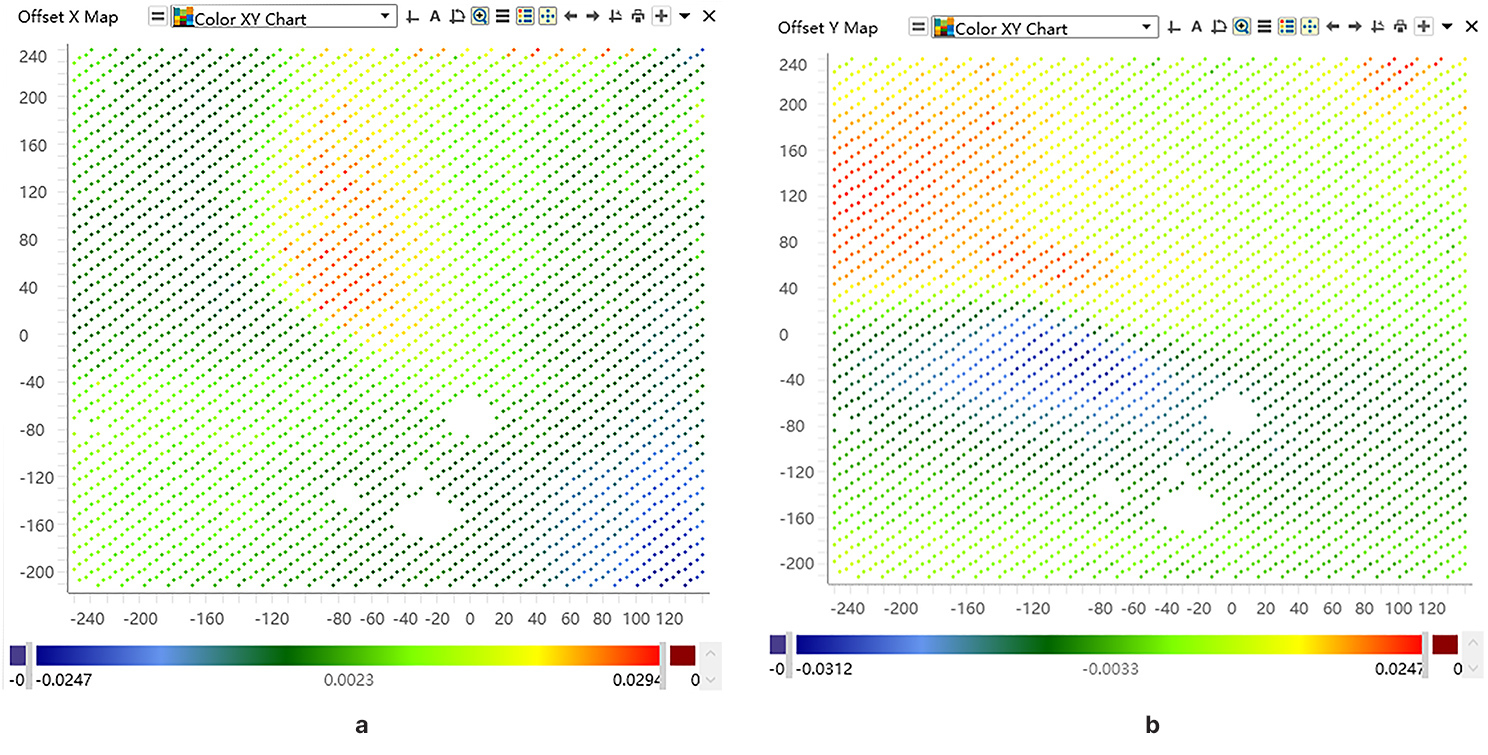

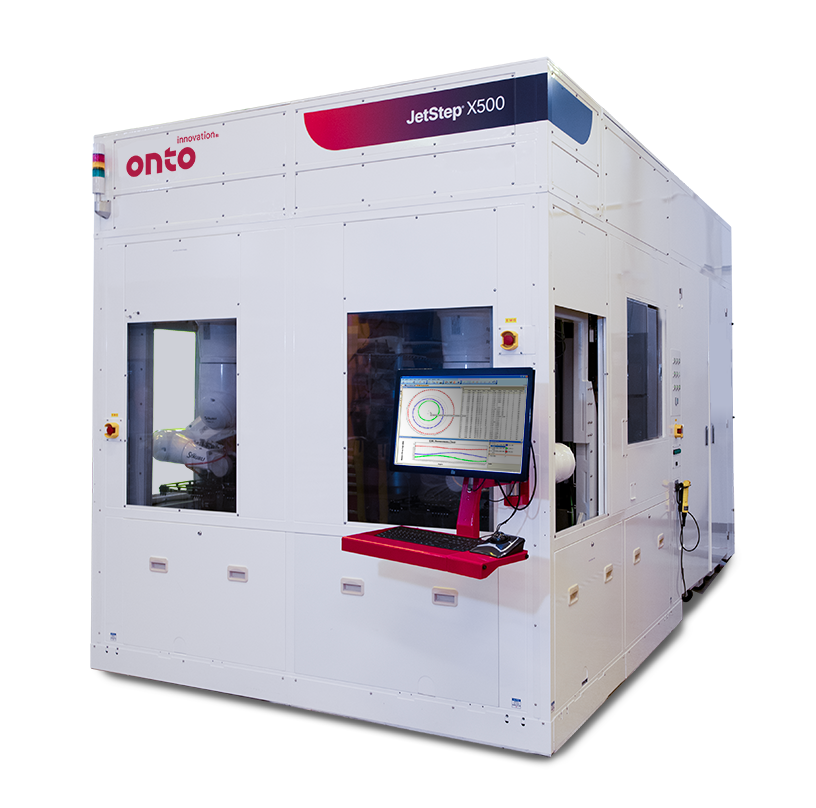

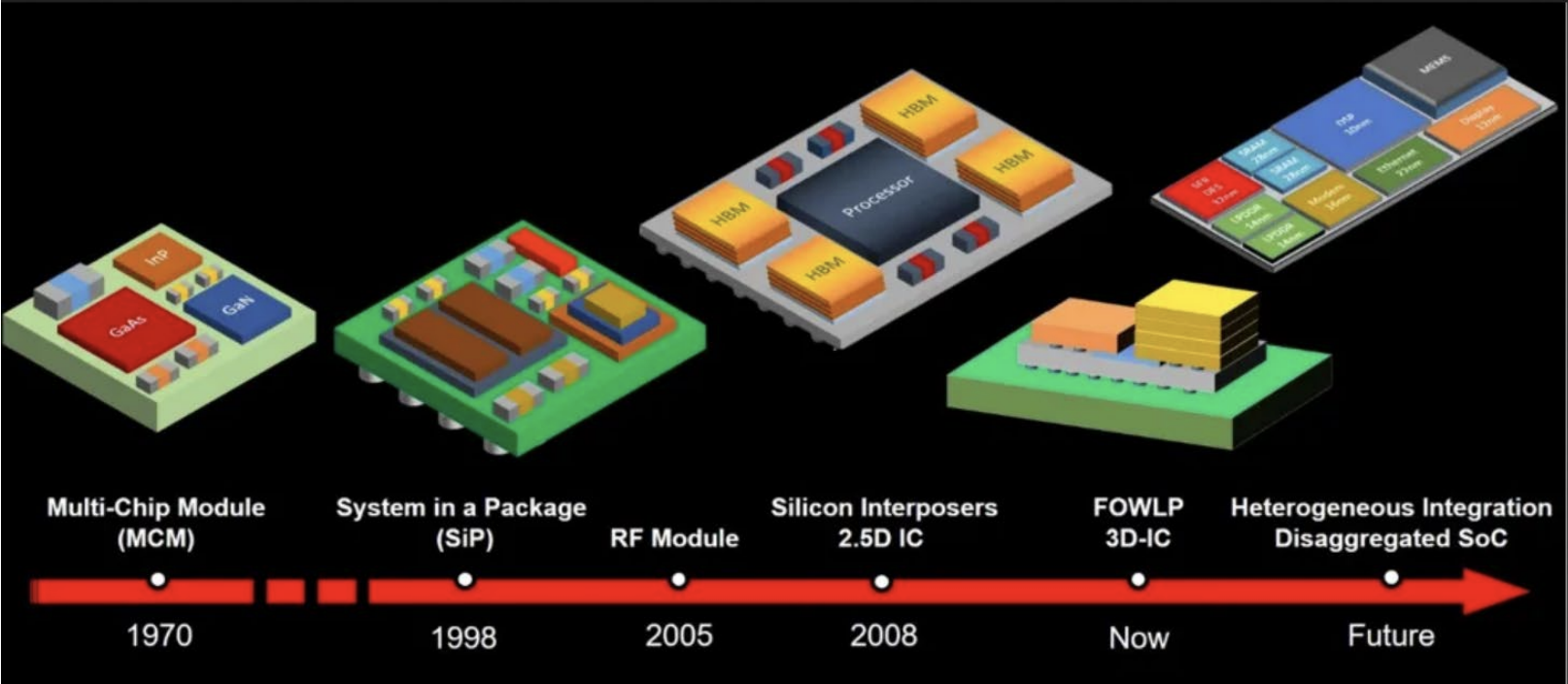

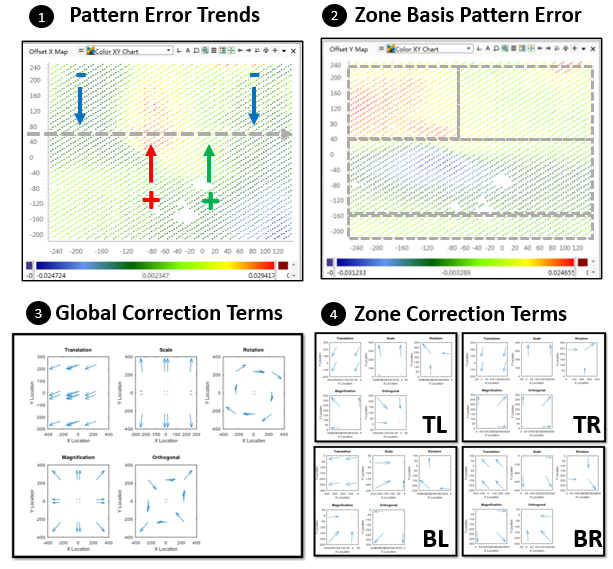

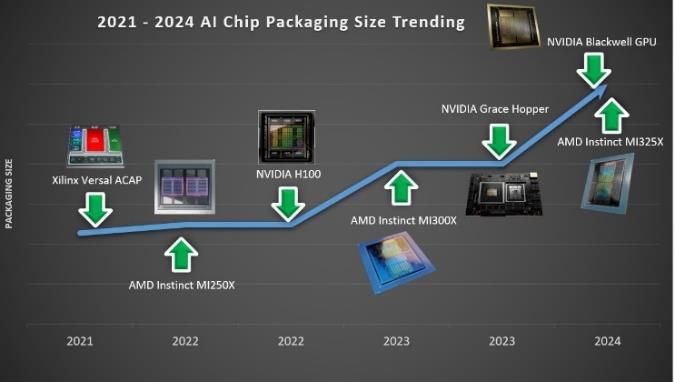

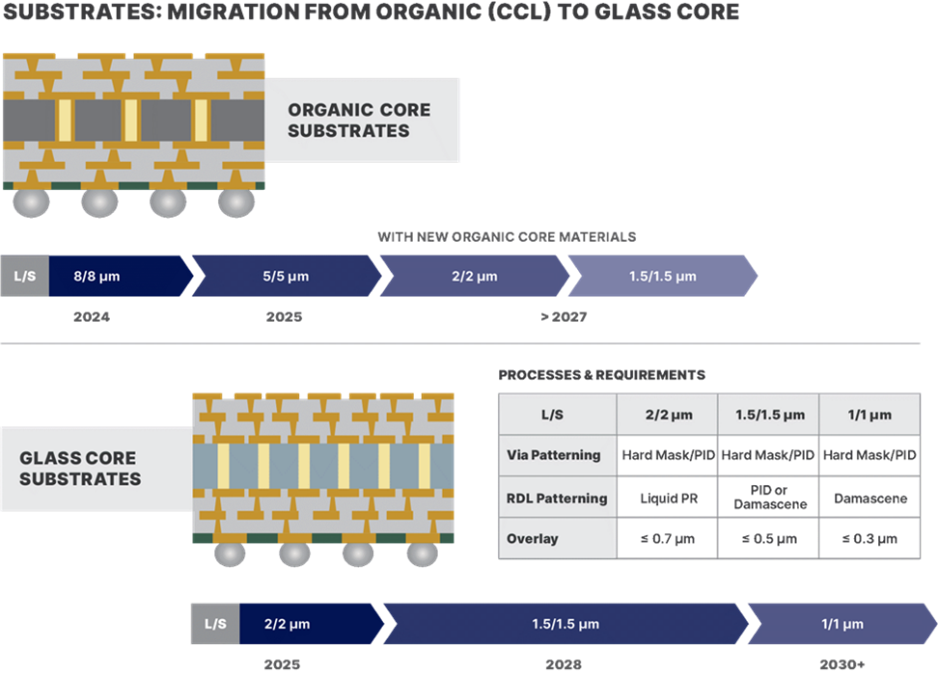

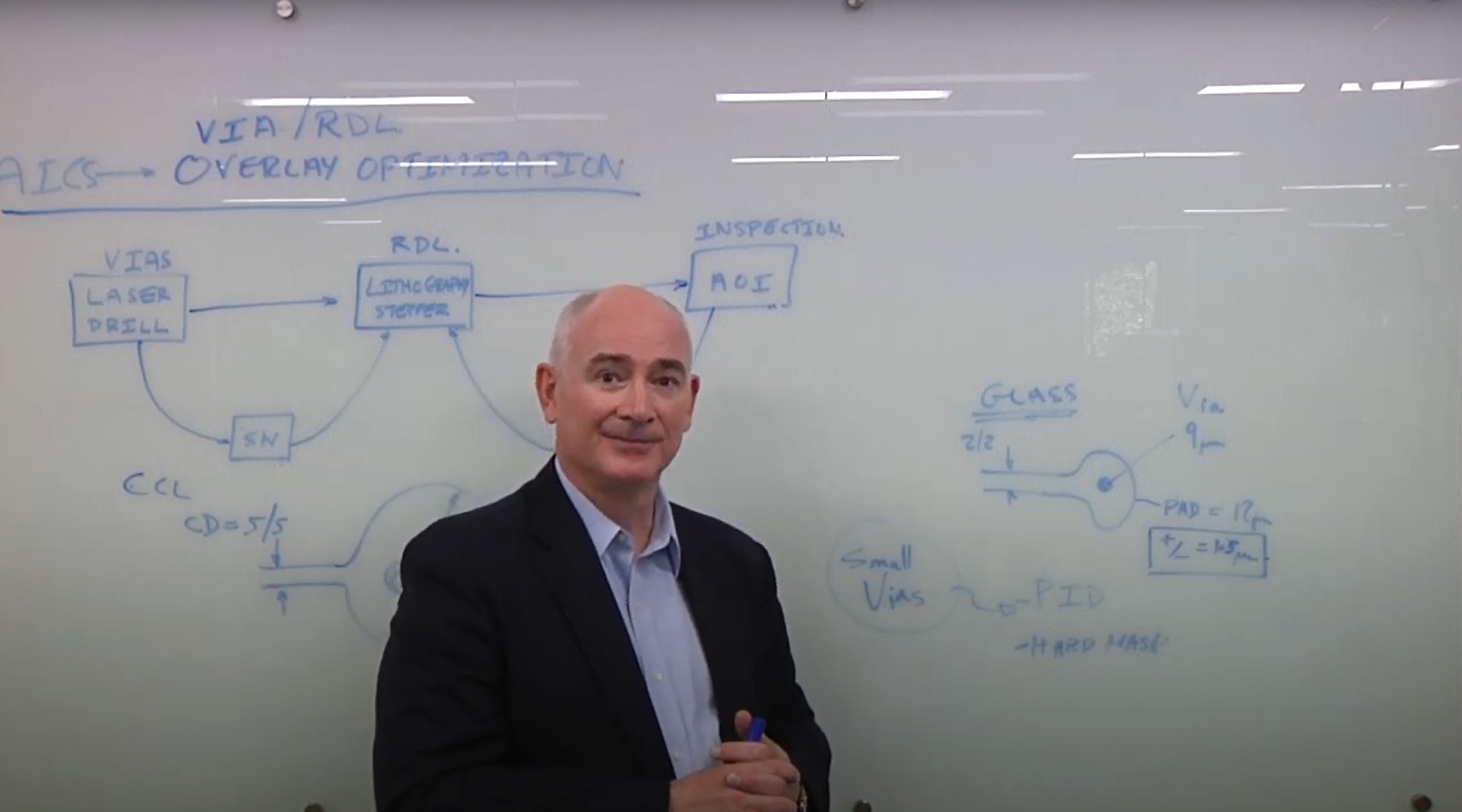

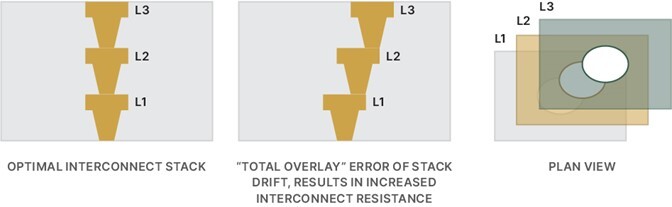

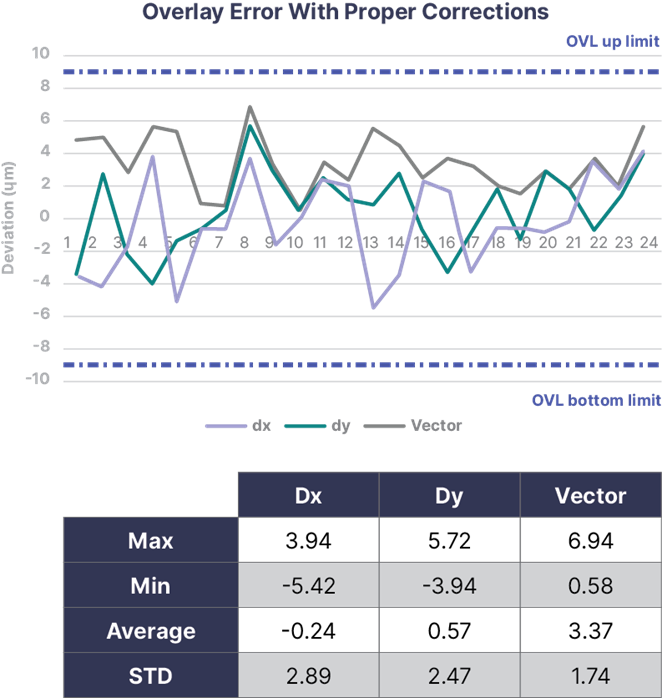

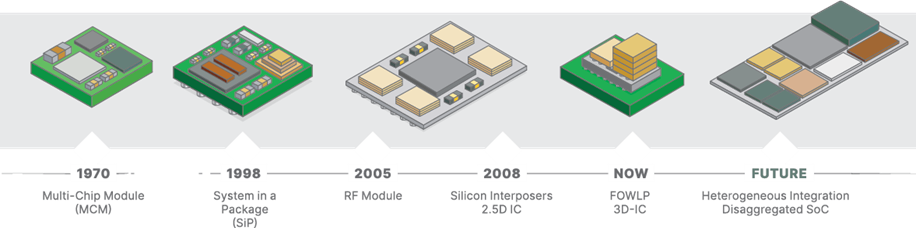

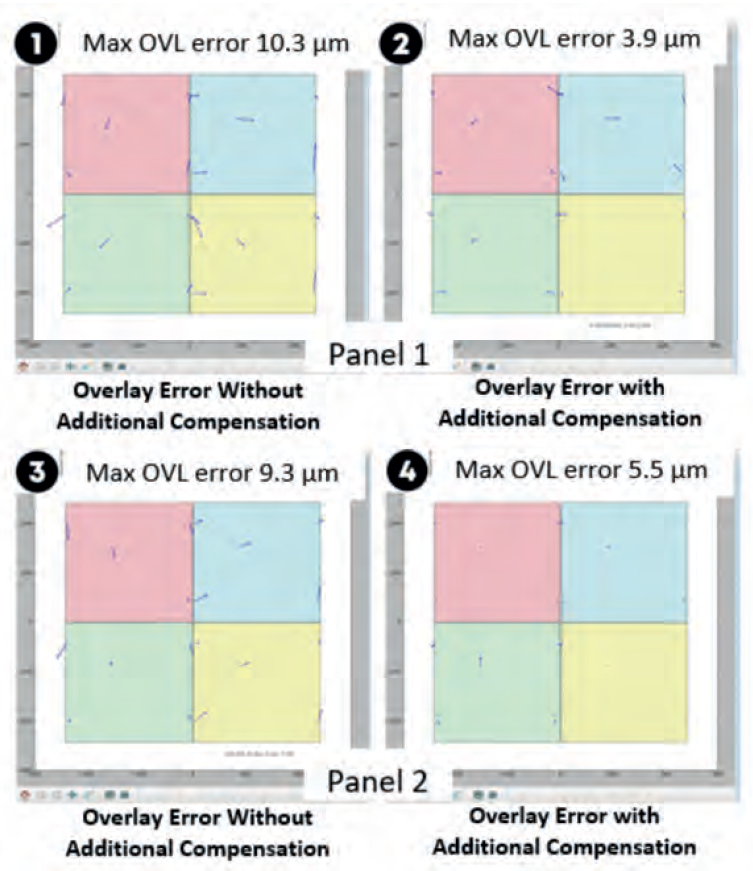

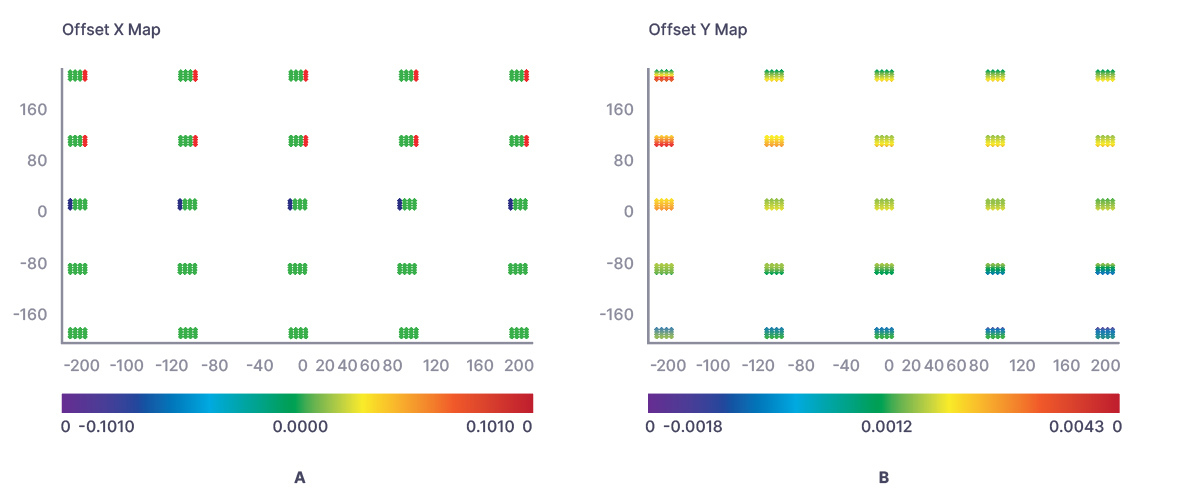

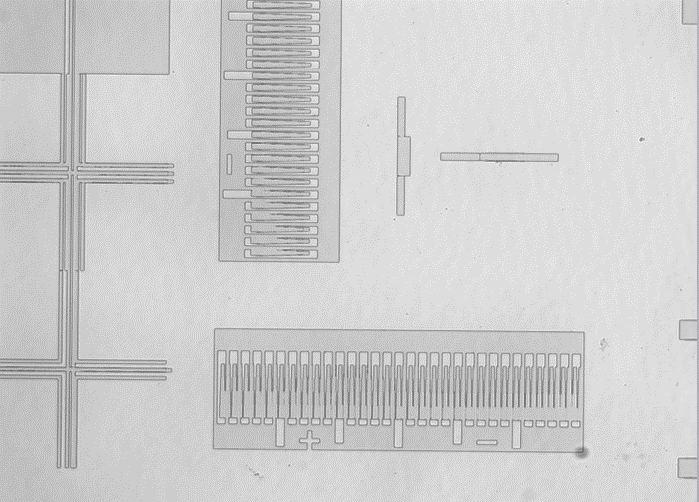

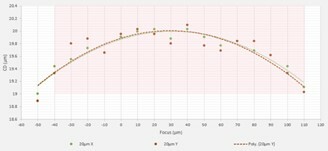

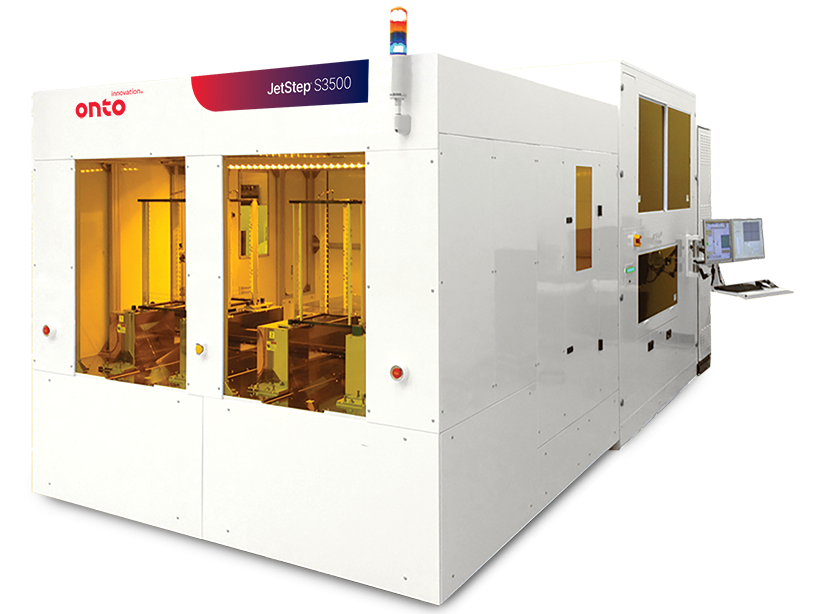

The JetStep X500 panel lithography system is optimized for high volume manufacturing of high-end AICS and other advanced packaging panel applications. As we approach the limits of Moore’s law, the JetStep X500 system addresses the need for extremely large packages integrating multi-node chips, or “chiplets,” enhancing functionality, speed, I/O count and reducing power consumption for server farms, AI, and mobile applications. The JetStep X500 system features the industry’s largest exposure field , fine line RDL resolution with large depth of focus (DOF), excellent overlay accuracy, and automatic magnification compensation with independent x and y magnification adjustment. The JetStep X500 system handles a large range of substrate thicknesses with high levels of warp, offering unique imaging parameter control to compensate for panel distortion. Additionally, it can run highly warped substrates with an edge clamping option and provides real-time autofocus at every exposure site to compensate for challenging topography.