Inspection

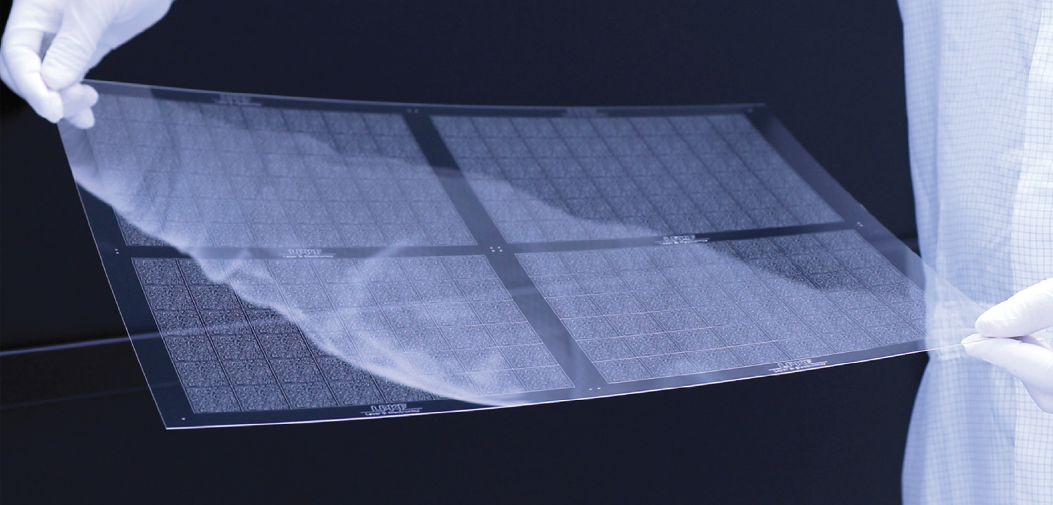

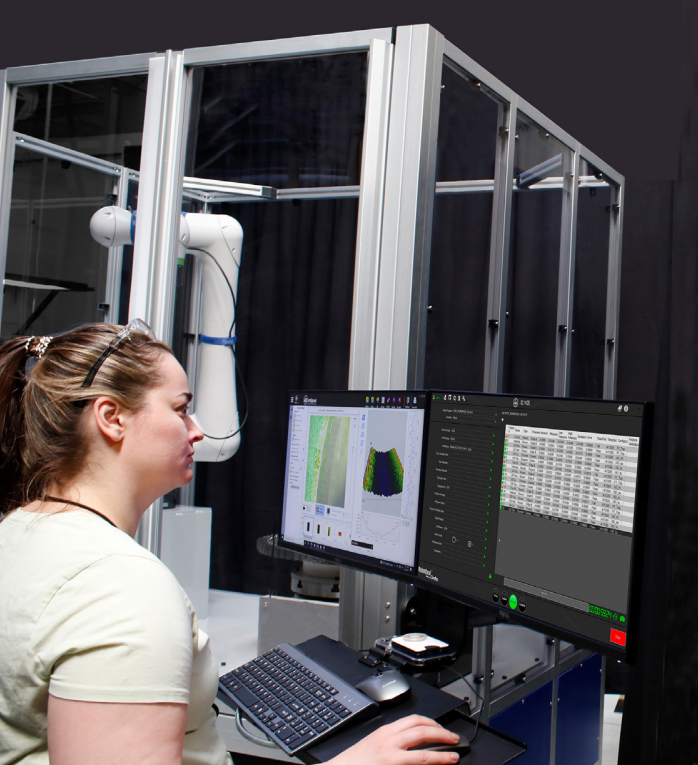

Automated, high-speed defect inspection and actionable data analysis for unpatterned wafer, patterned wafer and panels.

Microelectronics manufacturers partner with Onto Innovation to develop solutions to their most difficult process control challenges. We help improve yield and reliability through high-speed, automated inspection and process control software that transforms defect data into actionable insights.

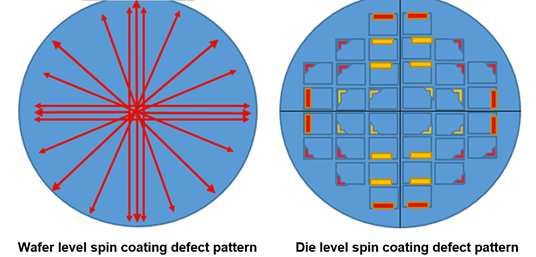

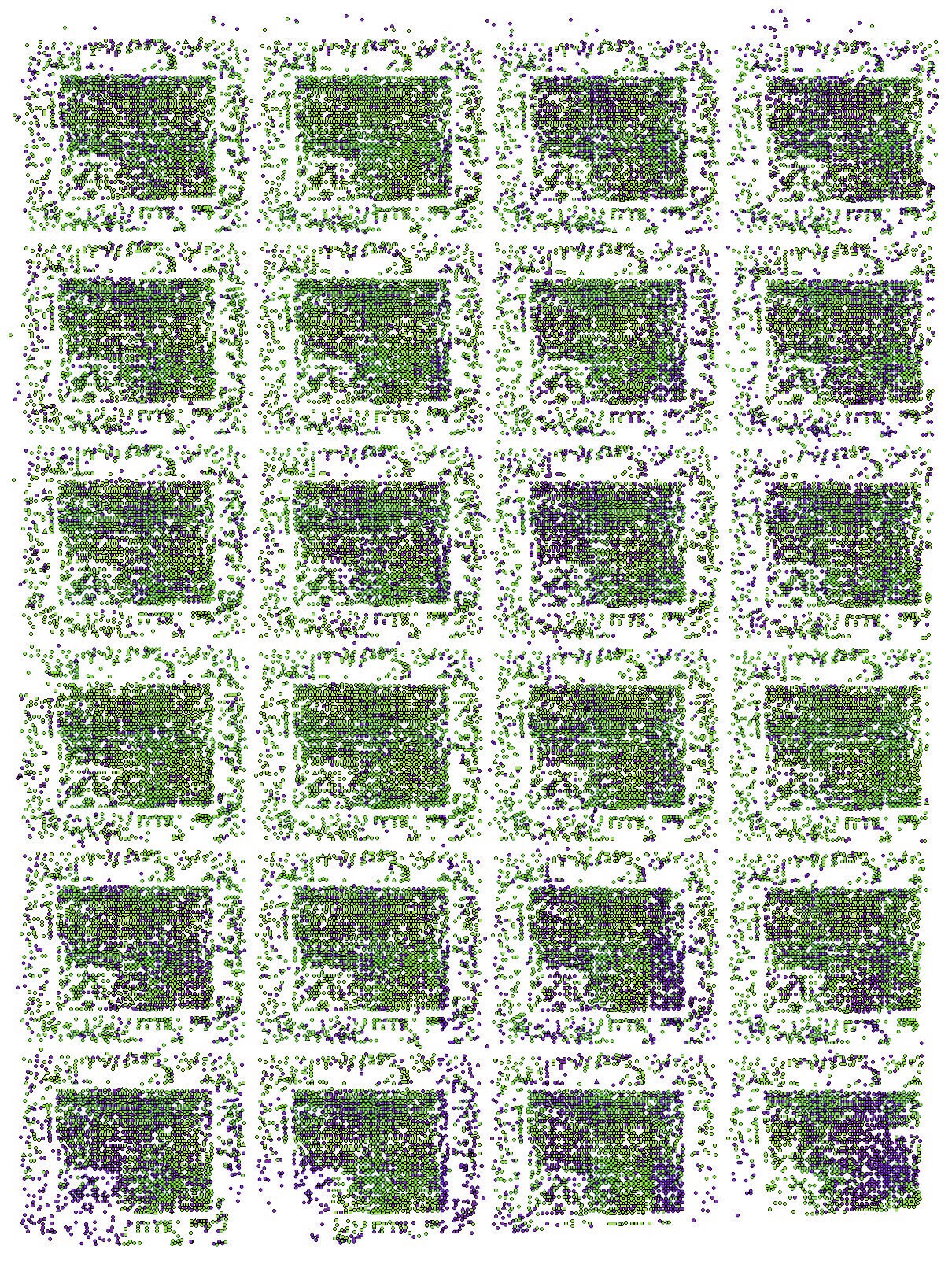

Wafer manufacturers rely on our unpatterned defect inspection solutions to ensure wafer quality, covering frontside, bevel/edge, notch and backside inspection. Likewise, chip makers need tools for macro defect inspection of patterned wafers, panels and stacked die packages to help ensure high yielding processes and an optimized cost of ownership.

From R&D to high volume manufacturing, we’re committed to helping customers realize their full potential.

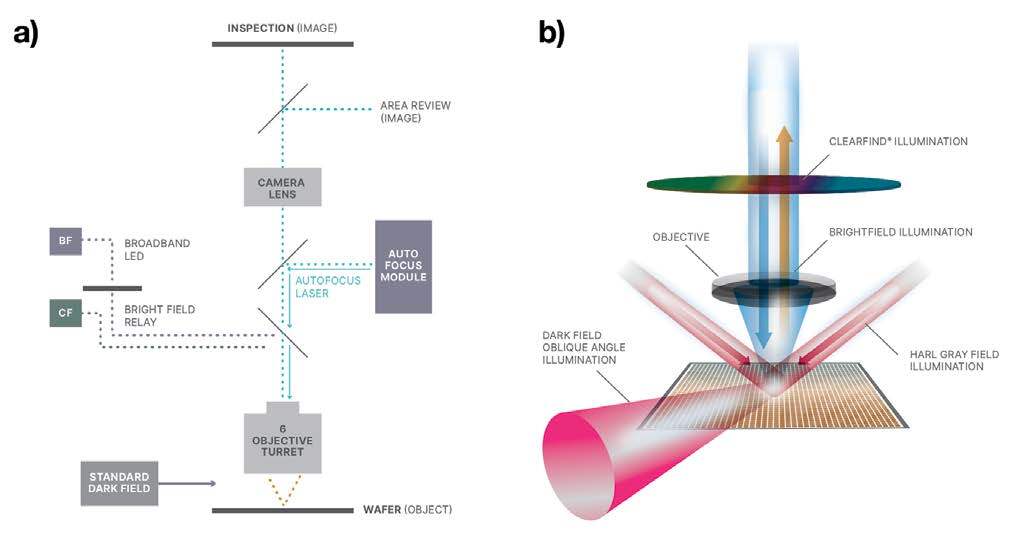

Firefly® G3 System

NovusEdge® G2 System

PrimaScan™ System

Celero™ PL System

EB40™ Module

Inspection Tool Productivity Software

NSX® 330 System

F30™ System

PrimaScan™ P System

PrimaScan™ R&D System

4Di InSpec Automated Measurement System (AMS)

4Di InSpec® Surface Gauge

PrecisionWoRx® VX4 System

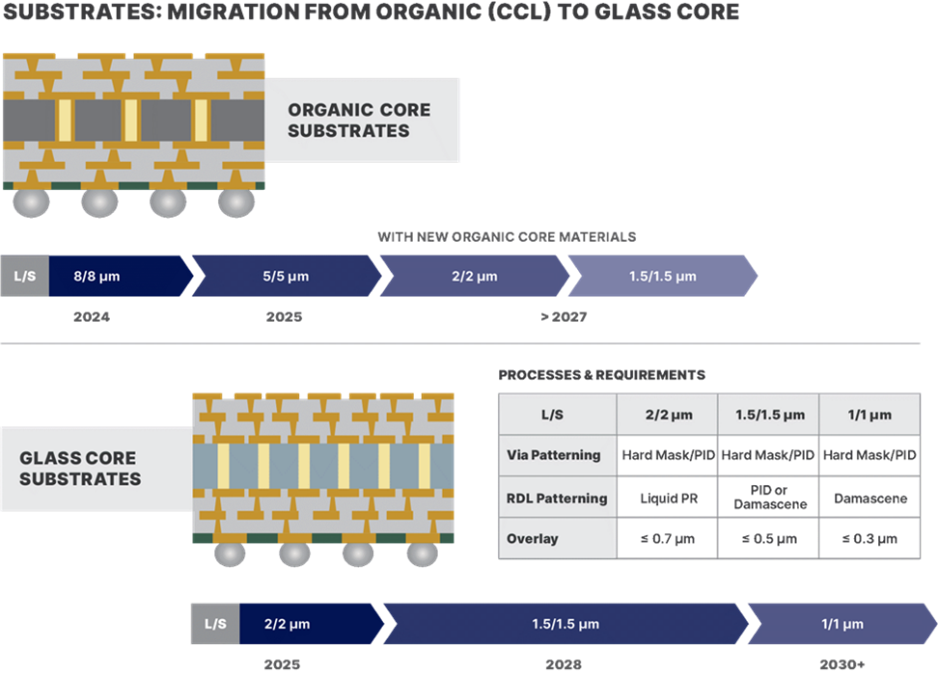

A Clear Advantage: Precision Glass Carrier Inspection for AI and HPC Markets

Through the Glass: Why the Rapid Development of TGV Demands Rigorous Analysis

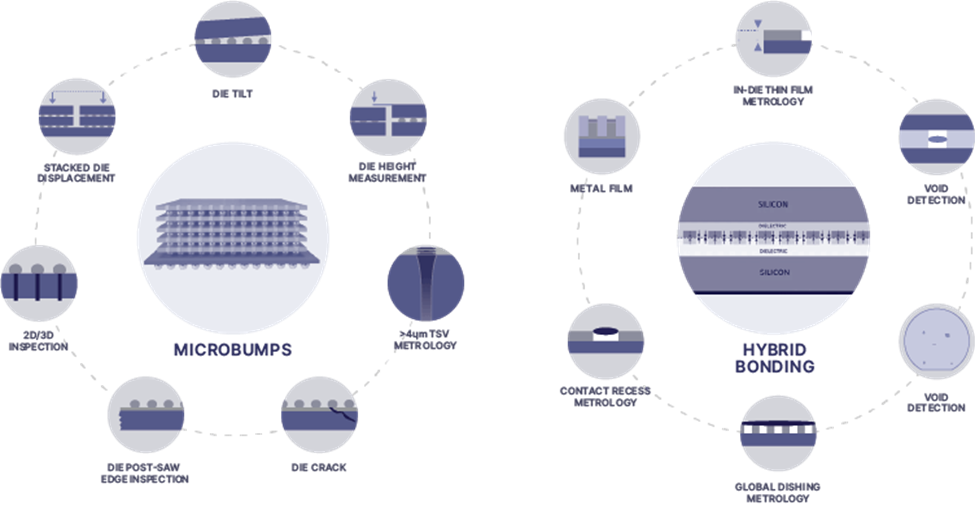

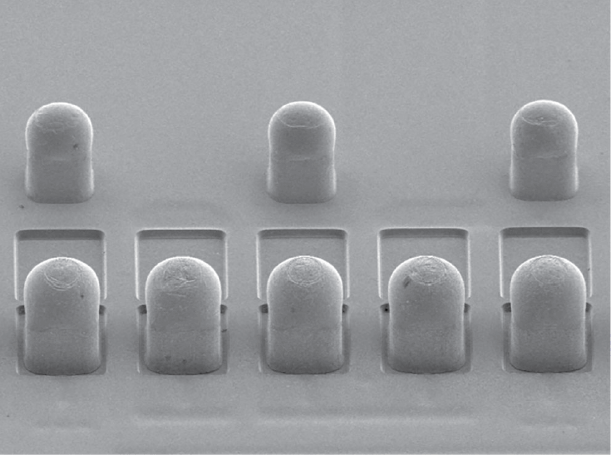

Interconnect Innovations in High Bandwidth Memory, Part 1

Bridging Performance and Yield: The Evolving Role of Interconnect Technologies in HBM

Challenges in Stacking HBM

Enabling In-Line Process Control for Hybrid Bonding Applications

Surface System Enhances Shop-Floor Inspection

The Innovations Driving the Advanced Packaging Roadmap, Part 1

Picking up the Pace of Panel-level Advanced Packaging at Onto Innovation

Achieving Zero Defect Manufacturing Part 3: Prevention Of Defects

Achieving Zero Defect Manufacturing Part 1: Detect & Classify

Using 2D/3D Technology to Overcome Challenges of Large-Area Panel Inspection and Metrology

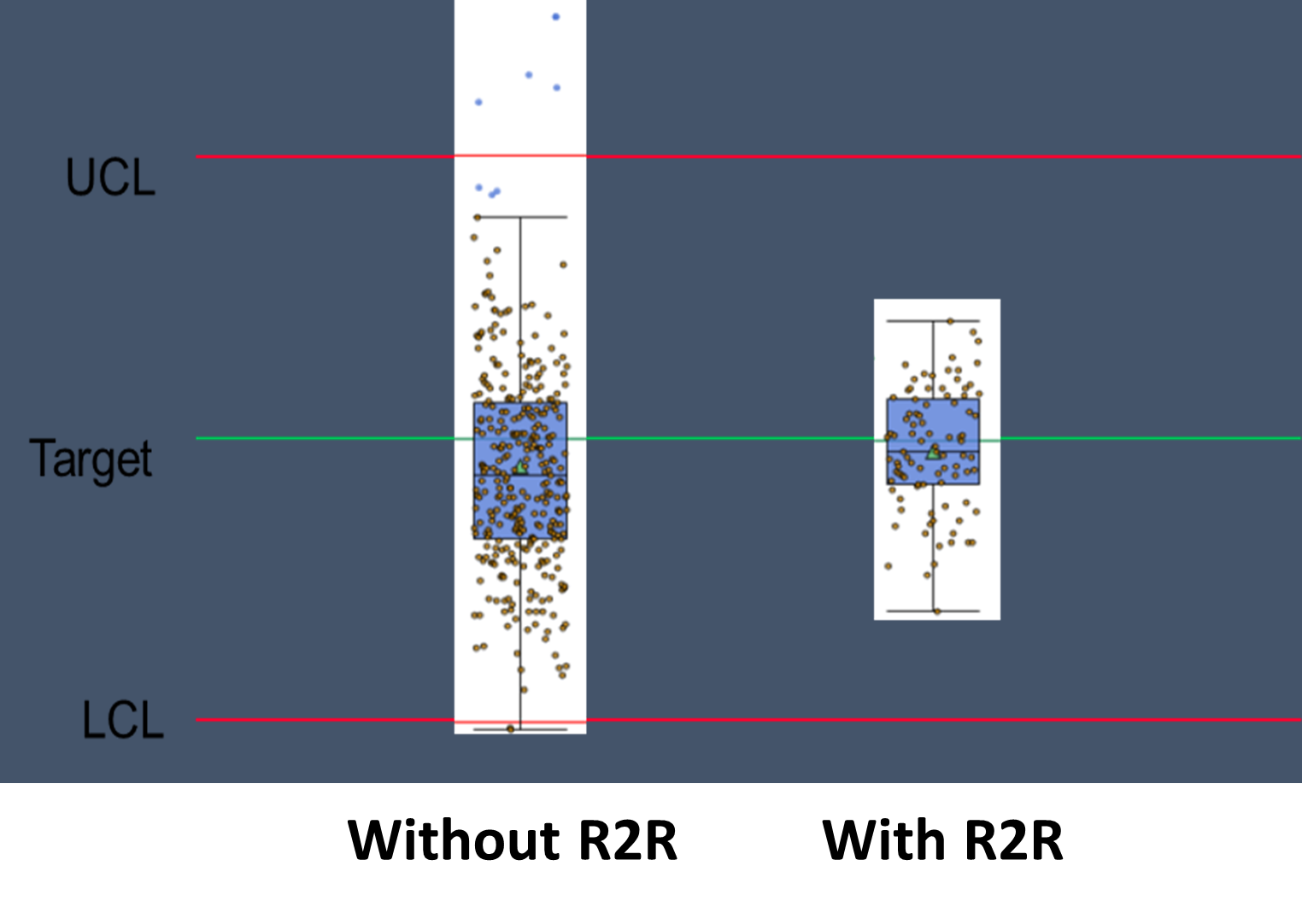

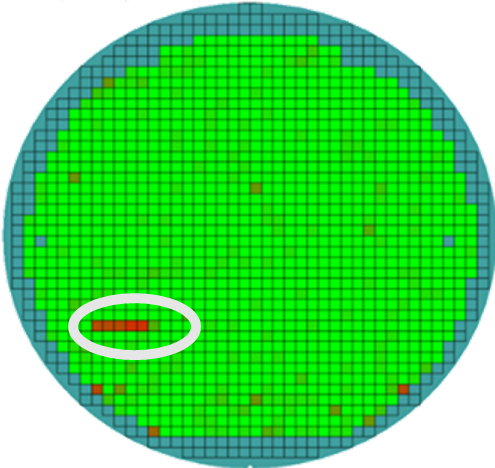

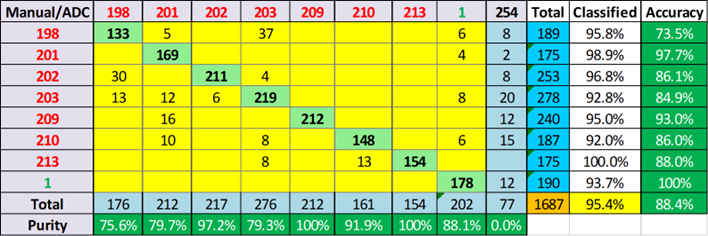

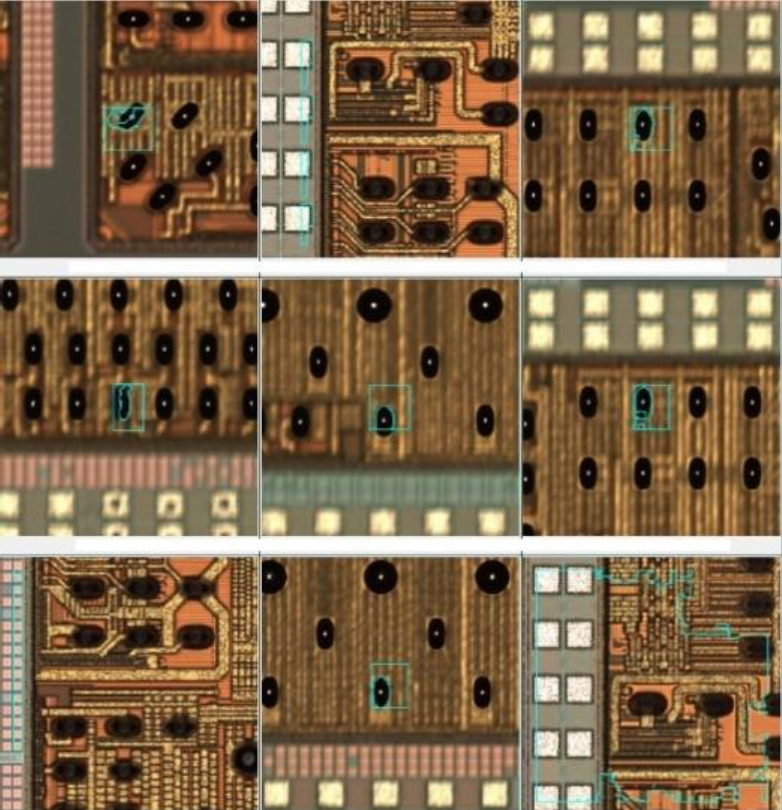

Using Automatic Defect Classification to Reduce the Escape Rate of Defects

How AI is Helping Optimize AI Chip Production

High-Throughput, High Resolution Defect and Feature Inspection Solution

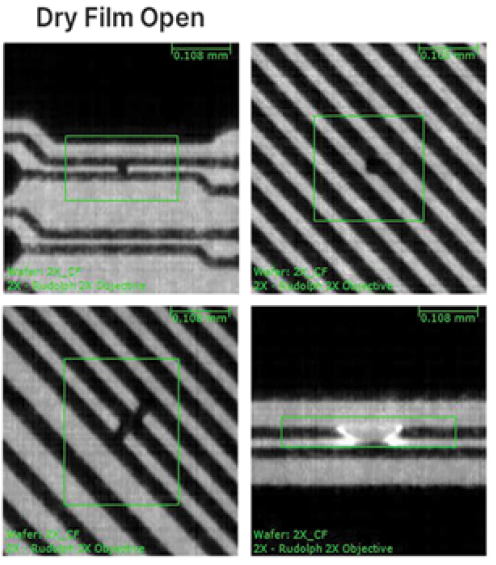

Using Deep Learning ADC for Defect Classification for Automatic Defect Inspection

Driving Down Inspection Time for Critical Aviation and Aerospace Components

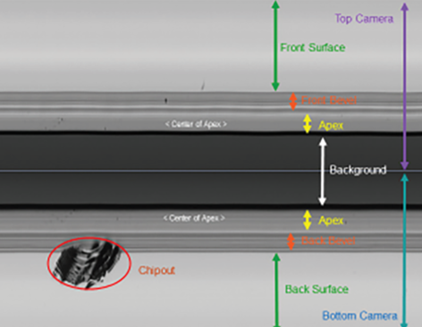

A Bare Wafer Mystery: Inspecting for Back, Edge and Notch Defects in Advanced Nodes

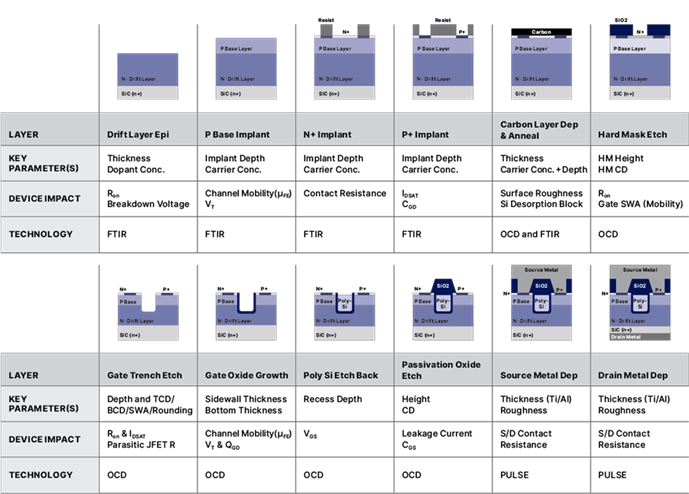

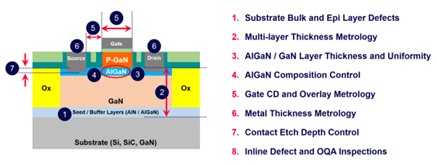

Addressing Trench Structures and Larger Wafers for Power Devices

Illumination Inspection Technology for Defect Detection on Advanced IC Substrates

The Age of Hybrid Bonding: Where We Are and Where We’re Going

A Star is Born: Gallium nitride and the coming age of compound semiconductors

Hunting For Macro Defects: The Importance Of Bare Wafer Inspection

Center Stage: The time for hybrid bonding has arrived

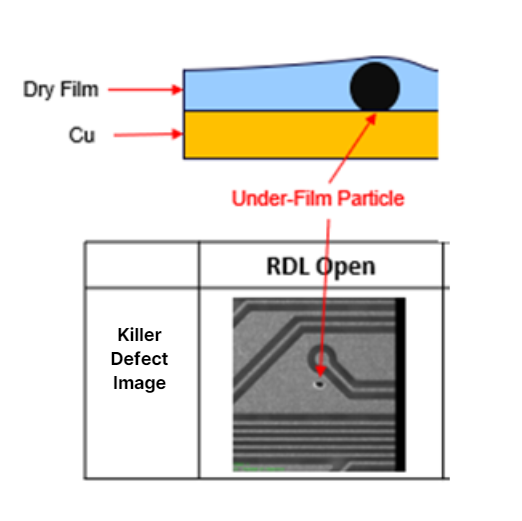

Addressing The ABF Substrate Shortage With In-Line Monitoring

In The Spotlight: What Is Responsible For The Surging Demand For CIS?

Understanding Optical Inspection For CIS

Revealing Invisible Defects on Large 600mm Panels

Do you have an inspection question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields