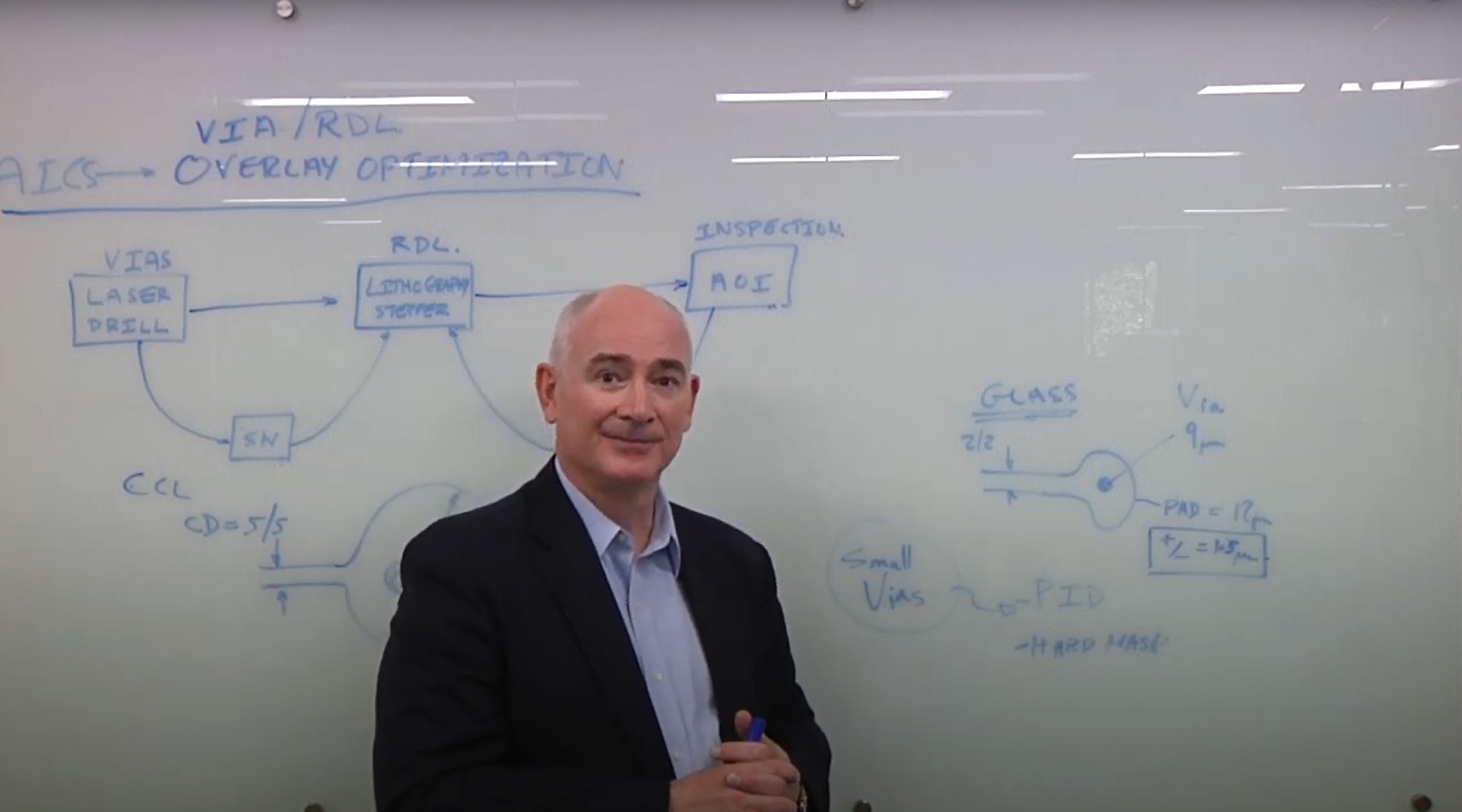

Lithography

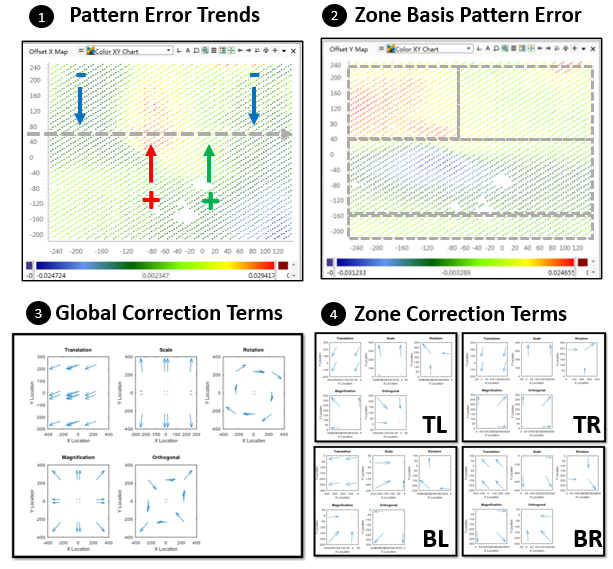

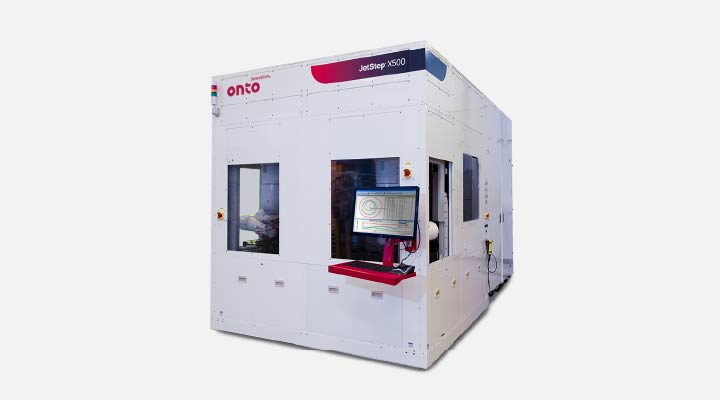

Advanced packaging steppers designed to tackle manufacturing challenges, maximizing throughput while ensuring high resolution and precise overlay.

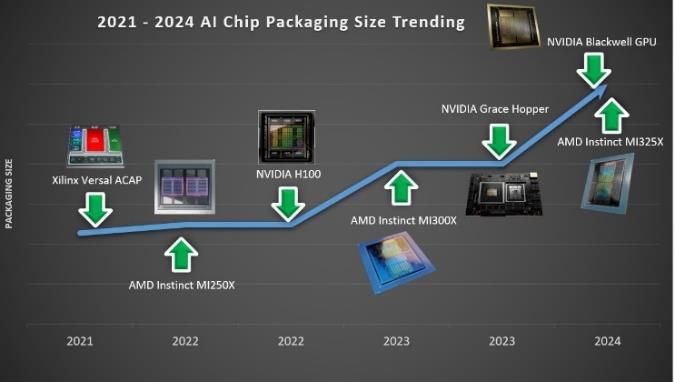

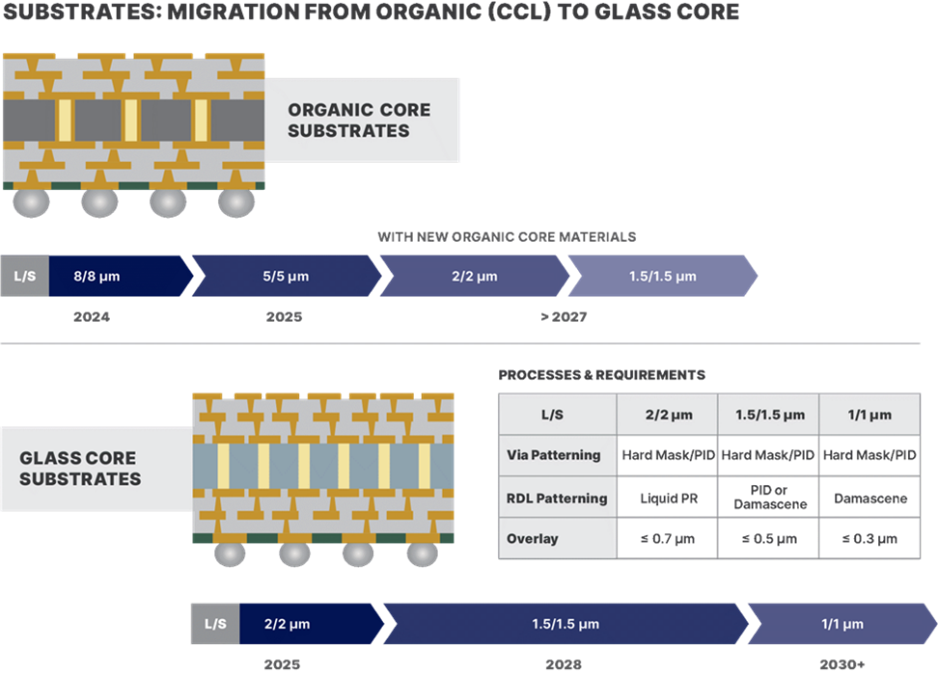

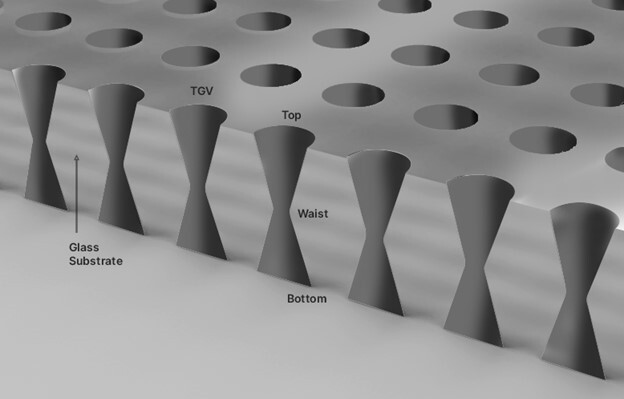

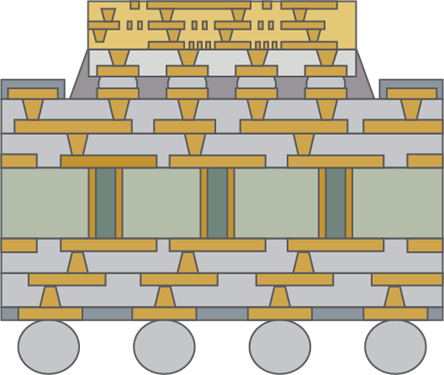

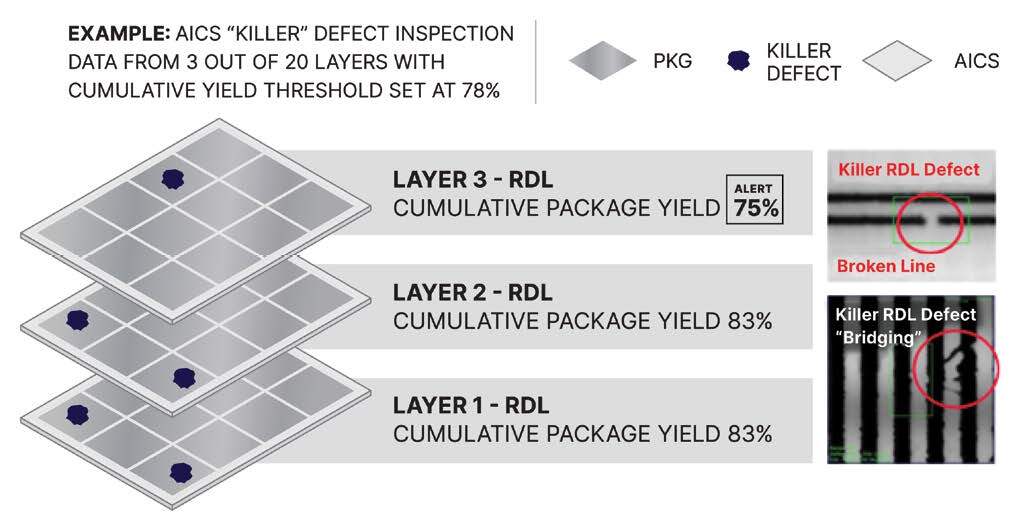

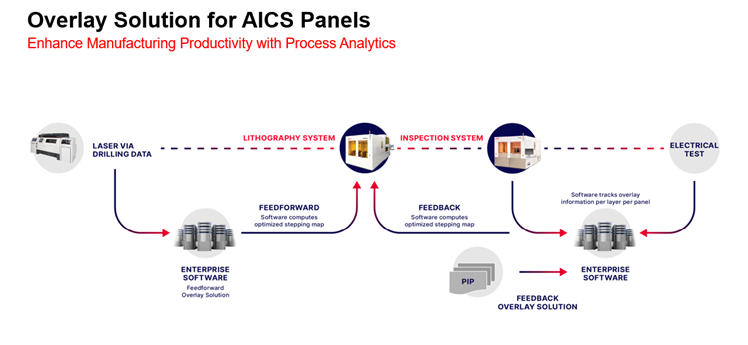

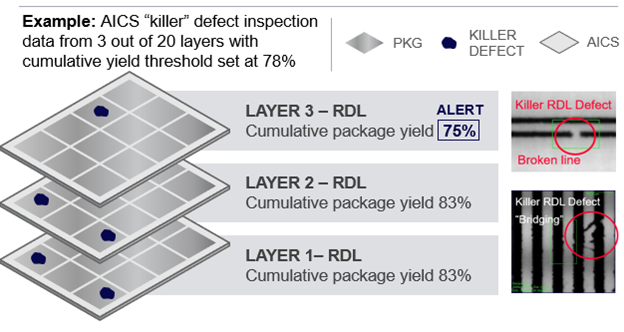

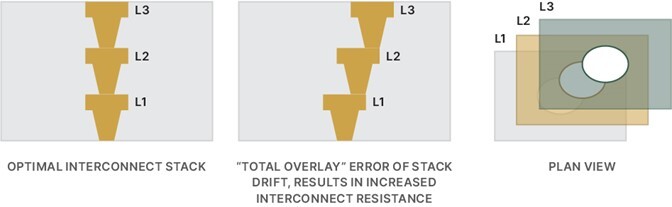

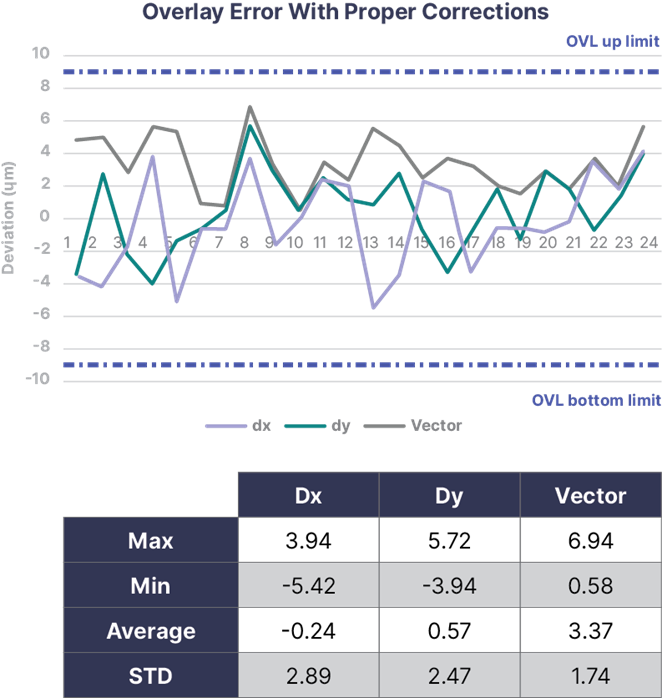

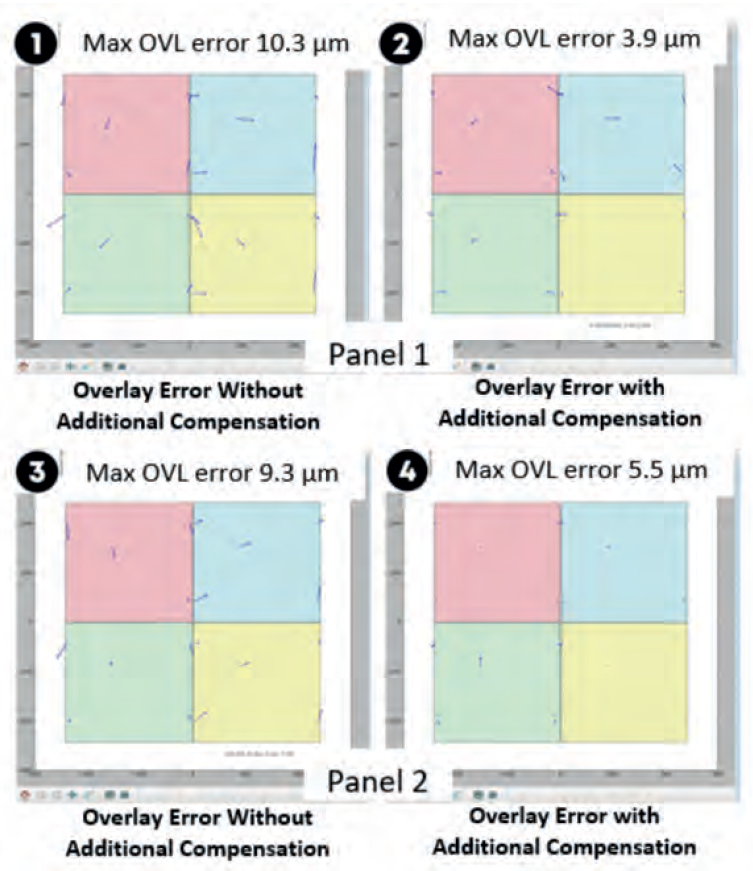

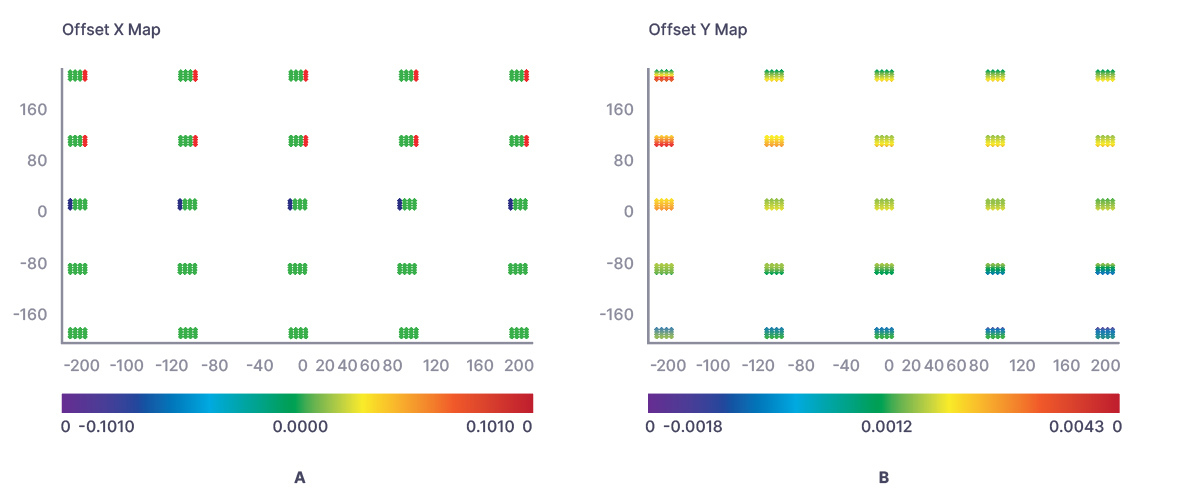

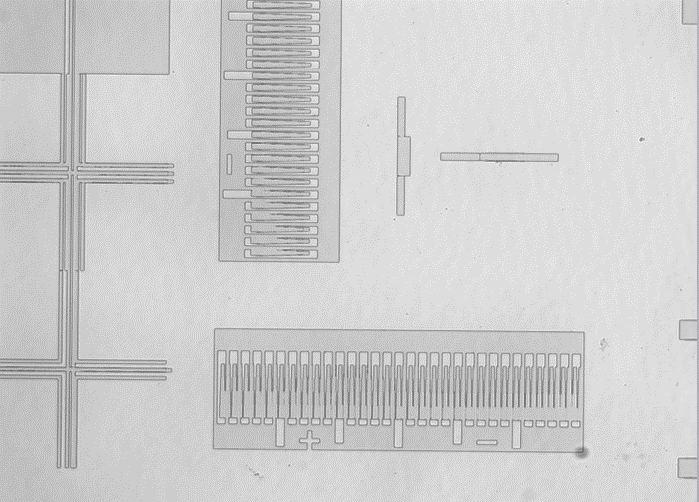

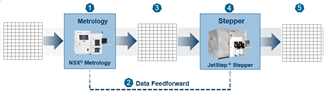

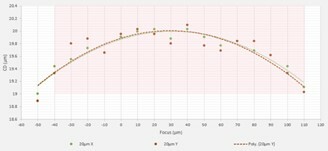

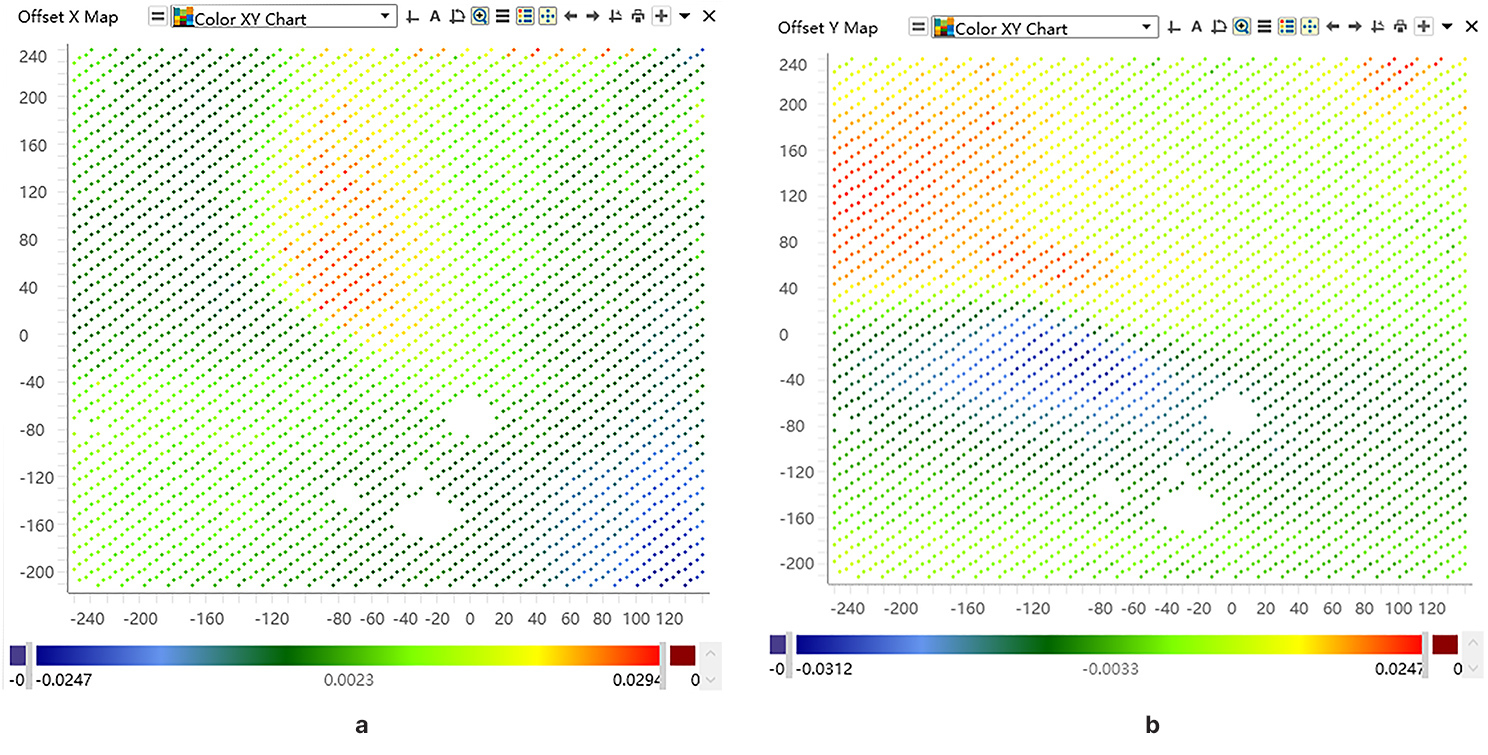

The future of AI technology is here, with new high performance computing designs and process architectures that support larger packages and require smaller, denser interconnects. As the advanced packaging roadmap evolves, the demand for larger package sizes grows, necessitating substrates that support high volume manufacturing. Enter, the panel. A panel substrate, whether organic or glass advanced IC substrates (AICS) or fan-out panel level packaging (FOPLP) with epoxy mold compound, offers approximately five times more area than a traditional 300mm wafer. High density interconnects are at the core of advanced packaging and high-resolution lithography at high throughput is essential to help the industry realize the advanced packaging roadmap. Our steppers are designed to tackle these manufacturing challenges, maximizing throughput while ensuring high resolution and precise overlay.

Do you have a lithography question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields