Reducing Rework In CMP: An Enhanced Machine Learning-Based Hybrid Metrology Approach

The semiconductor industry is constantly marching toward thinner films and complex geometries with smaller dimensions, as well as newer materials. The number of chemical mechanical planarization (CMP) steps has increased and, with it, a greater need for within-wafer uniformity and wafer-to-wafer control of the thin film layers.

Process engineers have typically adopted over-polishing and re-working as part of the standard operating procedure to reach the desired end point and required film uniformity on the wafers. This is because the current generation of integrated metrology toolsets are based on relatively simple optical techniques, such as reflectometry, and do not have the inherent high resolution offered by off-line techniques, such as ellipsometry, which are technically complicated and cost prohibitive to implement as integrated solutions on process tools.

When it comes to thin film residuals, the current steps in the CMP process — with both over-polish and rework steps playing prominent roles — are inefficient and result in lower yields.

The next generation of CMP tools from leading suppliers are targeting a 100% increase over current throughput, going from 80 to 100 wafers per hour to more than 200 wafers per hour. In order to achieve the expected increase in throughput, the time currently being spent on offline feedback and rework is simply not feasible as a part of a process control strategy.

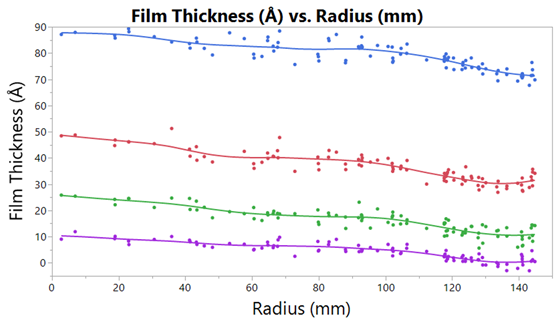

If the true potential of these next-gen CMP tools is to be reached, these CMP tools must be installed with integrated metrology capable of measuring extremely thin films and accurately reporting the end point, thereby eliminating the need for offline metrology. With this requirement, integrated metrology modules will need additional input and data processing capability to measure sub-50Å residual films in a CMP environment.

A recent internal study between Onto Innovation and Micron indicates that a hybrid metrology approach can be effective in improving the measurement accuracy of thinner films. This approach combines measurements from different steps in the process and then uses that information to enhance the data analysis of the integrated metrology tool via machine learning. Such an approach provides accurate film thickness discrimination and enables the proper end point in CMP. This reduces the need for over-polishing and significantly reduces the rework rate.