Element™ S System

The Element S system offers a unique combination of transmission and reflection-based technology, making it a valuable tool for dielectric monitoring.

Product Overview

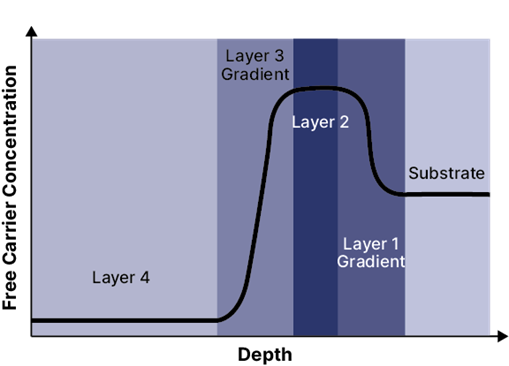

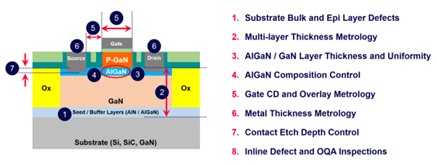

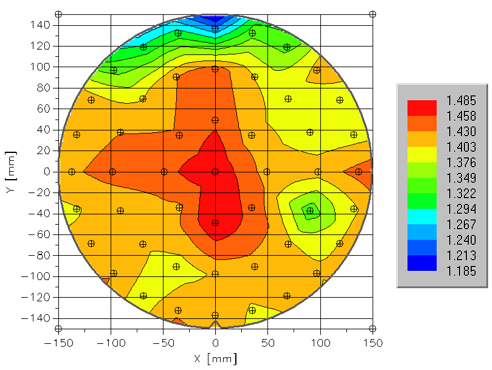

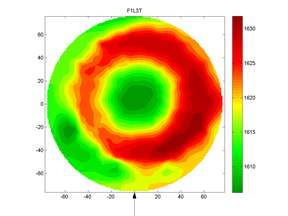

The Element S system is designed for the specialty market, specifically the smaller 100mm to 200mm wafer sizes used in the rapidly growing Si/SiC/GaN power device market. Building on the success of the Element Fourier transform infrared (FTIR) system, the Element S system can accurately measure thickness and free carrier concentrations in epitaxial layers up to five layers. This capability is essential for characterizing the thick epitaxial films required for next generation SiC power devices, which need thick epi layers for higher standoff voltage.

With its small spot size, the Element S system can conduct measurements up to the very edge of the wafer, maximizing die yield and enhancing productivity as power device customers transition to 200mm wafers. With improved sensitivity, an advanced multi-layer epi algorithm, and leading-edge multiple IR peak modeling, the Element S system provides critical and versatile capabilities for wafer and device makers in epi and film composition monitoring.

Applications

- Multi layer Epi layer, transition zone thickness and substrate concentration

- Power device EPI and buffer layer

- BPSG, FSG, SiN, HSQ, SiON, SiCN, SiOC

- Multiple IR peak metrics

- Interstitial oxygen and substitutional carbon

- Oxygen dose and Oxygen precipitate

Featured Markets

Do you have an Element S system question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields

Echo™ System

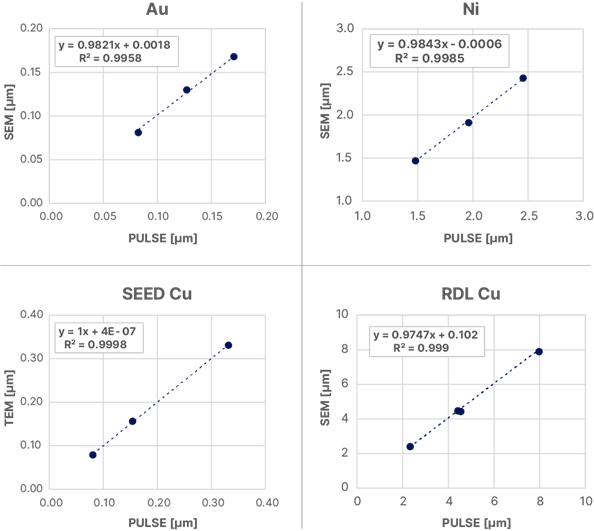

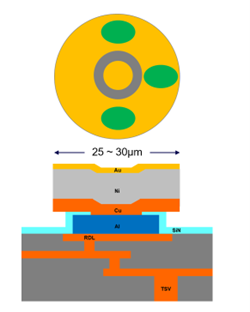

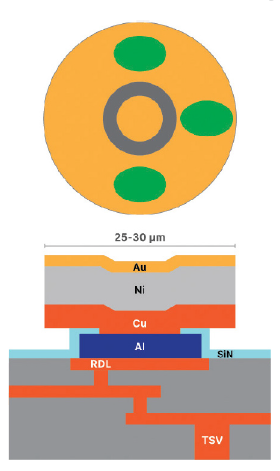

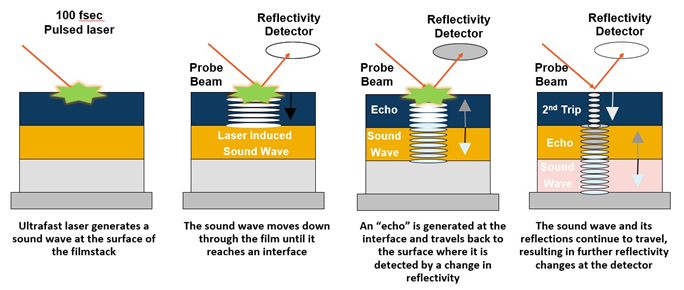

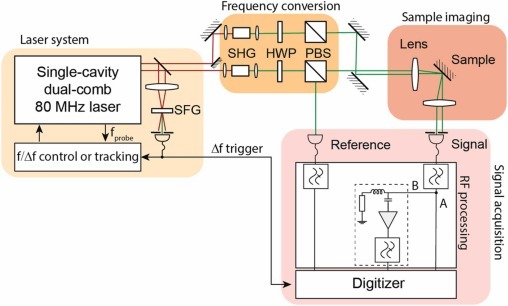

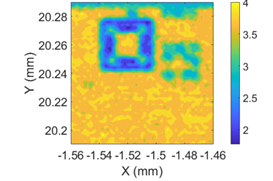

The Echo system utilizes picosecond ultrasonics to provide accurate, in-line, on-product metrology and materials characterization for semiconductor processes requiring metal thickness metrology, implant monitoring or thermal conductivity characterization on product wafers.

Product Overview

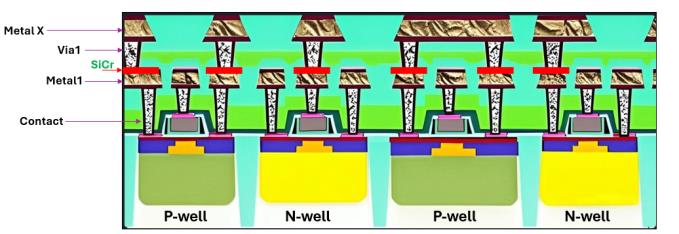

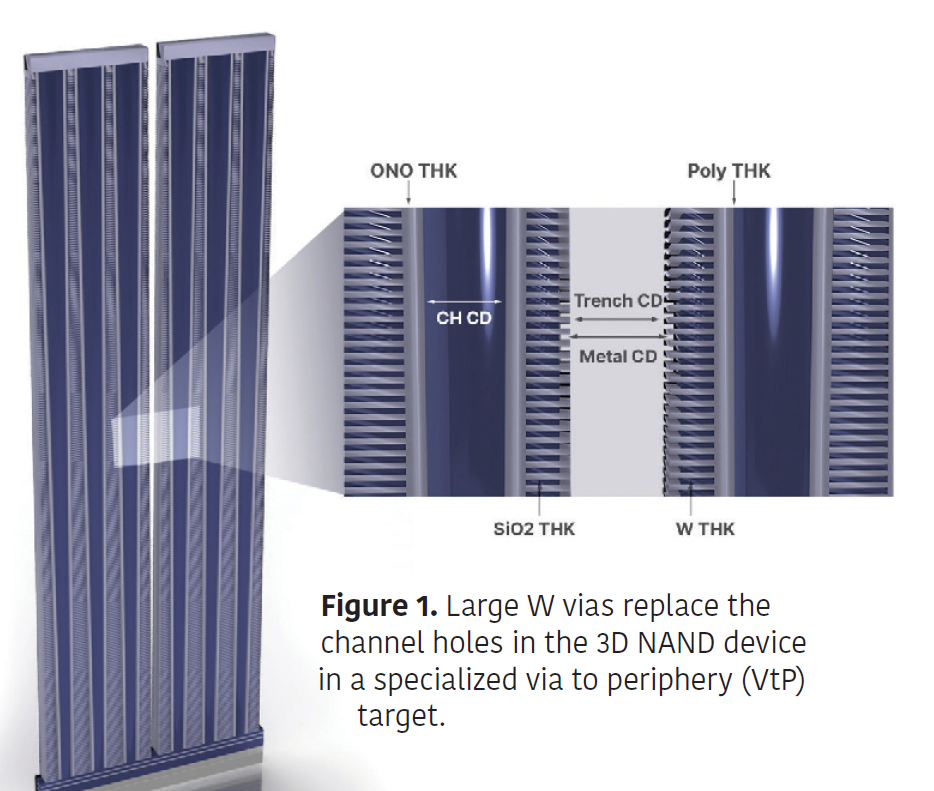

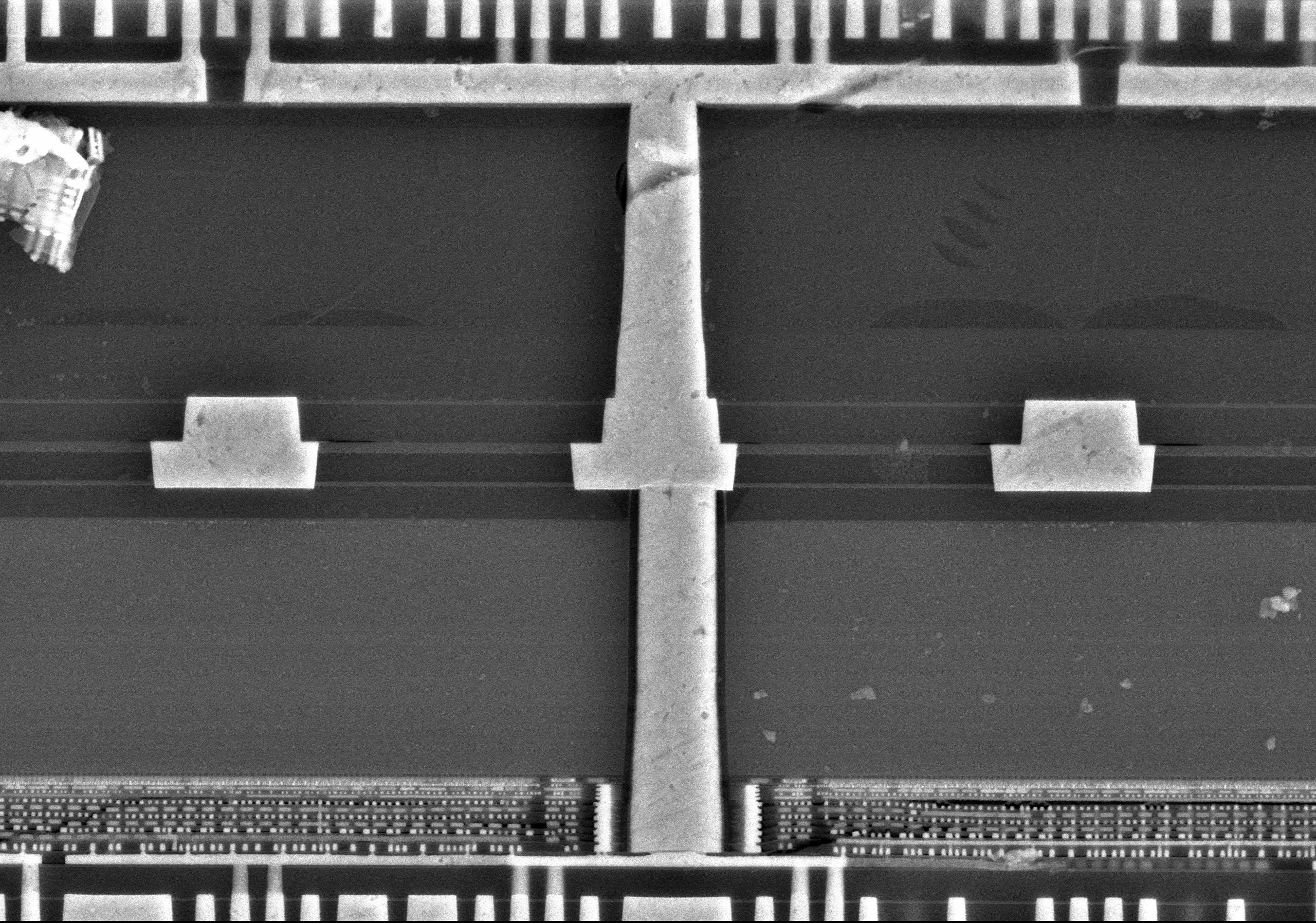

The Echo system is a comprehensive in-line metal film metrology tool designed for single and multi-layer metal film measurements in leading-edge logic, memory, advanced packaging and specialty semiconductor devices. Its innovative optics design extends the dynamic range for film thickness measurement from 50Å to 35µm on a single platform and offers extendibility to measure high aspect ratio advanced 3D NAND structures. The Expert Applications System (EASy™) software provides flexibility for developing user-defined algorithms to model complex multi-layer stacks.

The Echo system’s capabilities have been extended to include materials characterization. In addition to measuring the Young’s Modulus of low-k dielectric films in BEOL and amorphous carbon hard masks in 3D NAND, the Echo system includes proprietary electronics and algorithms for implant monitoring and thermal conductivity characterization. Its small spot size, combined with rapid measurements, enables full wafer mapping capabilities with 0.5mm edge exclusion, improving time to yield.

Applications

- Gate metals, plug/contact, barrier/seed layers, top metal

- RF electrode/IDT

- Advanced packaging UBM, RDL

- 3D NAND Hard mask

- MEMS Poly/Ge

- Low-k, ultra low-k film modulus, implant, thermal conductivity

Do you have an Echo system question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields

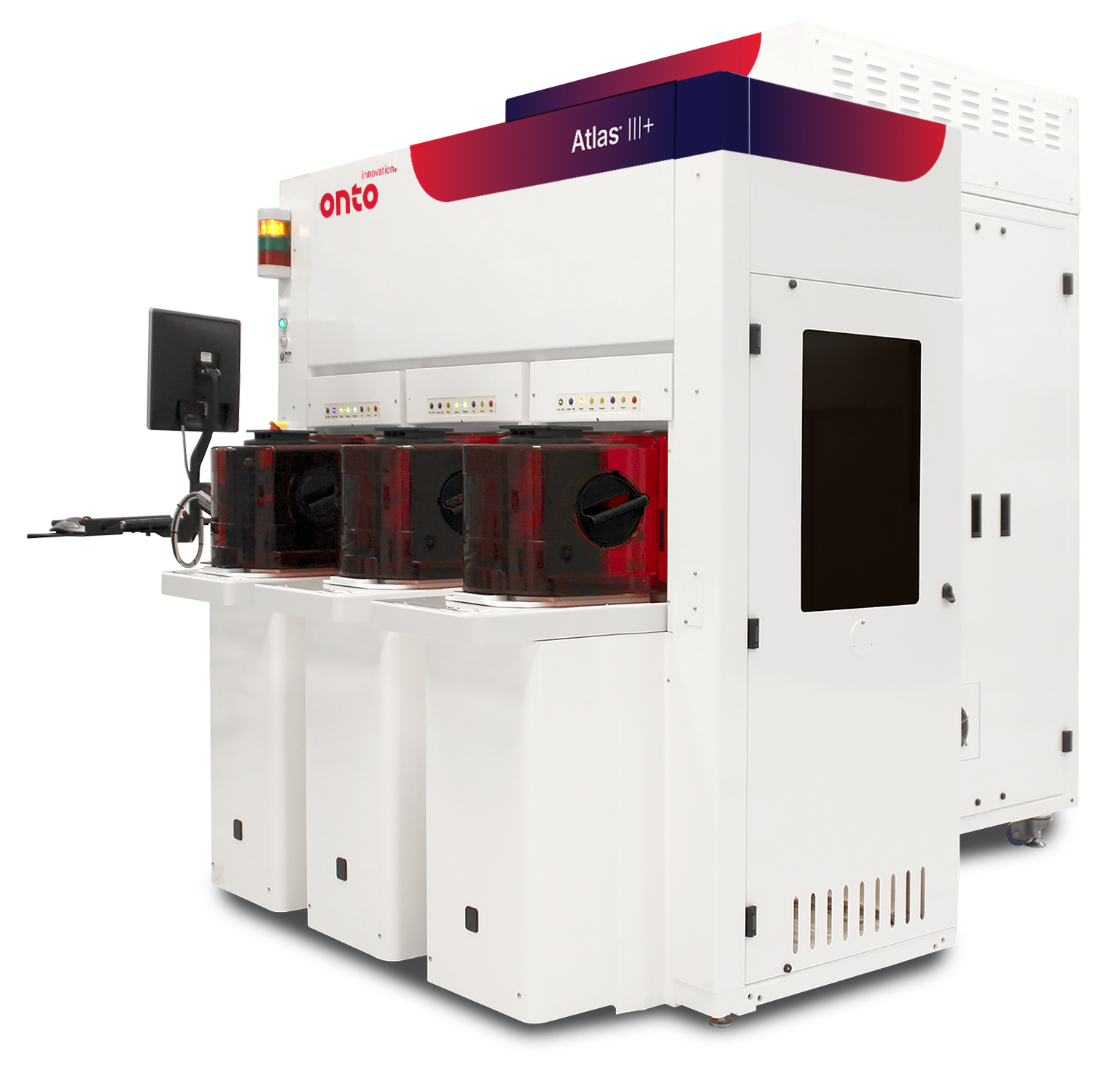

Atlas® III+ System

The Atlas III+ system provides dependable OCD and thin film metrology for established technologies, with flexible performance across a wide range of process layers and device types.

Product Overview

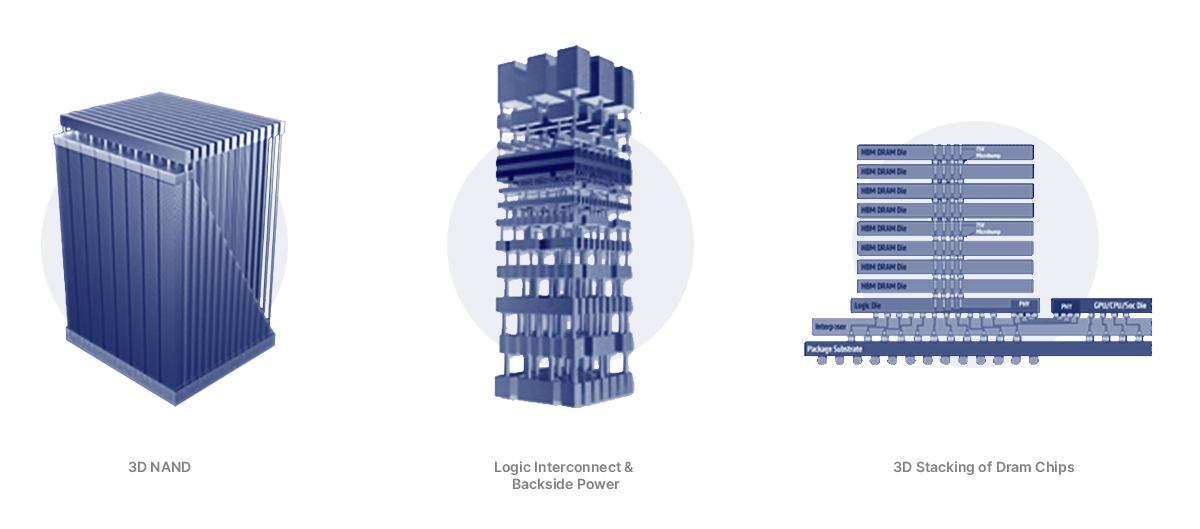

The Atlas III+ system is a widely adopted inline OCD metrology system, known for its robust and reliable solutions across all OCD and film layers from FEOL to BEOL. With its information-rich optical architecture, powerful OCD and machine learning analysis engine, the Atlas III+ system excels in advanced logic, 3D NAND and DRAM device processes. Extending metrology performance to sub-angstrom precision and accuracy levels, this system enables advanced process control across a broad range of applications in high volume manufacturing. The Atlas III+ system incorporates a proprietary spectroscopic reflectometry and spectroscopic ellipsometry solution, and when combined with Onto Innovation’s Ai Diffract™ OCD analysis software, it enables process control of every critical manufacturing unit operation. Users can gain insights into complex structure profiles across etch, clean, deposition and CMP steps.

Applications

- 3D-NAND

- DRAM: Logic and Foundry

- Specialty: CIS, AR/VR, Power & RF etc.

Intelligent Line Monitoring & Control with Integrated Metrology

Enhance CMP process control with a connected metrology approach that feeds forward data from standalone OCD or films metrology to integrated metrology, connected through AI-driven analytical software. This approach, powered by advanced modeling and analysis tools, can deliver high-precision, high-throughput results—minimizing or eliminating the need for and cost of new TEM data and enabling accelerated time to solution, faster excursion detection, reduced cost and improved Cpk.

Enhancing CMP Process Control with Intelligent Line Monitoring & Integrated Metrology

As semiconductor manufacturers push the boundaries of performance and functionality—driven by high-performance computing and AI applications—chemical mechanical planarization (CMP) processes increase in intensity complexity. New logic transistor designs, 3D NAND stacking, and DRAM integration introduce more CMP layers and tighter process windows.

Do you have an Atlas III+ system question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields

Aspect® System

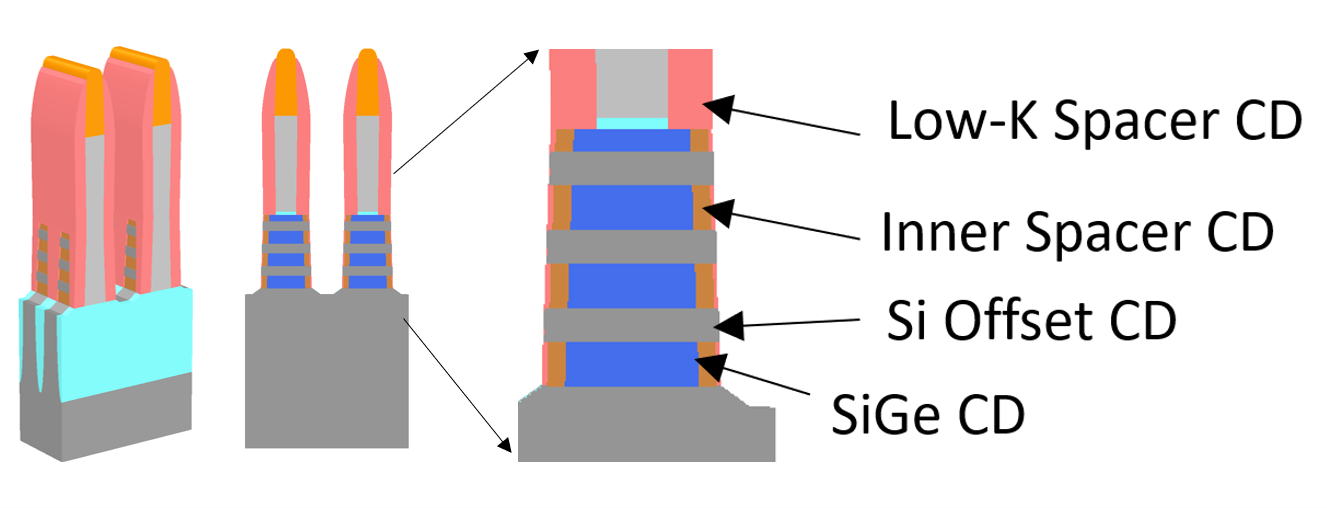

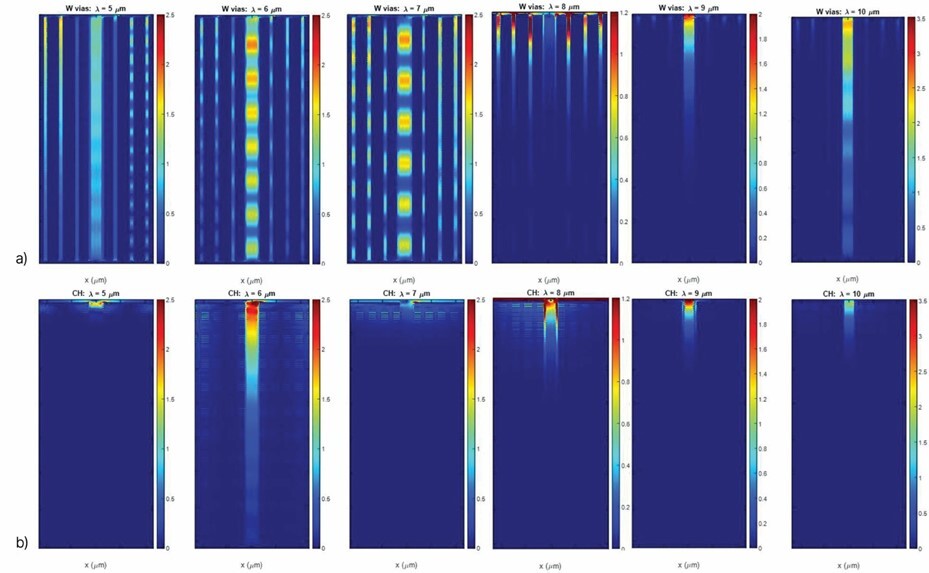

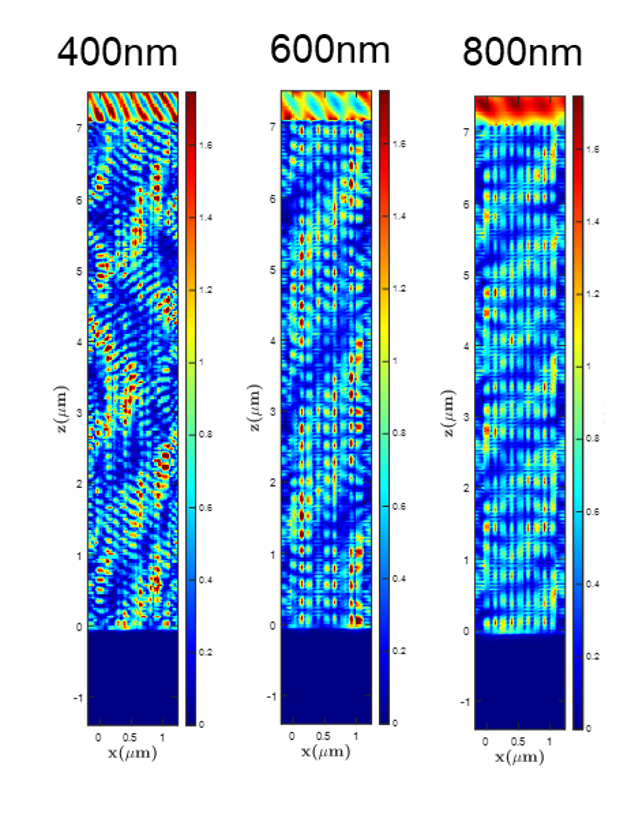

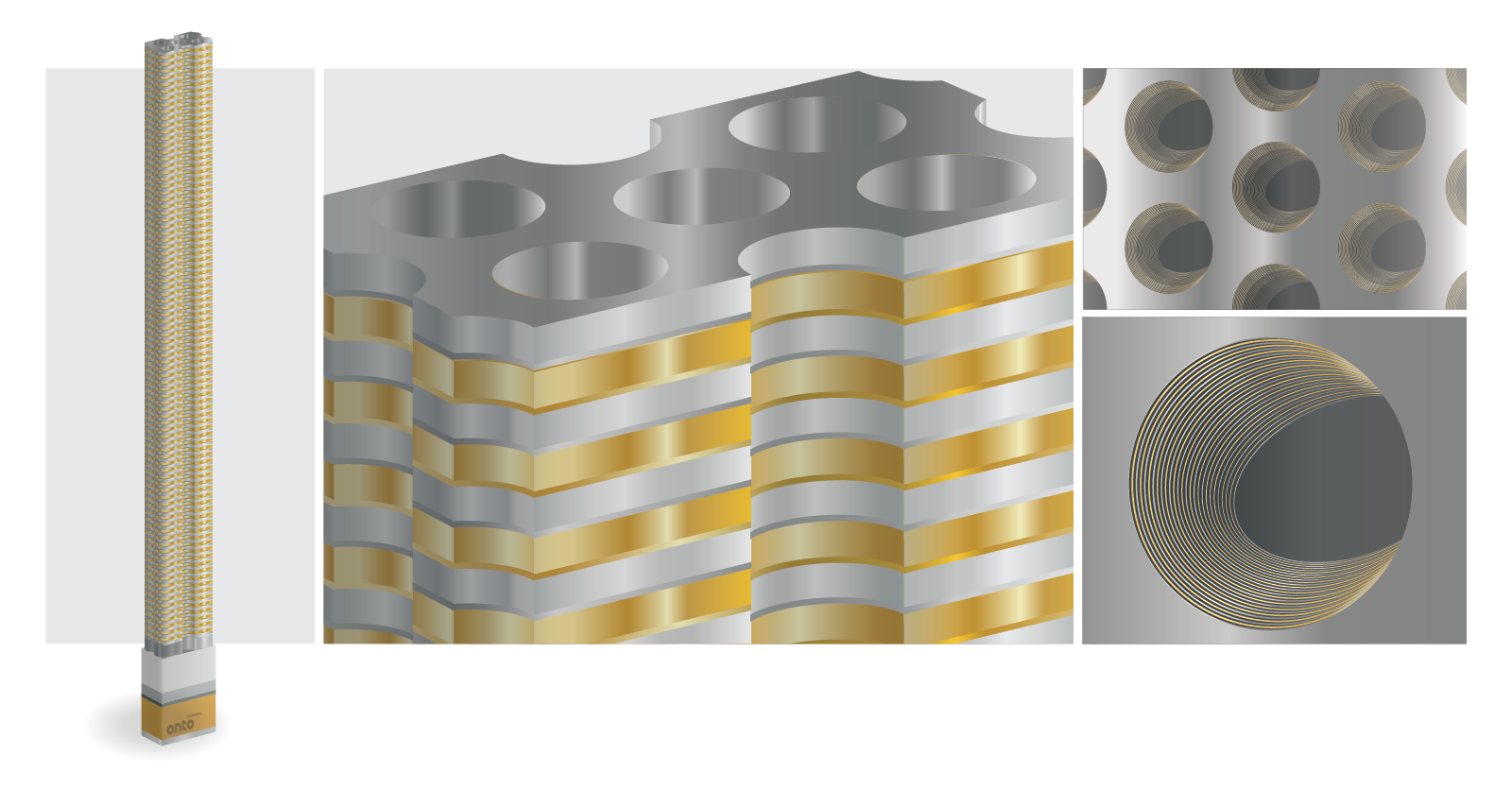

The Aspect System is a revolutionary in-line, non-destructive infrared optical critical dimension (IRCD) system measuring Z-dimension profiling of high aspect ratio structures to enable critical process control. It meets the needs of leading-edge customers with its high speed and process coverage.

Product Overview

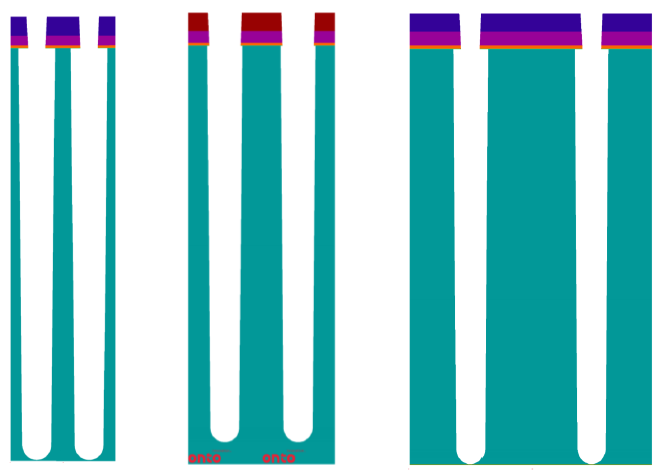

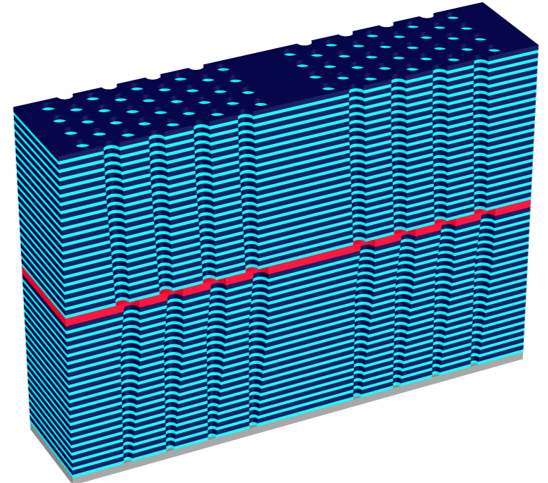

As the semiconductor industry relentlessly pursues density and power scaling, more and more high aspect ratio (HAR) processes are used across multiple device segments, especially in advanced memory such as 3D NAND and 3D DRAM. The Aspect metrology system was designed with these ongoing architectures and scaling strategies in mind. Aspect metrology has demonstrated superior performance across multiple customer devices through a unique proprietary IRCD system that provides full profiling capability to enable critical process control, with the speed and process coverage that customers require.

The Aspect system is powered by a software analysis engine, Ai Diffract™, that provides up to 90% faster time to solution which extends the industry leading NanoDiffract® software by leveraging extensive machine learning capabilities along with high fidelity modeling. The result is a simultaneous improvement in metrology performance along with a significant time to solution reduction.

Applications

- Etch, cleans, and deposition for 3D NAND

- Etch, cleans, and deposition for 2D and 3D DRAM

- Deep trench etch and doping for CIS

- Deep Trench etch in Power Devices

- On-device materials characterization for EPI process

Featured Markets

Hybrid Bonding Process Control Solution

Hybrid bonding enables ultra-dense 3D memory interconnects with up to 1,000x more connections than microbumps. Achieving high yield requires stringent process control, including monitoring topography and detecting particles, cracks and voids. Measuring dishing in copper pads provides valuable insight into surface conditions. Together, these process control insights contribute to improved device reliability and performance.

Enabling In-Line Process Control for Hybrid Bonding Applications

As demand grows for high-performance computing (HPC) and AI-driven applications, manufacturers are turning to hybrid bonding to enable the ultra-dense 3D integration required for next-generation chip architectures. This advanced packaging technology presents significant process challenges. Surface preparation must be precisely controlled to eliminate particles, excess recess, and copper pad dishing, all of which can compromise bond quality. During pre-annealing, particle-induced gaps and wide bonding gaps can prevent proper wafer contact. Post-annealing, the formation of dielectric and metal voids introduces further risks to electrical performance and long-term reliability.

Do you have an Aspect system question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields

NSX® 330 System

The NSX 330 system offers advanced macro inspection for a wide range of defect sizes at high throughput, with optional 3D metrology integration.

Product Overview

The NSX 330 system features robust platform technology with high-acceleration staging, high-speed multi-processor computing and flexible software. With over 1,000 installation worldwide, the NSX 330 System offers 2D inspection and metrology at high throughput and a broad portfolio of 3D sensors supporting critical advanced packaging applications. These include wafer-level metrology for micro bumps, RDL, kerf, overlay, and through silicon via (TSV) in a single wafer load.

Accommodating wafers from 100mm to 330mm, the system features a versatile objective turret, programmable light tower, and multiple dark field illumination modes. Additional features include resolution flexibility, unique handling solutions, and comprehensive software for recipe sharing and offline analysis. The NSX 330 system, with optional edge and backside inspection via the EB40 module, provides a comprehensive all-surface inspection solution packaging technology challenges.

Applications

- Macro inspection: whole wafer, and film frame

- Gel and waffle pack inspection

- OQA and post saw

- Post Probe and Testing

- Substrate thickness, TTV, and bonded wafer thickness stack thickness (carrier, adhesive, product wafer and total stack)

- Via depth thick and thin RST

- Bow and warp

Featured Markets

Do you have an NSX 330 system question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields

F30™ System

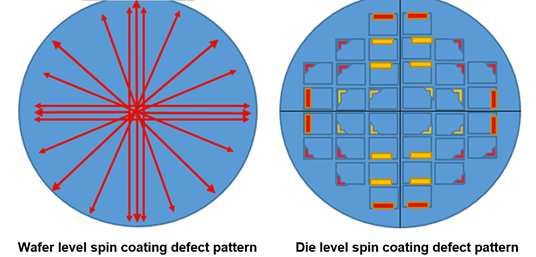

The F30 system is designed to blur the lines between dark field micro inspection and traditional macro inspection, providing automated defect inspection for front-end and outgoing quality (OQA) applications.

Product Overview

The F30 automated defect inspection system combines high resolution and throughput to drive fab yield and productivity. A five-objective turret enables resolution-throughput flexibility, while its multi-channel illumination including brightfield, darkfield, high-angle ring light, and IR-Review addresses the requirements for today’s multi-process inspection applications. Equipped with an advanced productivity suite (waferless recipe creation, simultaneous FOUP, recipe server and tool matching), the F30 System redefines inspection cost of ownership expectations. The system can handle 100mm – 300mm wafers can be paired with the edge and backside module (EB40) to provide an all-surface inspection solution.

Applications

- After develop inspection (ADI)

- Post CMP inspection

- After etch inspection

- Fab Outgoing QA

Featured Markets

Do you have a F30 system question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields