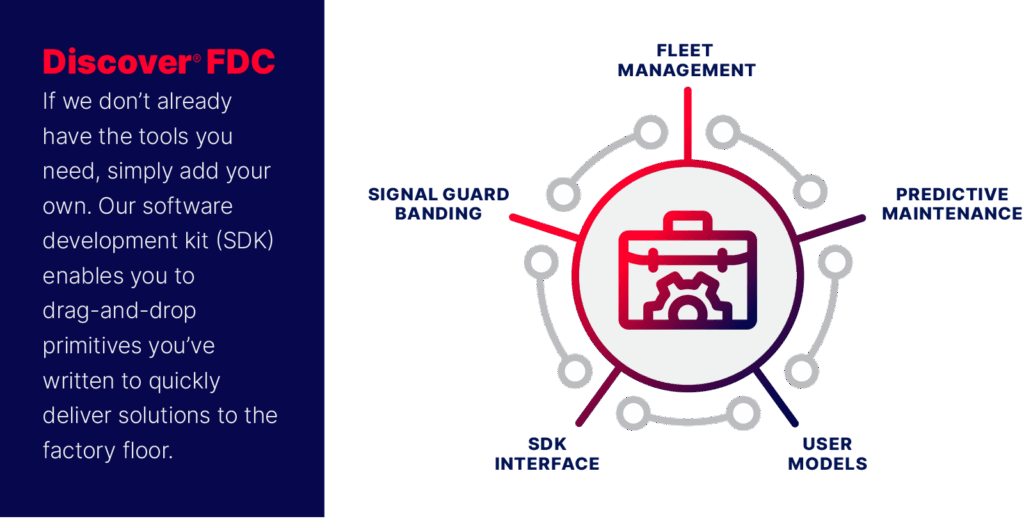

Discover® FDC Software

Discover FDC software is part of a robust data management suite, serving as the ideal gateway to digital transformation and unlocking Industry 4.0 best practices for impactful results.

Product Overview

Discover FDC software transforms tool sensor data into actionable insights. It empowers manufacturers to optimize fab efficiency, scaling seamlessly to high-volume manufacturing while reducing tool downtime by detecting anomalies early. With its diverse set of flexible controls and real-time data analysis, Discover FDC software enhances productivity, improves cycle time and increases equipment availability (OEE). Its user-friendly interface integrates advanced process control, allowing engineers to pinpoint issues and bring equipment online faster. Proven across processes and operational modules, it eliminates wasted time and energy by preventing idle tools and minimizing scrapped wafers. When connected to Discover Defect and Discover Yield software, Discover FDC software identifies meaningful correlations that drive even greater efficiency and production results. This robust solution redefines control, setting a new standard for achieving maximum enterprise-wide factory performance. That’s control, redefined.

Applications

- Memory

- Logic

- ASIC

- Compound-Semi

- HDD

- Advanced Packaging

Do you have a Discover FDC software question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields

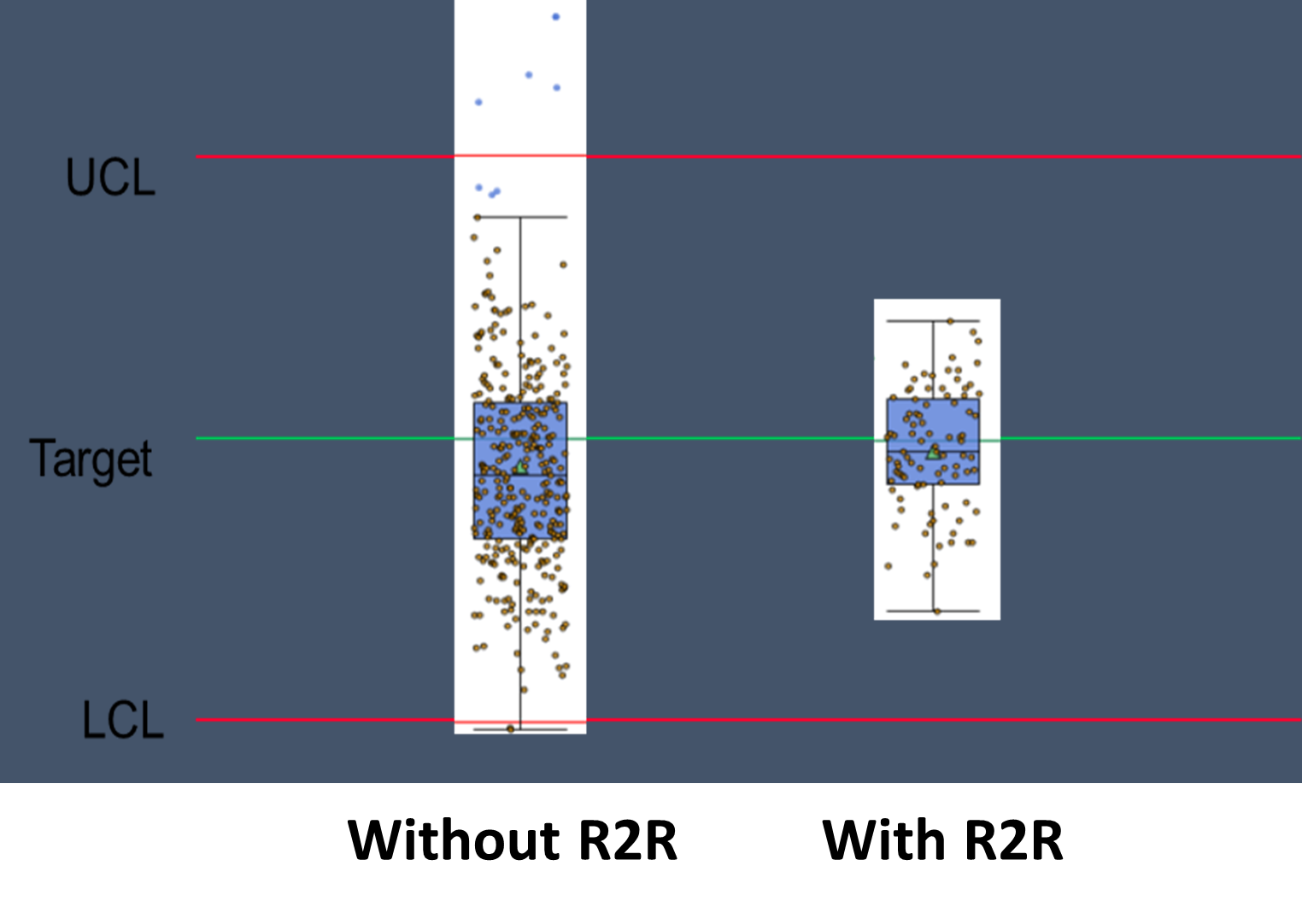

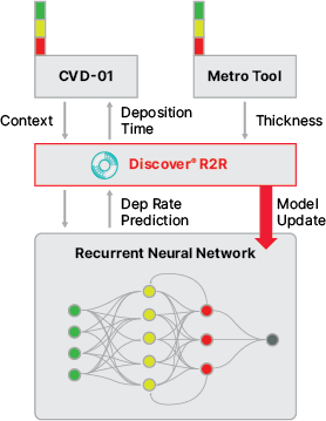

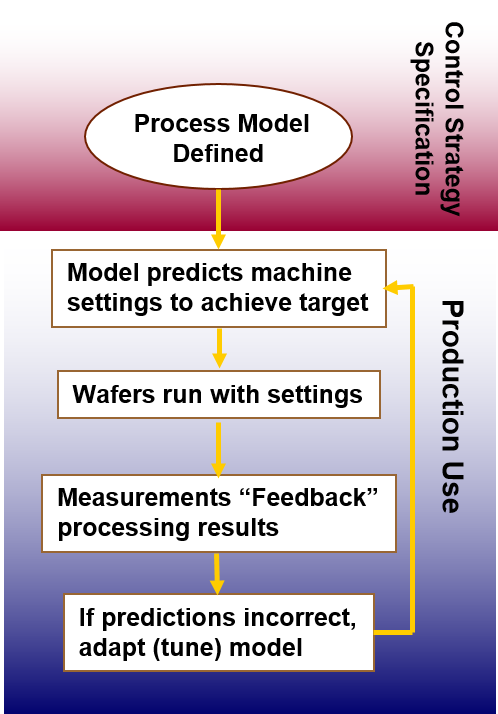

Discover® Run-to-Run Software

Discover Run-to-Run software boosts profits and productivity with swift deployment on any process or tool, increasing Cpk and throughput while reducing pilot wafers, engineering time and manufacturing costs.

Product Overview

Discover Run-to-Run software is a feature-rich application that enables advanced supervisory process control, surpassing traditional statistical methods. It ensures precise process goals. For example, achieving desired thickness is possible through tailored adjustments of machine parameters like deposition duration or pressure settings. Designed for high-mix production, it allows seamless transfer of control strategies across factories for operational flexibility. Proven globally, it operates thousands of tools across hundreds of processes continuously. With its adaptable, framework-based APC solution, Discover Run-to-Run software enables rapid factory-wide deployment, delivering significant and immediate return on investment while enhancing consistency, productivity and efficiency.

Applications

- Memory

- Logic

- ASIC

- Compound Semi

- HDD

- Advanced Packaging

Do you have a Discover Run-to-Run software question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields

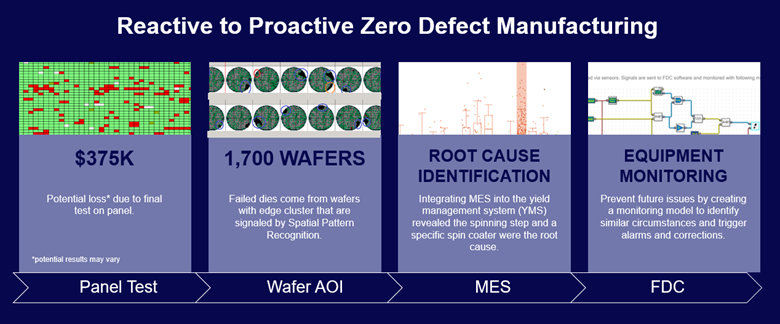

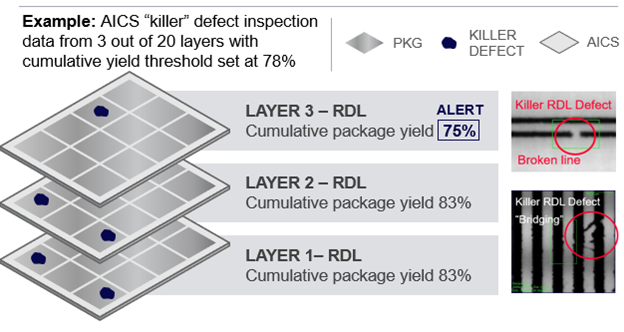

Discover® Yield Software

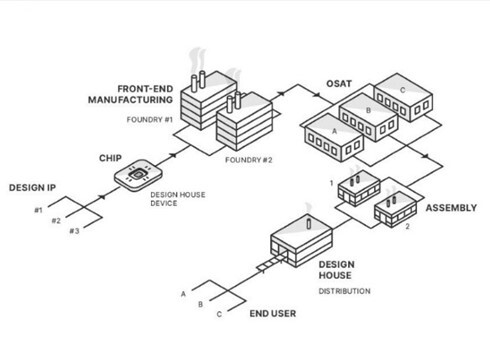

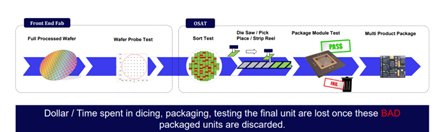

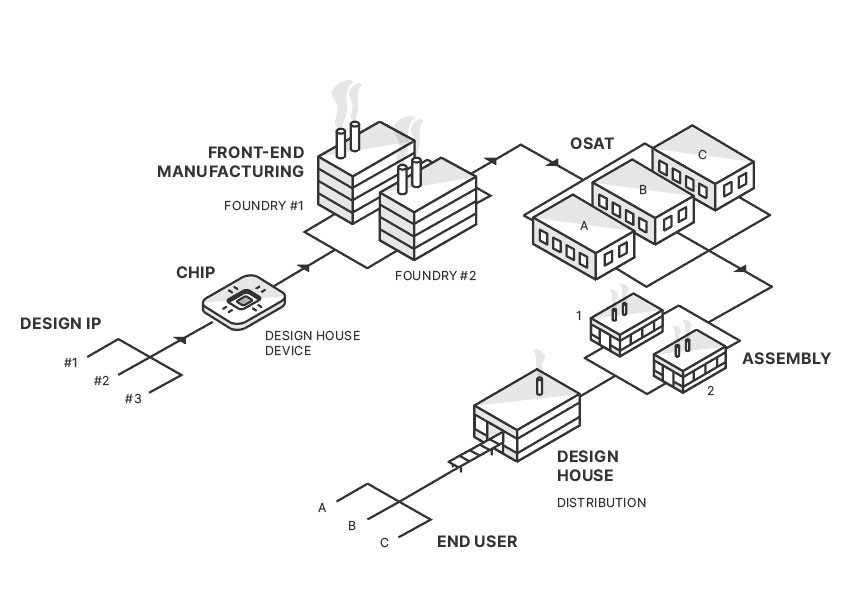

Discover Yield software is a complete yield management enterprise platform that combines parametric, defect and yield optimization with data mining and workflow development across all data sources from memory and design to assembly and packaging.

Product Overview

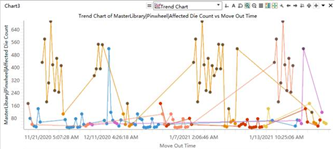

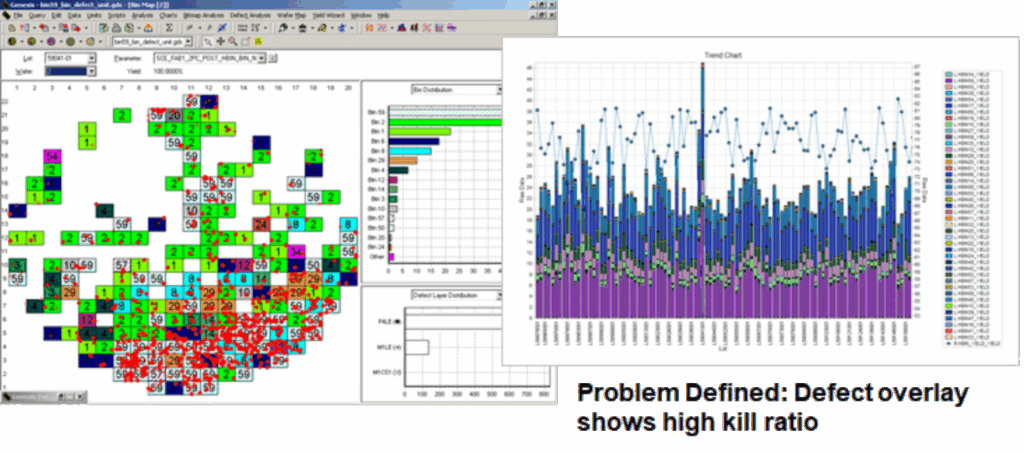

Discover Yield software helps reduce the time it takes to find root causes of yield excursions and enables manufacturers to broaden their analysis scope for better yield management.

The software includes data acquisition and integration, a development environment through workflow and scripting, and specialized analysis algorithms to identify domain-specific issues, such as data mining, spatial anomalies, wafer processing sequence problems, commonality of effects, system and random yield loss, chamber matching, tool events, traceability and more. In addition, Discover Yield software provides distinct tools – principal components and multivariate analysis of variance (MANOVA) – that allow systematic, simultaneous examination of multiple variables. Discover Yield software’s database architecture for genealogy uniquely supports value chain predictive analytics.

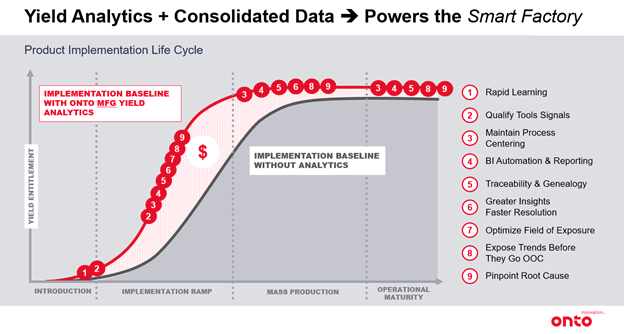

Improving baseline yield with analytics

Applications

- End-to-end root cause finding for semiconductor manufacturing

- Integrate with Discover AI for process & yield prediction

- Genealogy capability ties context information from bare wafer to integrated package

- Enable rapid equipment studies and equipment matching

- Integrate with Reports service to automate repeat reports for traceability

Do you have a Discover Yield software question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields

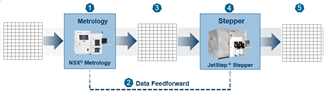

StepFAST® Software

An advanced feed-forward lithography software solution for fan-out panel level packaging that enhances yield and throughput by correcting die placement errors through external measurements, predictive analytics and adaptive shot control.

Product Overview

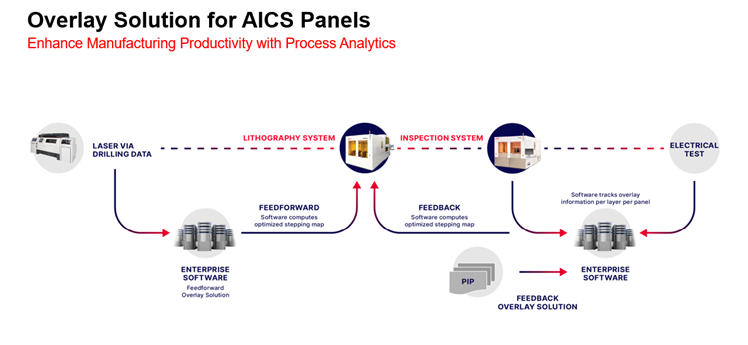

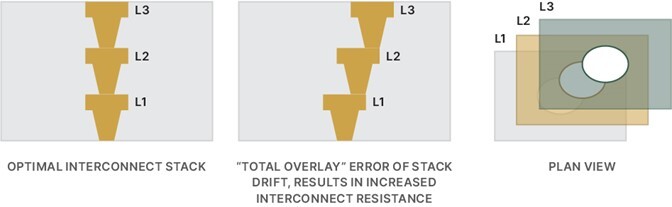

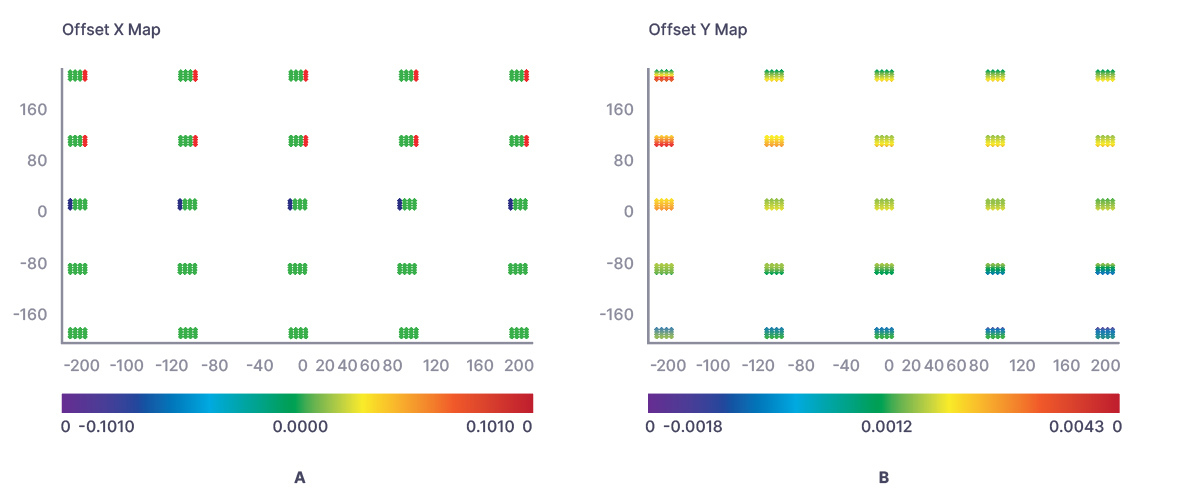

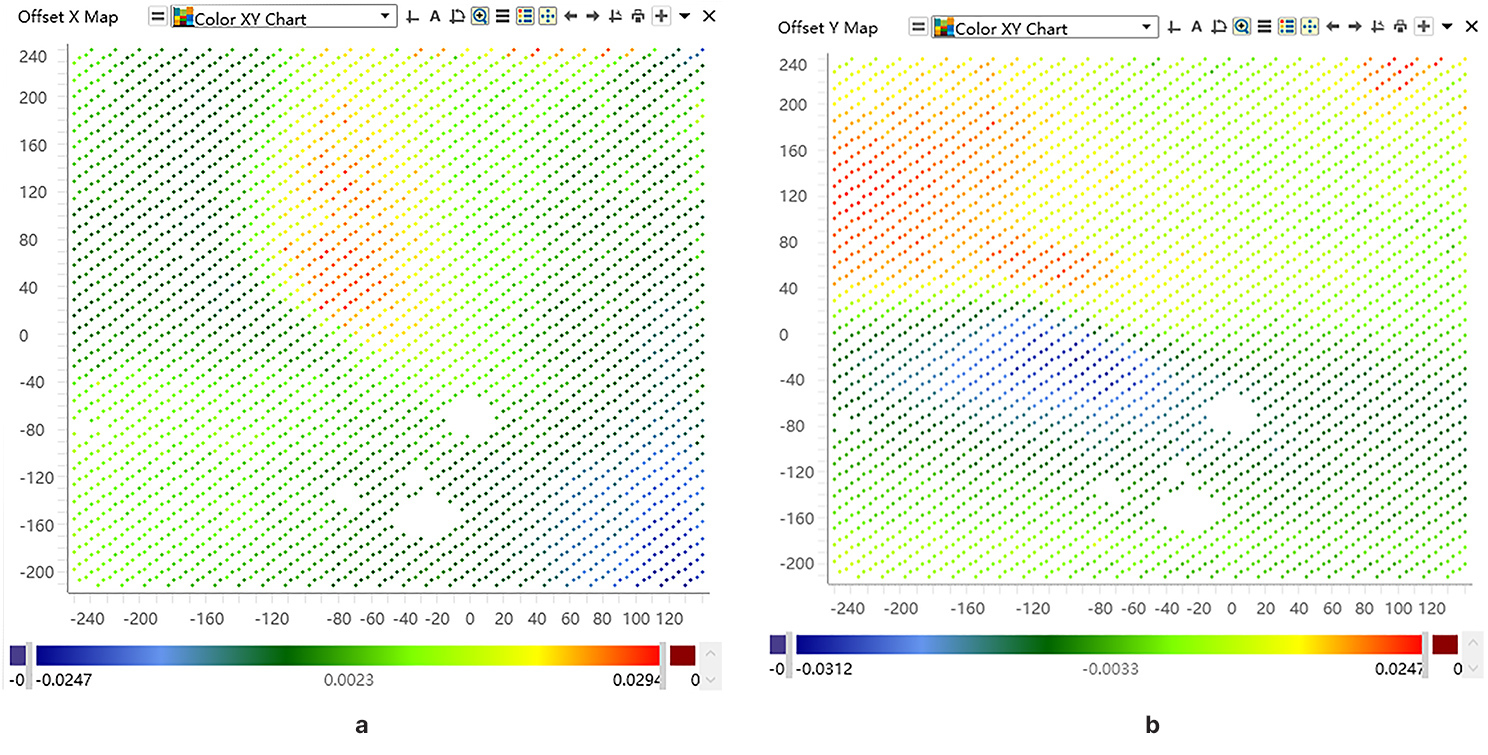

StepFAST® software is Onto Innovation’s advanced lithography software solution tailored for fan-out panel-level packaging, where die placement errors and material instability can significantly impact yield and productivity. StepFAST® software uses a feed-forward adaptive shot approach, integrating high-speed die placement measurements from the Firefly® system and applying real-time corrections to every shot of the JetStep® lithography tool. This external measurement strategy doubles throughput compared to traditional on-tool (self-metrology) methods. The software also incorporates predictive yield analysis, enabling dynamic adjustment of exposure field sizes to balance throughput and overlay accuracy. By automating reticle selection and optimizing field coverage, StepFAST® software ensures efficient panel exposure while minimizing registration errors—from ±50µm down to under ±3µm. With advanced analytics, StepFAST® software transforms lithography into a flexible, high-efficiency process, delivering substantial improvements in yield, throughput, and cost of ownership for panel-level packaging applications.

Applications

- Panel-level packaging

Featured Markets

Adaptive Shot Lithography Solution

Die shift on reconstituted panels can significantly impact both productivity and yield. To address this challenge, we use a parallel die placement measurement process and advanced analytics to provide a means to balance productivity against yield. Our integrated lithography cell, featuring Firefly inspection, StepFAST software, and JetStep Lithography, delivers industry-leading throughput and yield for fan-out panel level packaging.

Overcoming FOPLP Die Placement Error

It is well understood that advanced packaging applications require high performance, low cost, increased functionality and improved reliability that 2.5D and 3D packaging solutions provide. Fan-out panel-level packaging (FOPLP) is one of the technologies that has the potential to meet these packaging requirements.

Do you have a StepFAST software question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields

Discover® AI Software

Discover AI software leverages high-quality data input to provide valuable insights into processes and actionable predictions for process, yield and efficiency improvements through integration with the Discover data platform.

Product Overview

Discover AI software is a disruptive technology that reshapes the way we approach manufacturing line control and yield analysis. It leverages the latest in machine learning and artificial intelligence to identify actionable improvements and connections in data that a human could not. The software’s optimization engine adds a powerful machine learning analytical method to an already sophisticated toolbox of process improvement applications.

By analyzing any set of conceivable inputs and outputs, Discover AI software identifies relationships and interactions that lead to positive operational changes. Easily understood visuals empower even casual users to understand what is important before making adjustments.

Discover AI software evaluates multiple models and suggests the optimal one for the data. Using machine learning, it examines interactions between in-process inputs and results for any semiconductor product family and recommends changes to in-process targets. Licensed as a service, it enables users to leverage an on-demand infrastructure to apply easily understood workflows for complex analytics without the overhead.

Applications

- Yield Optimization

- Virtual Metrology

- Process prediction & tuning

- Embedded AI – process digital twin

Do you have a Discover AI software question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields