Yield Optimizer™ Software

Yield Optimizer software is part of a comprehensive next-level data management portfolio. It reimagines manufacturing line control and analytics to explore the impact of previously invisible factors in day-to-day factory operation.

Product Overview

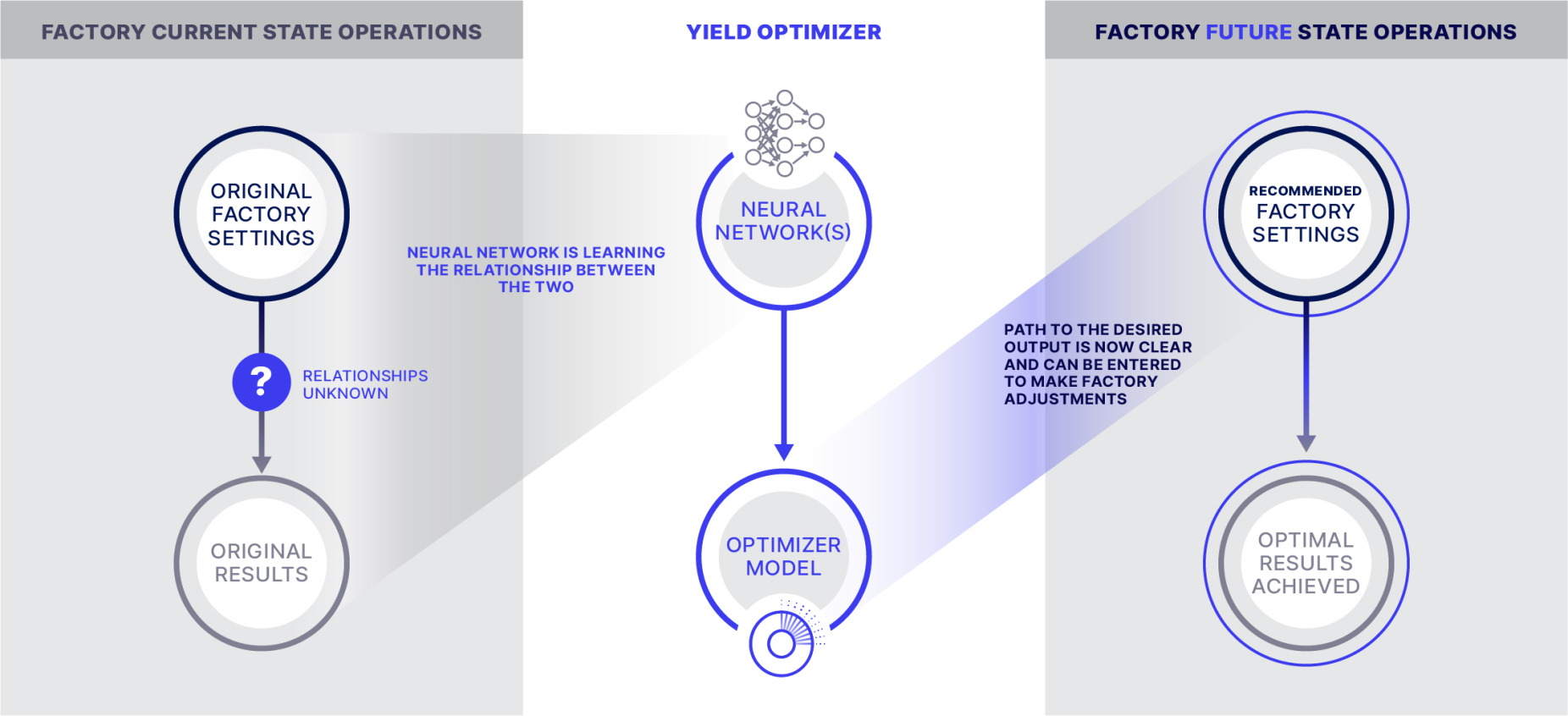

Yield Optimizer software is the next incarnation of analytics on the evolutionary scale. The software’s disruptive technology analyzes relationships between multivariant data and their complex interactions. By examining any set of conceivable inputs and outputs, Yield Optimizer software identifies the relationships and interactions that lead to positive operational changes. Easily understood visuals empower even casual users to understand what is important before making adjustments.

Yield Optimizer software evaluates multiple models and suggests the best one for the data. Using machine learning, it examines the interactions between in-process metrology readings and end-of-line test results for any semiconductor product family and recommends changes to the in-process metrology targets. When licensed as a service, it enables users to leverage an on-demand infrastructure to apply easily understood workflows for complex analytics without the overhead.

Applications

- Yield Prediction

- Process Targeting

- Design of Experiment (DOE) Assistant

- Troubleshooting

Neural networks model today’s data to achieve tomorrow’s in-line targets

Users across the fab benefit from Yield Optimizer software’s easy-to-apply analytics

Do you have a Yield Optimizer software question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields

TrueADC® Software

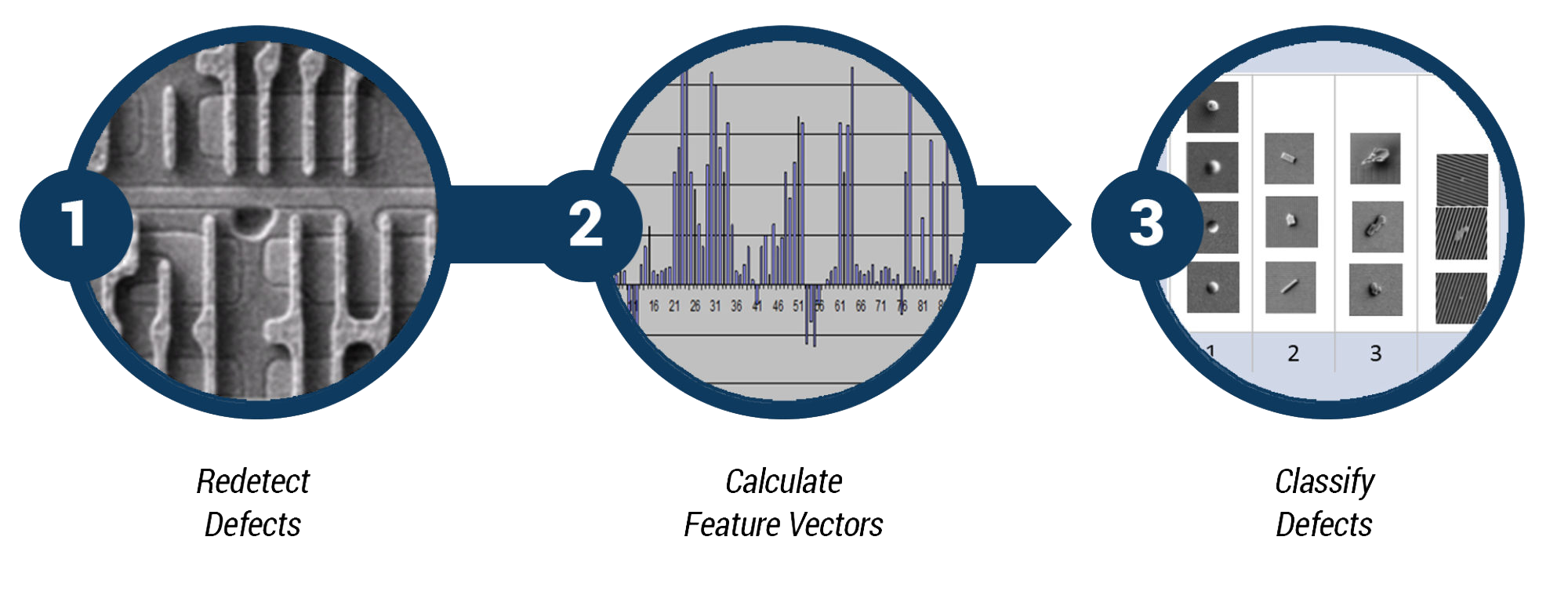

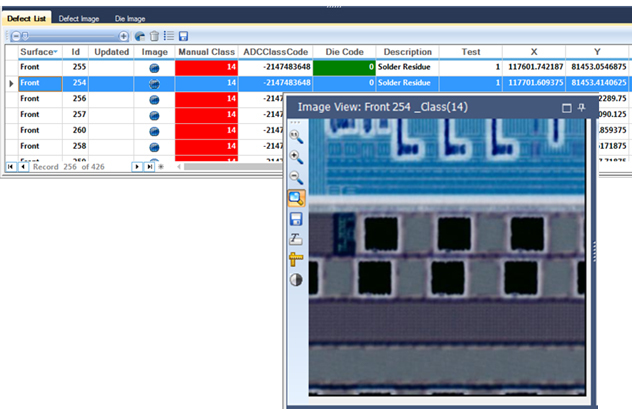

TrueADC software enhances defect classification accuracy and efficiency by combining deep learning, real-world defect modeling, and intuitive workflows—reducing manual review and improving decision-making across all wafers and surfaces.

Product Overview

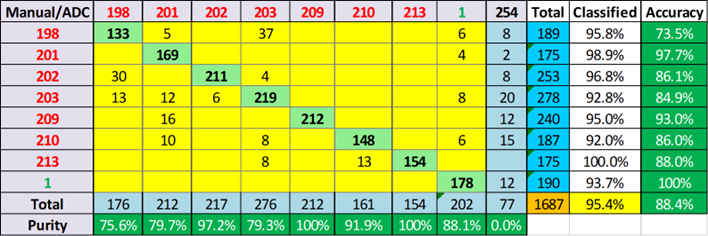

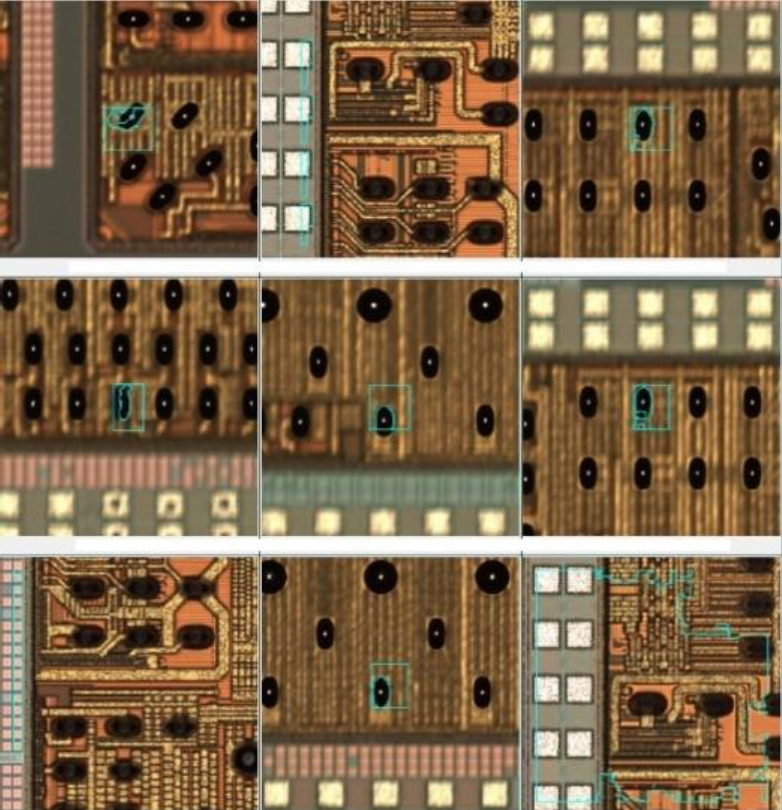

TrueADC software sets a new standard in defect classification by combining advanced analytics with intuitive usability. Seamlessly integrated with Onto Innovation’s AOI tools and Discover platforms, TrueADC software enhances inspection value through a proprietary hybrid decision-making process across all wafers and surfaces.

With over 70% reduction in manual review, TrueADC software intelligently flags low-confidence defects as “unknown” to avoid misclassification. Its dynamic defect library method uses real defect examples—unlike traditional ADCs that rely on approximations—delivering more accurate and efficient results.

Supporting adder, repeater, SPR codes, and region-of-interest data, it enables precise tool sampling and binning. Operators can quickly classify new defects without altering recipes, while the software’s multi-engine mode leverages deep learning to reduce overkill and underkill.

From model development to identifying hard-to-isolate defects, TrueADC software empowers engineers with greater clarity, control, and confidence.

Applications

- On-tool with Onto AOI systems

- Inline defect classification

- Dynamic defect library utilization

- Support for advanced defect types

Do you have a TrueADC software question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields

Discover® Defect Software

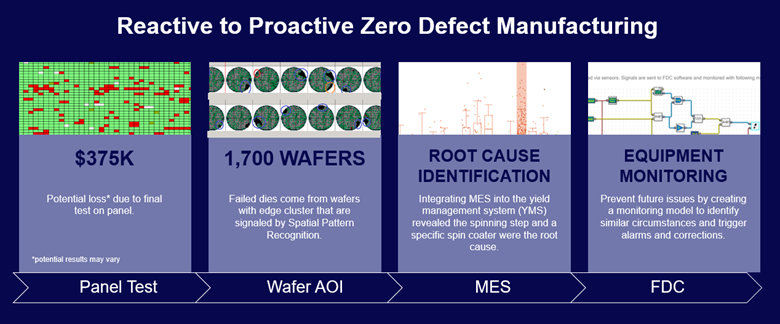

Discover Defect software provides actionable value to raw data through its intelligent, real-time analytics techniques. Inline monitoring, alarming and reporting is standard with all inspection tools, as well as offline fab-wide analysis with all licensed third-party tools.

Product Overview

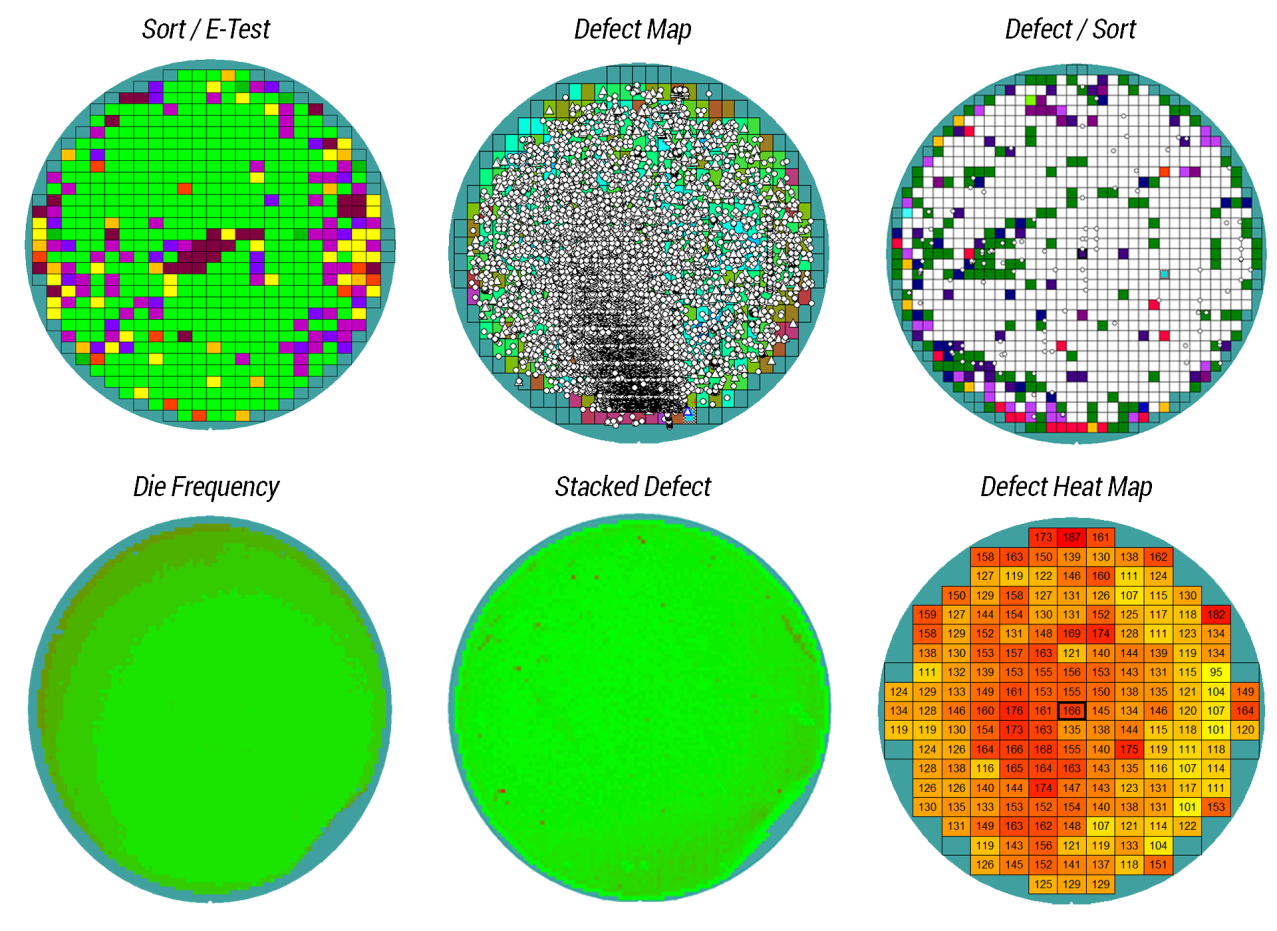

Discover Defect software readily integrates into any wafer or panel production environment. It flexibly brings together all pertinent fab information, including defect, sort, metrology, wip, and electrical, into a single big data-capable solution. Its speed and up-time are world class.

Discover Defect software will pay for itself repeatedly by enabling its users to identify and solve problems, as well as to monitor and alarm on known areas of concern quickly and accurately. The product is designed to improve both throughput and yield while simultaneously reducing manufacturing costs.

Expand your yield analysis capabilities with the power of the Discover Yield software module. Discover Yield software’s patented data mining capabilities and advanced statistical analysis allow for highly sophisticated, interactive root cause analysis. Discover Yield software gives you the power to deep-dive into your data to uncover even the most difficult-to-identify systemic process issues.

Applications

- Memory

- Logic

- Foundry

- Compound-Semi

- LED

- Advanced Packaging

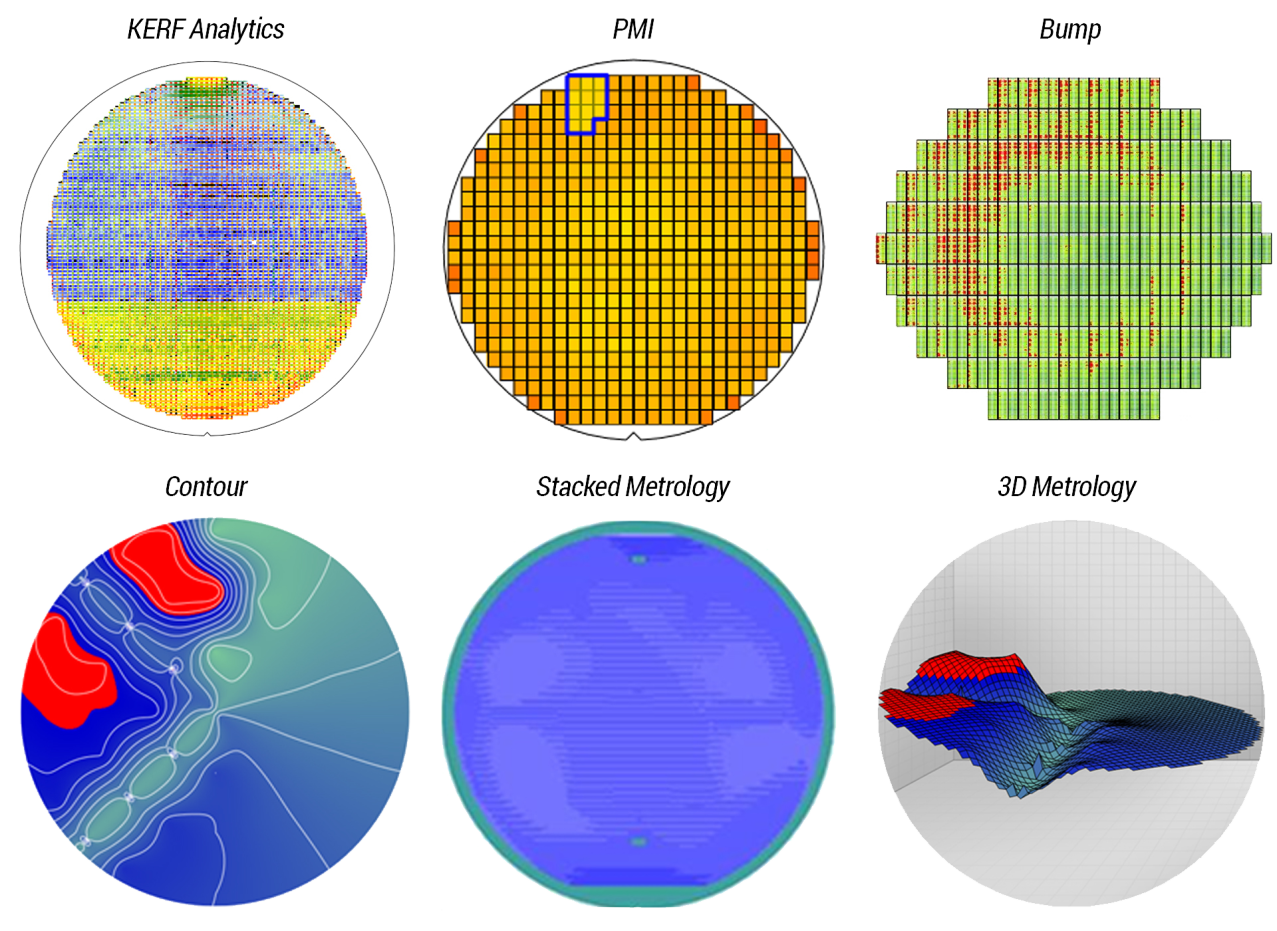

Discover Mapping Suite

Comprehensive mapping suite that covers all aspects of semiconductor processes

Discover High Volume Metrology (HVM) Bump Server

Targeted modules specific to customer challenges

Do you have a Discover Defect software question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields

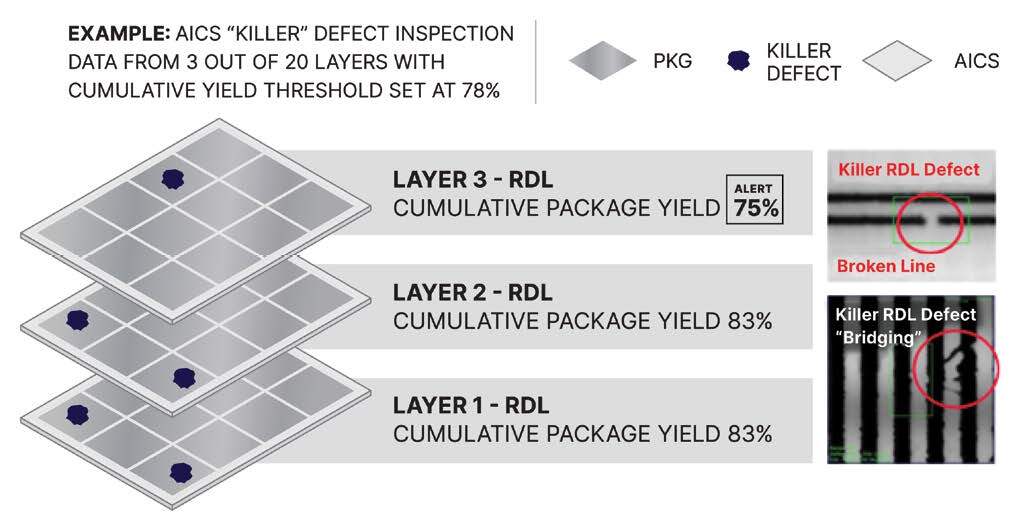

Discover® Patterns Software

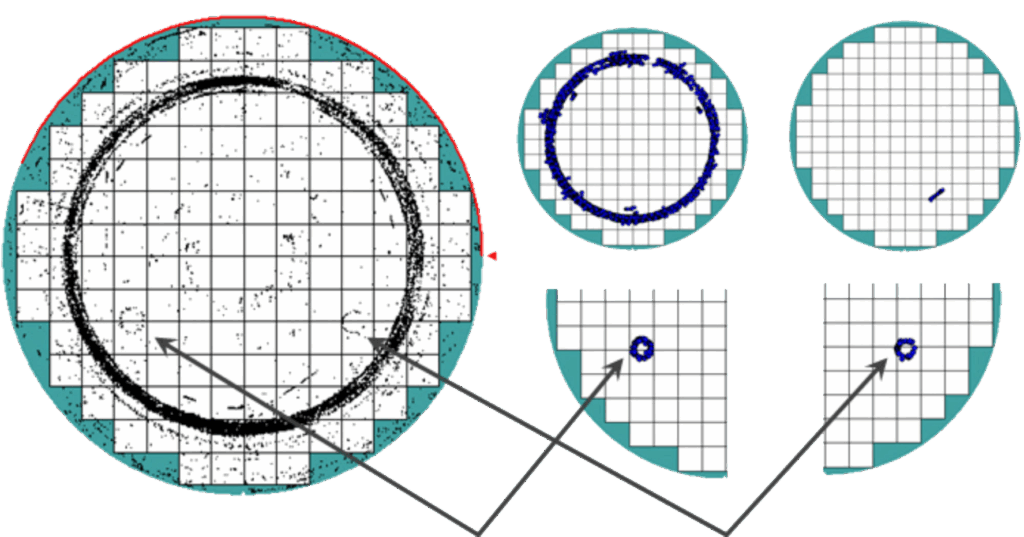

Discover Patterns software quickly and easily traces patterns back to yield-killing process issues.

Product Overview

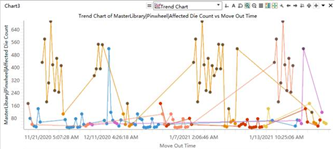

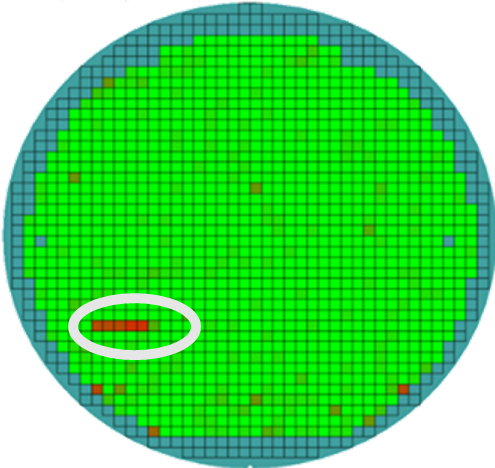

Discover Patterns software combines sort and defect spatial patterns utilizing proprietary machine learning (ML) algorithms, to uncover hidden patterns that would have been otherwise lost. Segmentation allows users to eliminate noise and extract definitive patterns from a larger pattern or a seemingly random array of defects. Wafer stacking enables the handling of faint defect trends to more clearly isolate patterns.

Combining Discover Patterns software with the Discover Defect platform multiplies the value of your defect management infrastructure by intelligently identifying and acting upon known patterns in real time. It marks defects and die affected by patterns for deeper understanding of processes and reduces the need for human intervention.

Highlight all patterns, not just the dominant ones

Applications

- Memory

- Logic

- Foundry

- Compound-Semi

- LED

- Advanced Packaging

Do you have a Discover Patterns software question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields

Discover® Review Software

Discover Review software is an intuitive classification solution that rapidly guides users through the sequences of defect classification and correlation.

Product Overview

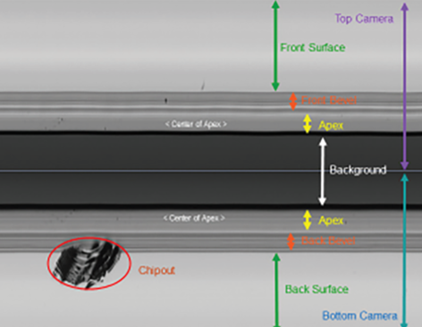

Discover Review software improves system productivity by enabling its users to review results offline. Users can examine defect results from any inspection tool connected to the Discover server. Multiple client usage enhances productivity by supporting concurrent review with overwrite protection while partial review status enables operator shift changes. Visualize defects individually or collectively using an interactive, all-surface (front, edge, back) wafer map viewer. The gallery review mode allows users to select individual or multiple images by wafer or die for fast classification and defect comparison. Discover Review Software also includes a large number of wafer map exports and customizable reports.

Point-to-point review and advanced image browsing

Applications

- Memory

- Logic

- Foundry

- Compound-Semi

- LED

- Advanced Packaging

Do you have a Discover Review software question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields

Discover® RMS Software

Discover RMS software is a complete solution for recipe management. This unified repository automatically delivers the right recipe to the right system at the right time.

Product Overview

Discover RMS software is a factory-level recipe management system that provides a central server repository for all recipes. This system allows desktop access for editing and includes complete version control of all recipes used within the fab.

When coupled with Discover Run-to-Run software, it fundamentally tracks all control changes by automatically inserting recipe values into the recipe body. Working in concert with your MES system, recipes are automatically selected and downloaded to the right tool to be executed on the right material. The recipe sign-off feature enforces a tight control of recipes by ensuring customer approval of any large changes.

The Discover RMS Process

Applications

- Memory

- Logic

- ASIC

- Compound Semi

- HDD

- Advanced Packaging

Do you have a Discover RMS software question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields