Using Machine Learning to Increase Yield and Lower Packaging Costs

Packaging is becoming more and more challenging and costly. Whether the reason is substrate shortages or the increased complexity of packages themselves, outsourced semiconductor assembly and test (OSAT) houses have to spend more money, more time and more resources on assembly and testing. As such, one of the more important challenges facing OSATs today is managing die that pass testing at the fab level but fail during the final package test.

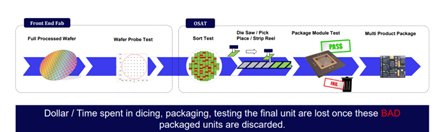

But first, let’s take a step back in the process and talk about the front-end. A semiconductor fab will produce hundreds of wafers per week, and these wafers are verified by product testing programs. The ones that pass are sent to an OSAT for packaging and final testing. Any units that fail at the final testing stage are discarded, and the money and time spent at the OSAT dicing, packaging and testing the failed units is wasted (figure 1).