Driving Down Inspection Time for Critical Aviation and Aerospace Components

In industries such as aircraft engines automotive, companies need to rapidly establish the quality of components, both during production and during repair and overhaul. Many of these components are highly valuable and complex, often with hundreds of features requiring inspection.

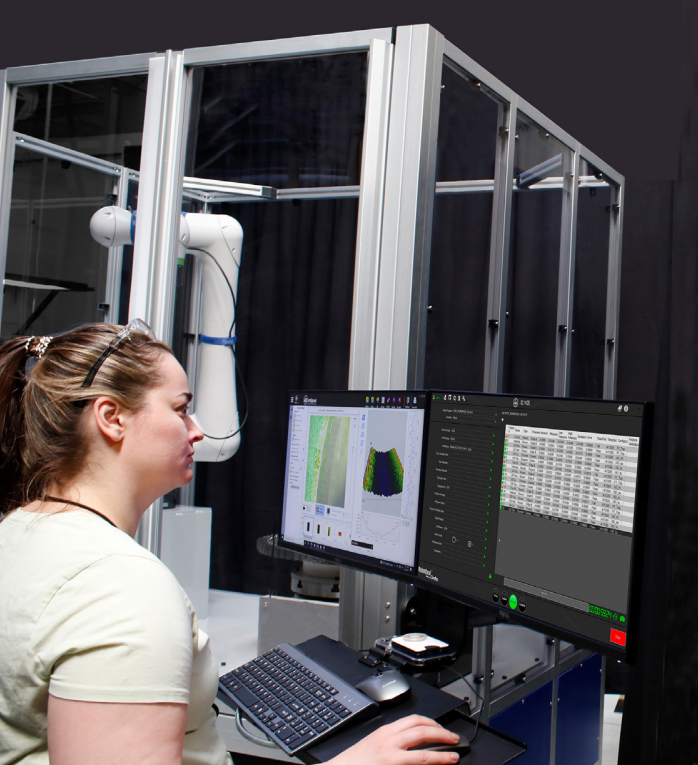

To date, much of this inspection has been completed manually—a slow and subjective process. A new, automated system is now being adopted for rapid, repeatable, non-contact measurement of features and defects on precision machined parts. Combining the flexibility of an industry-proven optical gage and

robotic automation, the system dramatically improves inspection throughput and reliability, recording quantitative data that can be tracked throughout the component’s lifetime.

You Have a Challenge? Let’s talk.

We’d love to connect with you.

Looking to learn more about our innovative solutions and capabilities? Our team of experts is ready to assist you. Reach out today and let’s starts a conversation about how we can help you achieve your goals.

Let’s Talk

"*" indicates required fields