4Di InSpec Automated Measurement System (AMS)

The 4Di InSpec AMS qualifies features and defects on complex geometries and in difficult-to-reach locations – hundreds of times faster than manual inspection.

Product Overview

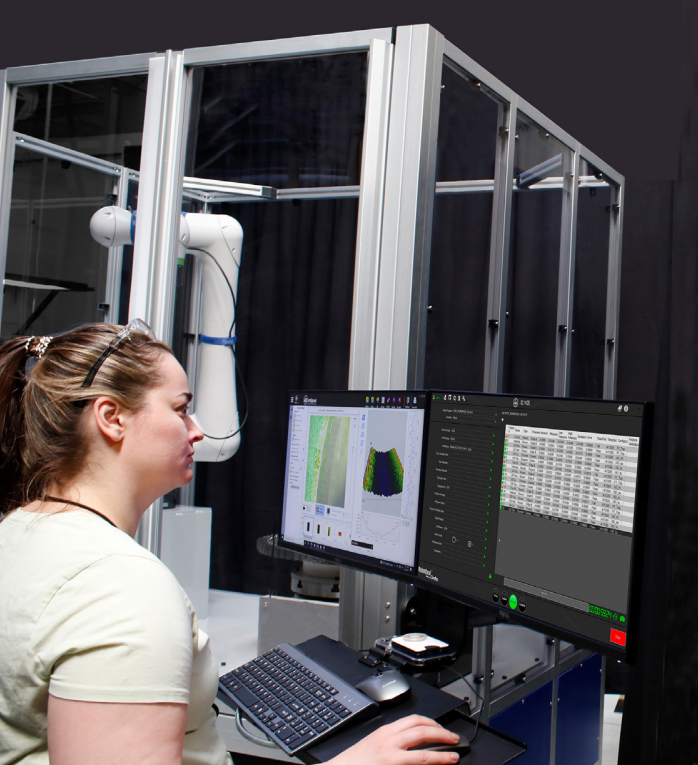

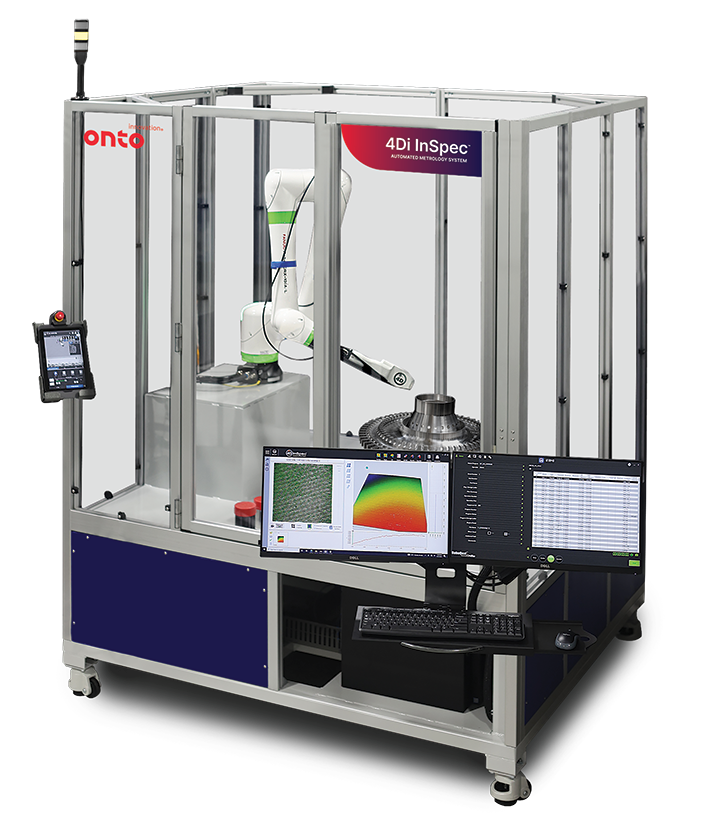

The 4Di InSpec Automated Measurement System is a non-contact optical surface gauge, either the 4D InSpec or 4D InSpec XL, integrated with a choice of collaborative robots, an optional rotary table and a safety cell for rapid production inspection.

This fully automated 3D optical system can measure dozens of edge break features, chamfers, and radii in minutes, vastly improving throughput and driving down inspection costs.

Designed as a turnkey cell for quality control, it is ideal for precision machined components such as turbine blades and rotors, air foils, high pressure compressor blades, blisks and dovetails. The high resolution system can measure in any orientation, on curved surfaces, over large and complex geometries, and in tight spaces or blind locations.

The 4Di InSpec AMS accurately captures complex feature dimensions, enabling more precise part disposition. Its rapid measurement capabilities reduce inspection queuing times, while the ability to measure at multiple locations in the same timeframe ensures part quality.

Applications

- Pits and scratches

- Nicks, dents and bumps

- Edge break, radii and chamfers

- Shot peening and part marking

- Corrosion