IVS 380 System

The IVS 380 System delivers overlay, CD and z-height metrology for advanced packaging, power, compound semi and MEMS, offering world class performance and flexibility to accommodate substrates of different sizes and thickness without hardware changes.

Product Overview

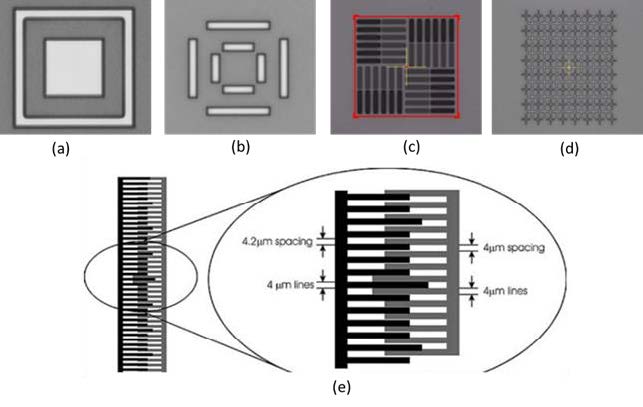

The IVS 380 is an optical overlay, CD & z-height metrology system designed for high volume manufacturing, with SMIF (200mm substrate) or FOUP (300mm substrate) load ports compatibility. It handles various substrates for advanced packaging, including Si, glass and CCL, and accommodates sizes of 200mm and 300mm.

Building on the IVS family’s 40 years of experience in CMOS, MEMS and compound semiconductor applications, the IVS 380 system possesses the versatility to tackle overlay, CD and z-height measurements for diverse substrates and layers. It measures critical dimensions in the xy plane and the vertical z-heights of features like RDL metal lines, posts and bumps. The optics enable focus on mostly transparent materials such as photoresists and rough surfaces such as electroplated copper.

Applications

- Critical Dimension

- On Product Overlay

- Specialty

Featured Markets

3D Demo

Enter your information below and we’ll send you a unique passcode to view our IVS 3D Demo.

Do you have an IVS 380 system question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields

IVS 280 System

The IVS 280 system delivers overlay, CD and z-height metrology for 100mm-200mm wafers. It is designed to meet the challenging requirements of power, compound semi and MEMS segments.

Product Overview

The IVS 280 system has been designed for ultimate precision, tool induced shift (TIS) and throughput for 100mm to 200mm wafers, with a mean time between failure (MTBF) > 2,000 hours. The IVS 280 system provides the same capability in a system designed for overhead track handling with full capability per SEMI® standards.

Flexibility is key in compound semiconductor processes, accommodating various wafer sizes, thicknesses, and compositions, including versatile wafer handling for Si, SiC, quartz, glass, GaAs, GaN, and LiNO3 wafers.

Its robust wafer handling and navigation system requires no operator assistance during recipe execution. The IVS 280 system enables wafer size changes without hardware alterations. Recipes and data remain stable over time. The system also supports recipe transfers from older IVS platforms like the IVS 200 and IVS 220.

The demonstrated capabilities of the IVS system to perform with high precision and solid reliability set this system apart.

Applications

- Critical Dimension

- On Product Overlay

- Z-Height

Featured Markets

3D Demo

Enter your information below and we’ll send you a unique passcode to view our IVS 3D Demo.

Do you have an IVS 280 question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields

Iris™ S System

The Iris S system is a versatile platform solution for the advanced packaging and specialty market, supporting 150mm, 200mm and 300mm wafers. It provides thin and thick film, OCD and wafer bow and film stress measurements.

Product Overview

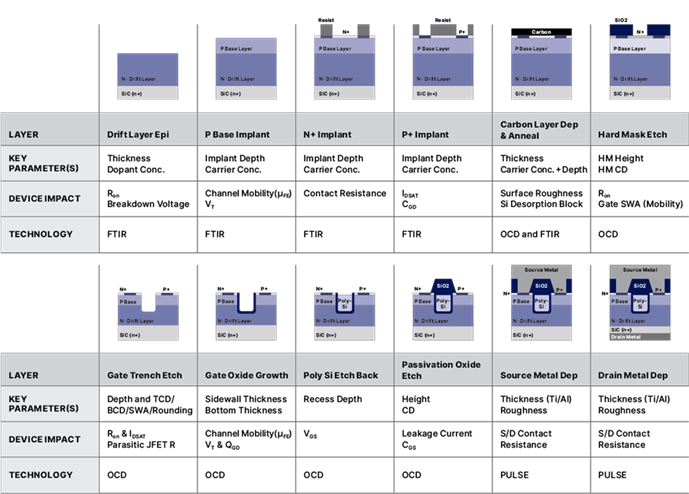

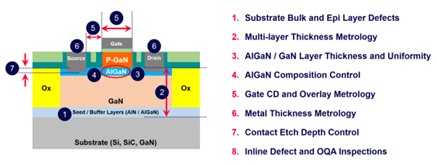

The Iris S system delivers films metrology and advanced OCD capabilities for the specialty and advanced packaging segments. With a small footprint, it handles 150mm, 200mm, and 300mm wafer sizes, including thin, thick and bonded wafers. The system supports various materials such as Si, SiC, GaN and glass, addressing device-level challenges impacting performance and yield. Leveraging Onto’s Ai Diffract™ software, the Iris S system supports the most difficult on-wafer high value problems.

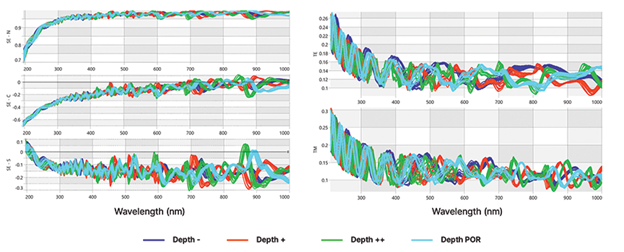

The Iris S system includes a dual-arm robot, high-precision stage, advanced pattern recognition, and high-speed focus for accurate positioning at high throughput. The dual channel optical architecture offers oblique incidence Mueller Matrix spectroscopic ellipsometry (MMSE) and normal incidence spectroscopic reflectometry (SR) in a broad wavelength range from UV to IR.

Based on Windows 10 OS and a 64-bit architecture, the Ai Diffract™ software interface and automation comply with SEMI standards. Onto’s model guided machine learning enables fast, flexible and robust film and OCD recipe setup.

Applications

- Thin, thick and ultra thick film thickness

- Trench/OCD metrology capabilities

- Optical properties and composition solutions

- Configurable for 6”, 8” and 12” wafer sizes

- High warped wafer handling and stress measurements

- Si, SiC, GaN and glass wafer handling

Featured Markets

Intelligent Line Monitoring & Control with Integrated Metrology

Enhance CMP process control with a connected metrology approach that feeds forward data from standalone OCD or films metrology to integrated metrology, connected through AI-driven analytical software. This approach, powered by advanced modeling and analysis tools, can deliver high-precision, high-throughput results—minimizing or eliminating the need for and cost of new TEM data and enabling accelerated time to solution, faster excursion detection, reduced cost and improved Cpk.

Enhancing CMP Process Control with Intelligent Line Monitoring & Integrated Metrology

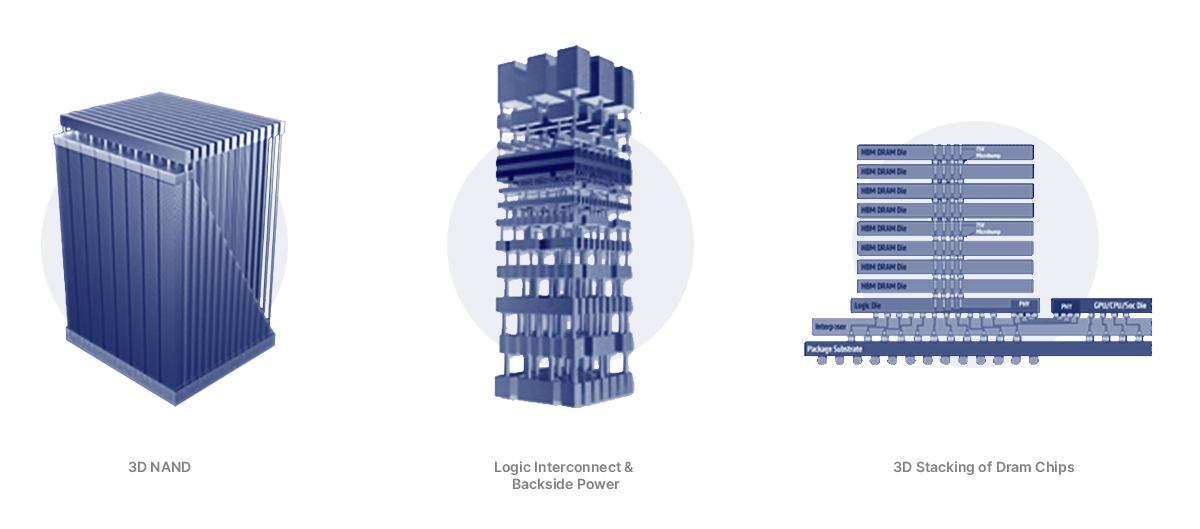

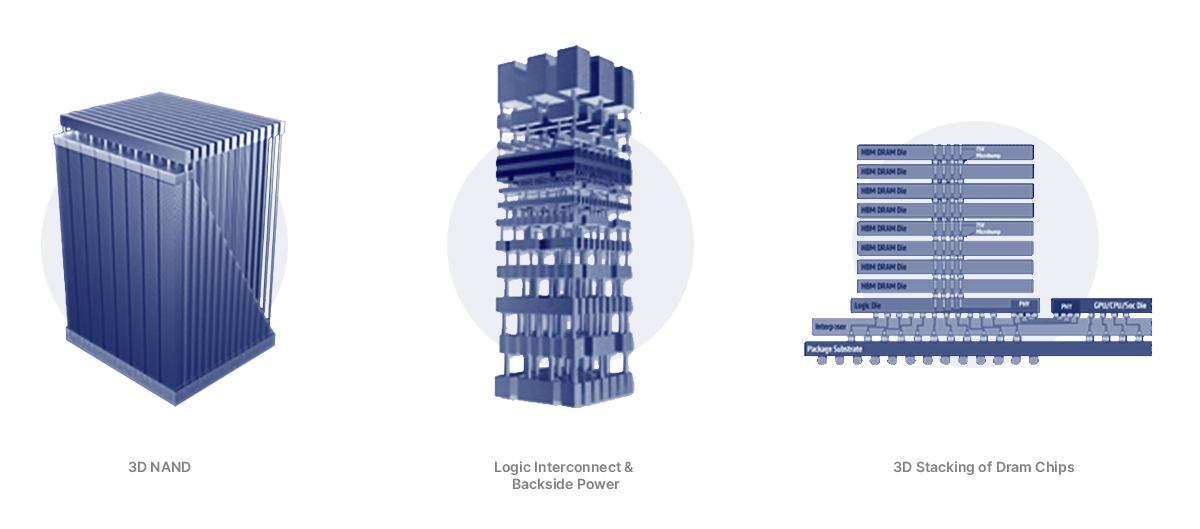

As semiconductor manufacturers push the boundaries of performance and functionality—driven by high-performance computing and AI applications—chemical mechanical planarization (CMP) processes increase in intensity complexity. New logic transistor designs, 3D NAND stacking, and DRAM integration introduce more CMP layers and tighter process windows.

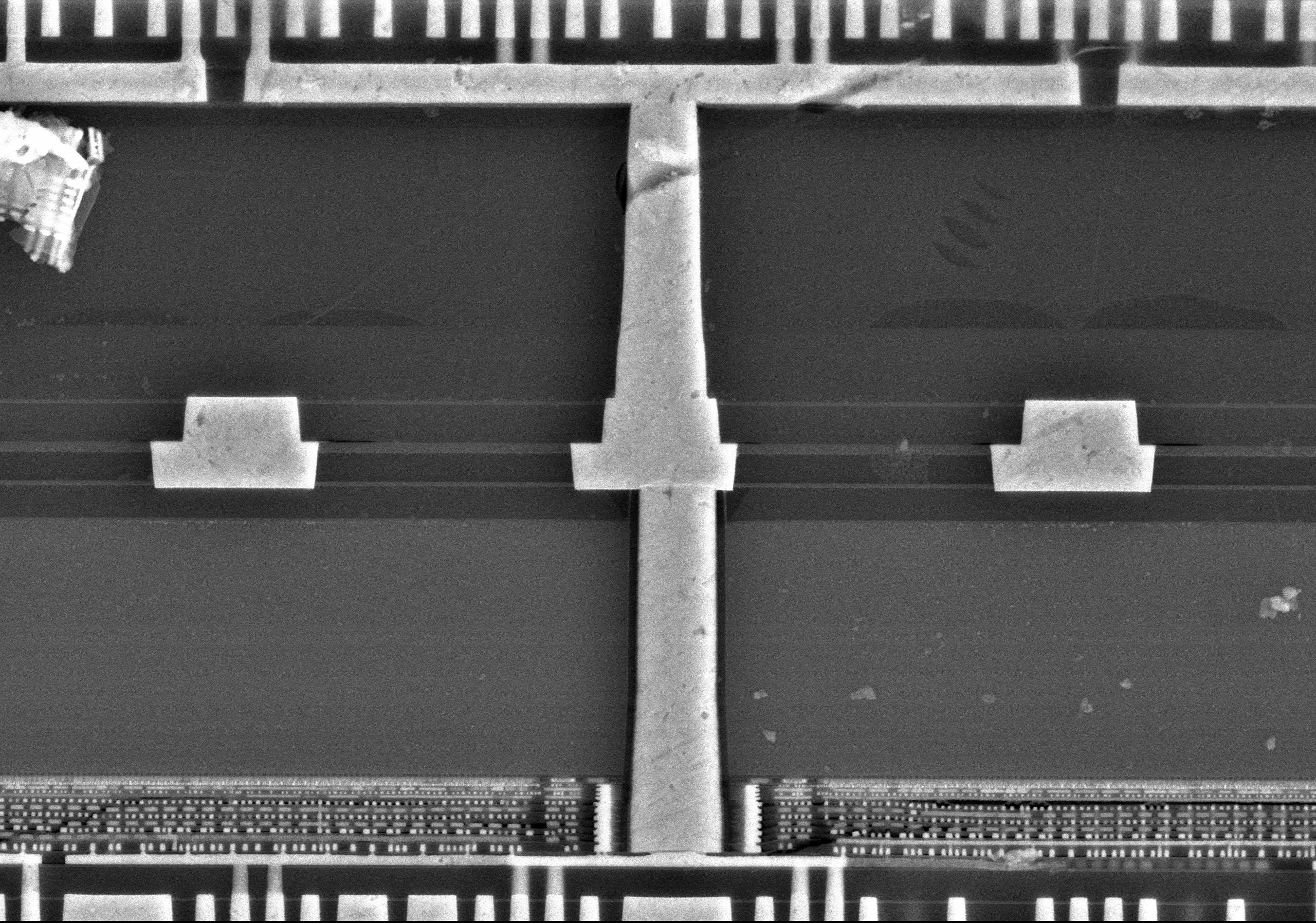

Hybrid Bonding Process Control Solution

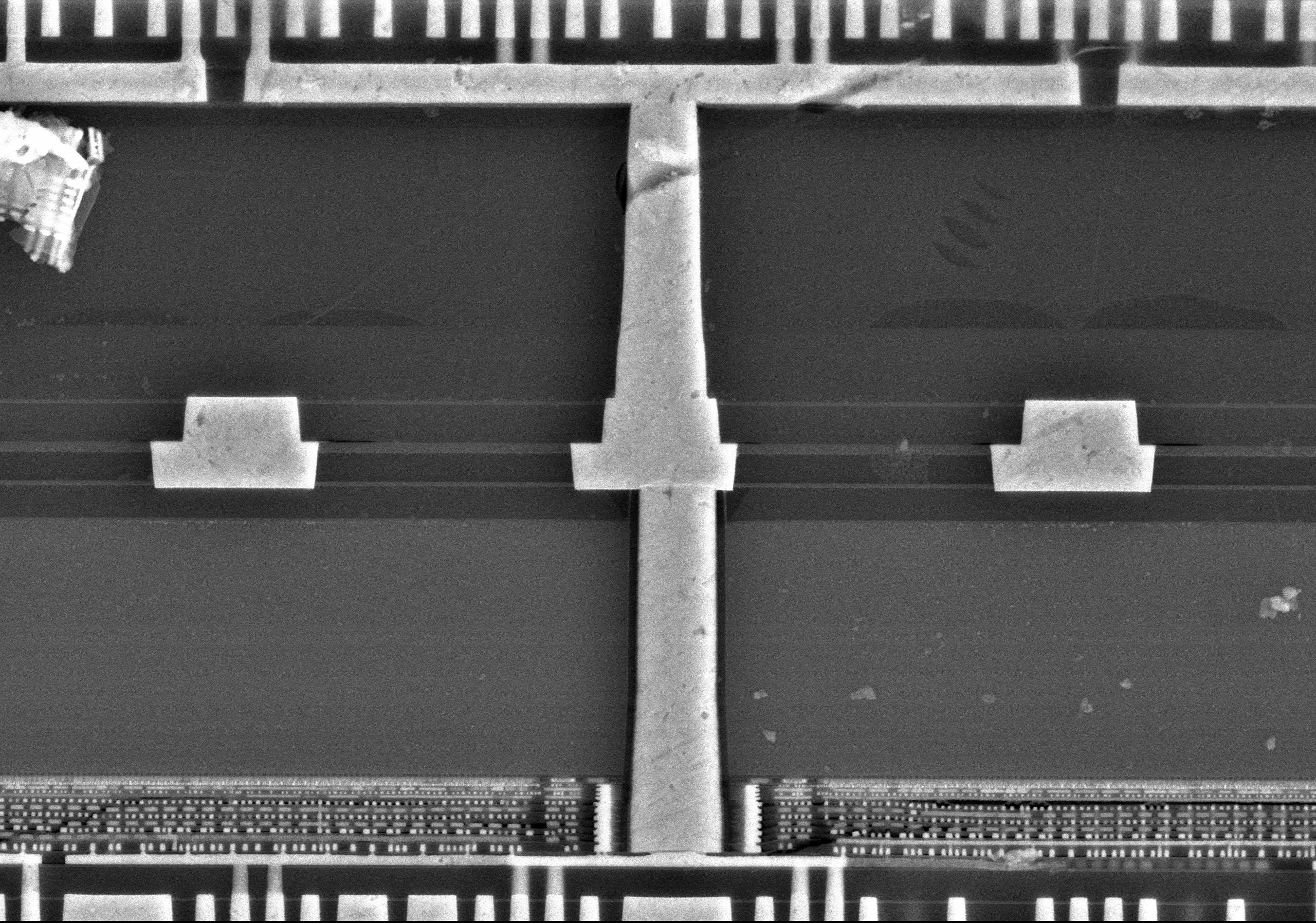

Hybrid bonding enables ultra-dense 3D memory interconnects with up to 1,000x more connections than microbumps. Achieving high yield requires stringent process control, including monitoring topography and detecting particles, cracks and voids. Measuring dishing in copper pads provides valuable insight into surface conditions. Together, these process control insights contribute to improved device reliability and performance.

Enabling In-Line Process Control for Hybrid Bonding Applications

As demand grows for high-performance computing (HPC) and AI-driven applications, manufacturers are turning to hybrid bonding to enable the ultra-dense 3D integration required for next-generation chip architectures. This advanced packaging technology presents significant process challenges. Surface preparation must be precisely controlled to eliminate particles, excess recess, and copper pad dishing, all of which can compromise bond quality. During pre-annealing, particle-induced gaps and wide bonding gaps can prevent proper wafer contact. Post-annealing, the formation of dielectric and metal voids introduces further risks to electrical performance and long-term reliability.

Do you have an Iris S system question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields

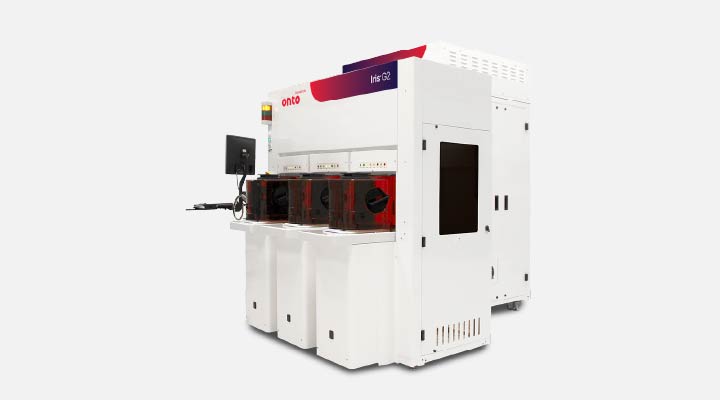

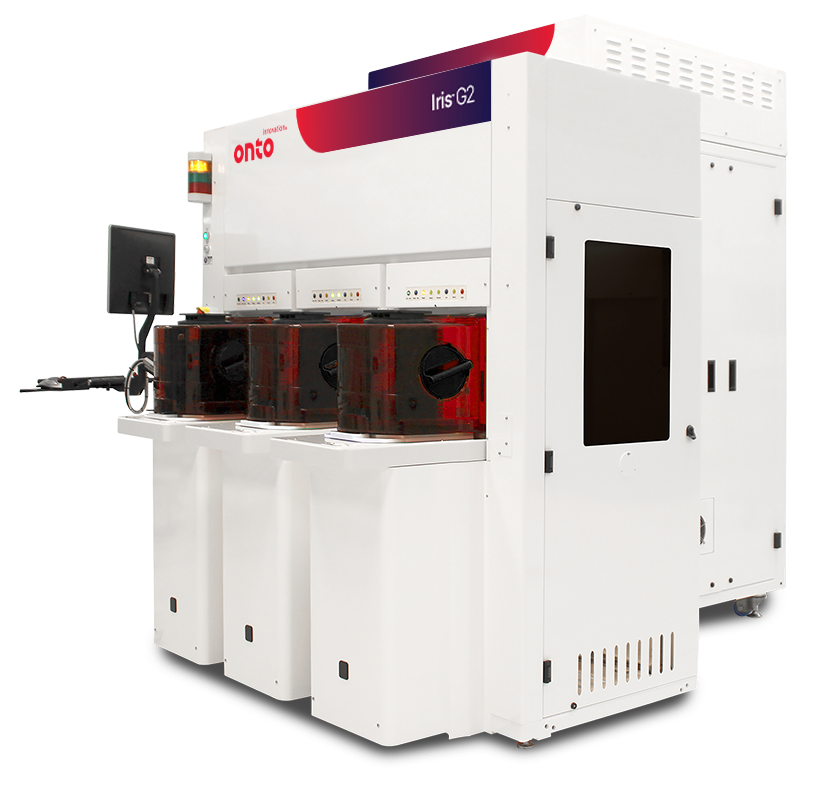

Iris™ G2 System

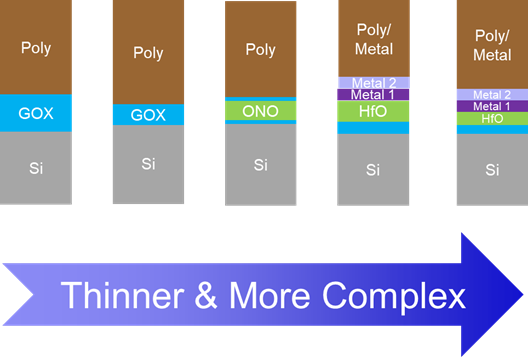

The Iris G2 system is an advanced optical metrology tool for both common and critical thin films for advanced node, mature and specialty devices, enabling manufacturers to increase transistor speed, reduce power consumption and improve reliability.

Product Overview

As semiconductor device technologies become increasingly complex, requiring thinner and more uniform films, the need for a stable, all-in-one thin film metrology solution becomes a necessity. By controlling the quality and effective thickness of gate films, the Iris G2 system supports critical device scaling and performance improvements.

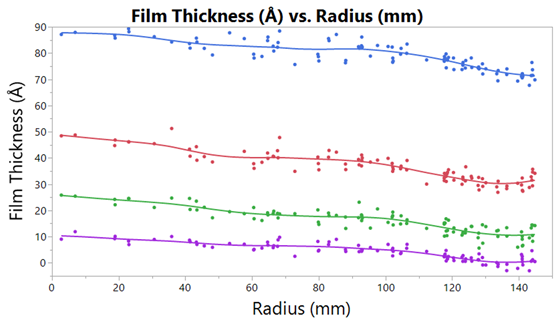

For ultra-thin multilayer films measuring 10Å to 50Å, the Iris G2 system features deep ultraviolet (DUV) spectroscopic ellipsometry (SE) for common films and coupled proprietary laser ellipsometry technologies for critical films, providing customers with the flexibility to optimize cost of ownership, better stability, and ease of operation in a versatile tool for specialty, mature and advanced logic and memory processes.

Additionally, a single platform simplifies fleet management and fab operations while reducing overall capital investment.

Applications

- Critical film measurement

- Common film measurement

- 2D and 3D OCD measurement

- Wafer bow, warp, and film stress

Intelligent Line Monitoring & Control with Integrated Metrology

Enhance CMP process control with a connected metrology approach that feeds forward data from standalone OCD or films metrology to integrated metrology, connected through AI-driven analytical software. This approach, powered by advanced modeling and analysis tools, can deliver high-precision, high-throughput results—minimizing or eliminating the need for and cost of new TEM data and enabling accelerated time to solution, faster excursion detection, reduced cost and improved Cpk.

Enhancing CMP Process Control with Intelligent Line Monitoring & Integrated Metrology

As semiconductor manufacturers push the boundaries of performance and functionality—driven by high-performance computing and AI applications—chemical mechanical planarization (CMP) processes increase in intensity complexity. New logic transistor designs, 3D NAND stacking, and DRAM integration introduce more CMP layers and tighter process windows.

Do you have an Iris G2 system question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields

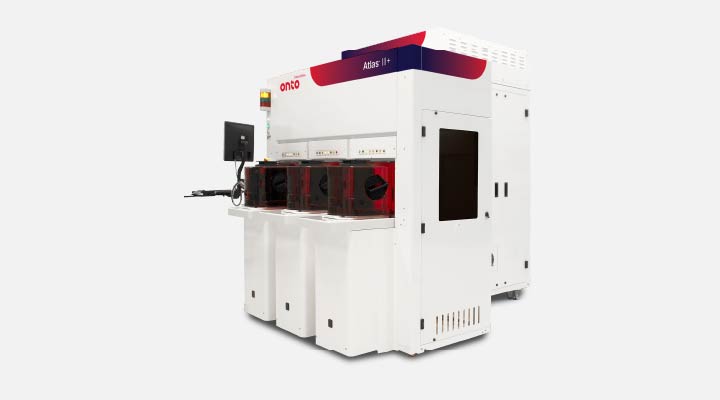

IMPULSE®+ System

The IMPULSE+ system is designed to deliver film measurement, fidelity and productivity in the CMP process module. Available as an integrated or standalone platform, it offers high sensitivity and accuracy.

Product Overview

An integrated metrology standard, the IMPULSE+ system offers high sensitivity and accuracy to CMP process excursions and enables device makers to establish APC control with high-accuracy feedback. The IMPULSE+ system works in conjunction with the Atlas® platform, facilitating cross-module process optimization and comprehensive fab-wide process control.

Based on a common optical design derived from our stand-alone Atlas® platform, the IMPULSE+ system shares superior deep ultraviolet (DUV) optics. This unique ecosystem can be leveraged to improve signal to noise ratio by applying spectra feedforward from the Atlas platform, further enhanced by AI-driven machine analytics. This combination affords CMP process engineers a potent arsenal of capability to manage excursions and drive process improvement (Cpk.).

The IMPULSE+ system is widely adopted across key steps in DRAM, 3D-NAND, CMOS image sensor and foundry/logic device manufacturing. challenging to measure.

Applications

- CMP

Intelligent Line Monitoring & Control with Integrated Metrology

Enhance CMP process control with a connected metrology approach that feeds forward data from standalone OCD or films metrology to integrated metrology, connected through AI-driven analytical software. This approach, powered by advanced modeling and analysis tools, can deliver high-precision, high-throughput results—minimizing or eliminating the need for and cost of new TEM data and enabling accelerated time to solution, faster excursion detection, reduced cost and improved Cpk.

Enhancing CMP Process Control with Intelligent Line Monitoring & Integrated Metrology

As semiconductor manufacturers push the boundaries of performance and functionality—driven by high-performance computing and AI applications—chemical mechanical planarization (CMP) processes increase in intensity complexity. New logic transistor designs, 3D NAND stacking, and DRAM integration introduce more CMP layers and tighter process windows.

Do you have an IMPULSE+ system question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields

IMPULSE® V System

The IMPULSE V system helps to advance CMP processing with enhanced wavefront technology and AI-driven analytics, delivering over 2X precision improvement and faster solutions, crucial for next-gen semiconductor manufacturing demands.

Product Overview

As wafer uniformity requirements tighten and vertical scaling increases, the need for CMP processing grows across market segments. Logic introduces new transistor designs and materials, DRAM incorporates new materials and process steps to planarize, and 3D NAND adds more decks, stacks and tiers.

The IMPULSE V system, available as an integrated or standalone platform, enhances film measurement fidelity and productivity for the CMP process module. With deep ultraviolet (DUV) optics and AI-driven machine analytics derived from our Atlas® platform, it works in conjunction with the Atlas® platform to provide CMP process engineers the capability to manage excursions and drive process improvement (Cpk.).

Advanced wavefront technology suppresses previous layer noise in complex structures. It provides feedback to improve long term repeatability. Designed for higher sampling, in-die/on-device and wafer edge measurements, the system offers improved reliability, higher throughput and over 2X precision improvement compared to the previous generation. Onboard AI-driven machine learning uses a signal-to-noise ratio for faster time-to-solution, addressing layers that were previously challenging to measure.

Applications

- CMP

Intelligent Line Monitoring & Control with Integrated Metrology

Enhance CMP process control with a connected metrology approach that feeds forward data from standalone OCD or films metrology to integrated metrology, connected through AI-driven analytical software. This approach, powered by advanced modeling and analysis tools, can deliver high-precision, high-throughput results—minimizing or eliminating the need for and cost of new TEM data and enabling accelerated time to solution, faster excursion detection, reduced cost and improved Cpk.

Enhancing CMP Process Control with Intelligent Line Monitoring & Integrated Metrology

As semiconductor manufacturers push the boundaries of performance and functionality—driven by high-performance computing and AI applications—chemical mechanical planarization (CMP) processes increase in intensity complexity. New logic transistor designs, 3D NAND stacking, and DRAM integration introduce more CMP layers and tighter process windows.

Hybrid Bonding Process Control Solution

Hybrid bonding enables ultra-dense 3D memory interconnects with up to 1,000x more connections than microbumps. Achieving high yield requires stringent process control, including monitoring topography and detecting particles, cracks and voids. Measuring dishing in copper pads provides valuable insight into surface conditions. Together, these process control insights contribute to improved device reliability and performance.

Enabling In-Line Process Control for Hybrid Bonding Applications

As demand grows for high-performance computing (HPC) and AI-driven applications, manufacturers are turning to hybrid bonding to enable the ultra-dense 3D integration required for next-generation chip architectures. This advanced packaging technology presents significant process challenges. Surface preparation must be precisely controlled to eliminate particles, excess recess, and copper pad dishing, all of which can compromise bond quality. During pre-annealing, particle-induced gaps and wide bonding gaps can prevent proper wafer contact. Post-annealing, the formation of dielectric and metal voids introduces further risks to electrical performance and long-term reliability.

Do you have an IMPULSE V system question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields