FAaST® CV/IV System

The FAaST system is a versatile, non-contact electrical metrology platform, with an option to combine micro and macro corona-Kelvin technologies together with digital surface photovoltage (SPV). It enables high-resolution dielectric and interface measurements across a wide range of dielectric materials, supporting both R&D and high volume manufacturing.

Product Overview

The primary application of non-contact CV metrology is monitoring dielectric properties during IC manufacturing. Unlike conventional electrical measurements, it requires no sample preparation, eliminating the need for MOS capacitor structures. This reduces metrology cost and enables fast data feedback in both R&D and manufacturing environments.

The corona-Kelvin method uses a corona discharge in air to deposit an electric charge (DQC) on the wafer surface. A vibrating Kelvin-probe then measures the resulting surface voltage (V), enabling determination of the differential capacitance (C= DQC/DV). By monitoring surface voltage in both dark and illuminated conditions, the system separates two key components: dielectric voltage (VD) and semiconductor surface potential (VSB), enabling determination of flat band voltage (VFB).

Analysis of the resulting charge-voltage data yields electrical parameters, including trap density (Dit), flat band voltage (Vfb), dielectric charge (Qtot), dielectric capacitance (CD), Equivalent Oxide Thickness (EOT), leakage current, and tunneling characteristics.

Applications

- Plasma damage monitoring

- Residual charge and non-visual defect inspection

- Diffusion furnace oxide and interface characterization

- High-K and low-K dielectric capacitance

- Mobile ion mapping

- Charge trapping and hysteresis

Featured Markets

Do you have a FAaST CV/IV system question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields

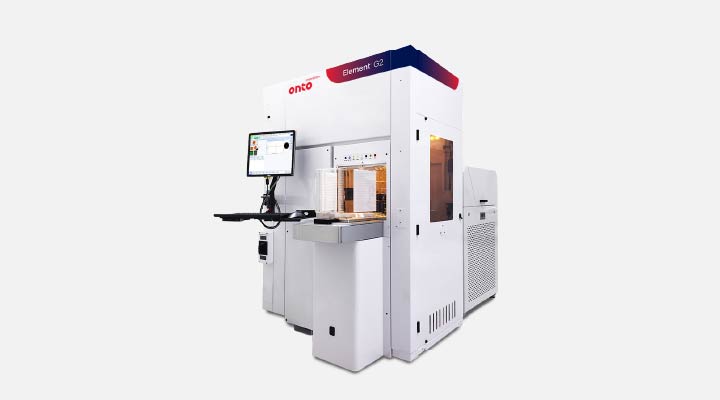

MBIR System

The MBIR system is a revolutionary in-line, non-destructive infrared reflectometry system that enables critical process control of high aspect ratio structures, films and epitaxial structures. It meets the needs of leading-edge customers with its high speed and process coverage.

Product Overview

As more high aspect ratio processes are used in multiple industry segments, there are metrology needs for monitoring of related processes, including dimensions and properties of carbon film hard masks and etched 3D structures.

The MBIR system delivers high-throughput, low COO, non-contact, non-destructive measurements of dimensions and uniformity of layers and etched structures used in integrated circuit manufacturing. The small spot size makes the tool suitable for measurements of scribe line test structures as in-line process control. The unique technology and analysis capability simplifies system calibration requirements and removes the effect of substrate variations for key layer measurements.

While the software contains advanced features for measurement recipe and analysis model creation, it has a user-friendly interface and implementation that allows the fab customers to create and manage the recipe system for MBIR tool fleets.

Thickness map from amorphous carbon film

Applications

- Carbon hardmask used on V-NAND devices and test wafers

- Deep trench etch for CIS and analog device chips

- Doping monitoring of SiGeB and SiP materials

- Film composition characterization

- On-device and blanket wafer materials characterization for EPI process

Featured Markets

Do you have a MBIR system question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields

FAaST® Digital SPV System

The FAaST Digital SPV system provides a fast, non-contact, and preparation-free method for full wafer imaging of contamination in silicon. High resolution maps of diffusion length and iron (Fe) concentration are generated in minutes, setting the industry standard for precision and sensitivity in Fe contamination control, reaching the E7 cm-3 range.

Product Overview

There is no disputing the detrimental effect of metallic contamination on the integrity of the critical gate oxide used in integrated circuits. During high temperature processing, contamination in the silicon wafer often precipitates at the Si/dielectric interface or segregates into the dielectric—both scenarios can cause premature device failure and reduced yield. As device dimensions shrink, the tolerance for contamination decreases, requiring ever-lower background levels of metals like iron (Fe). Over the past 25 years, the IC industry has reduced typical Fe concentrations by more than three orders of magnitude, yet further reduction is essential, especially for applications like CMOS image sensors.

The FAaST Digital SPV system addresses this challenge with industry-leading sensitivity and speed. It provides a fast, non-contact, and preparation-free method for full-wafer imaging of contamination. High-resolution maps of minority carrier diffusion length and Fe concentration are generated in minutes, enabling fabs to detect and control contamination at levels as low as the E7 cm⁻³ range.

Figure 1. Typical background Fe concentration in new IC Fablines (blue) and the state-of-the-art SPV detection limit (red)

Applications

- Ingot qualification

- Outgoing / incoming polished wafers

- Epitaxy

- Cleaning

- Diffusion furnace monitoring

- Rapid thermal anneal

Featured Markets

Do you have a FAaST Digital SPV system question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields

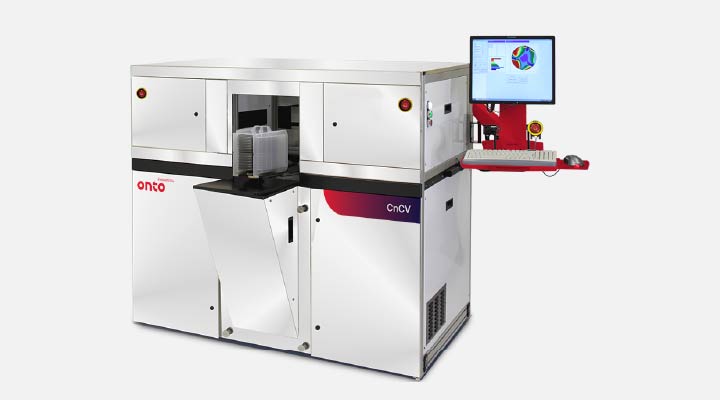

CnCV® System

The CnCV system enables wafer-level characterization of WBG materials without test device fabrication, reducing time and cost. As a mercury-free alternative to MCV, it eliminates contamination concerns. The enhanced Kinetic CV mode with UV-assisted corona charge neutralization achieves high throughput and precision for fast, reliable process control.

Product Overview

The CnCV system utilizes a novel constant surface potential corona charging, which enables the precision required over a large voltage range. The patented technology includes charge- and photo-assisted modes, especially suited for speed and precision on WBG materials and structures, including SiC, Ga2O3, GaN, and AlGaN/GaN HEMT. Additionally, Corona-Kelvin characterization includes electrical properties of dielectrics and interfaces of films on SiC and GaN epi layers. An automated top-side edge contact (TSEC) is also available enabling characterization of WBG on insulating/semi-insulating substrates. Automated bias-temperature stress (BTS) measurements are also available with the CnCV system, providing a fast, noncontact way to quantify the reliability of passivated SiC and GaN.

Beyond typical CV type parameters, the full wafer corona approach allows for QUAD (quality, uniformity, and defect) mapping. The electrical defect imaging, QUAD-EDI, mode is especially designed for SiC. It provides a unique means for quick screening of epi electrical defectivity enabling improvement in device yield prediction.

Figure 1. QUAD-EDI Map on final metallized device wafer after Merged Schottky PiN diode fabrication identifying failed dies.

Applications

- Non-contact epi dopant depth profiling in WBG materials

- AlGaN\GaN HEMT measurements (pinch off voltage & 2DEG sheet charge)

- Dielectric and interface characterization electrical defect imaging in SiC for yield prediction

- Bias-temperature stress (BTS) instability measurements on passivated WBG materials

Featured Markets

Do you have a CnCV system question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields

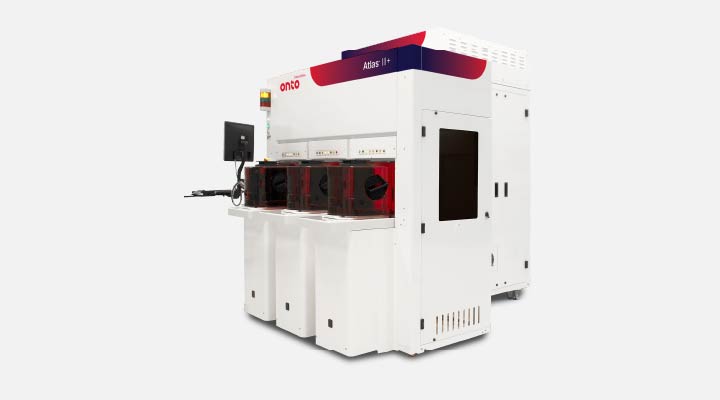

Atlas® G6 System

The Atlas G6 system is an OCD and thin film metrology tool engineered for the most advanced logic and memory devices. Designed to meet the demands of next-generation AI applications and beyond, it delivers enhanced optics, AI-driven recipe development, and tighter tool matching for superior process control.

Product Overview

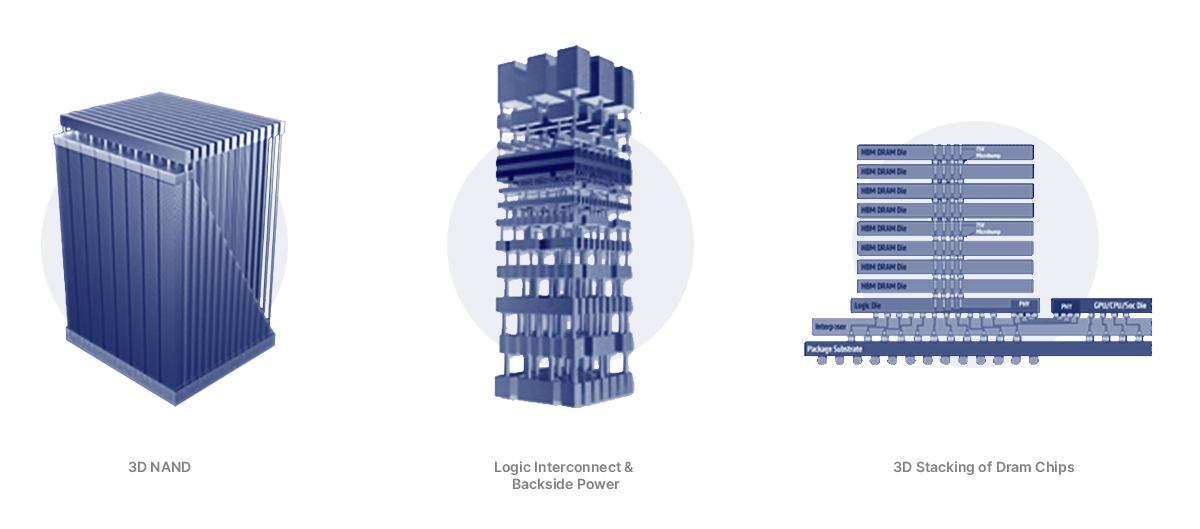

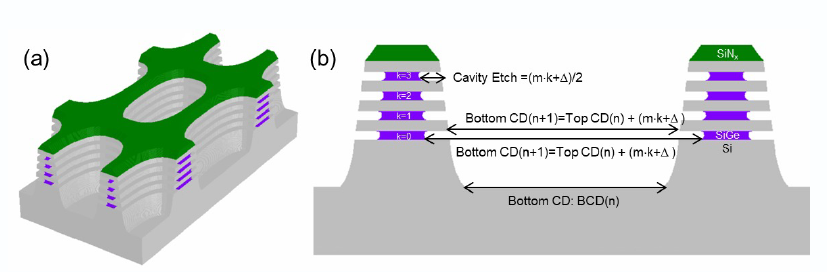

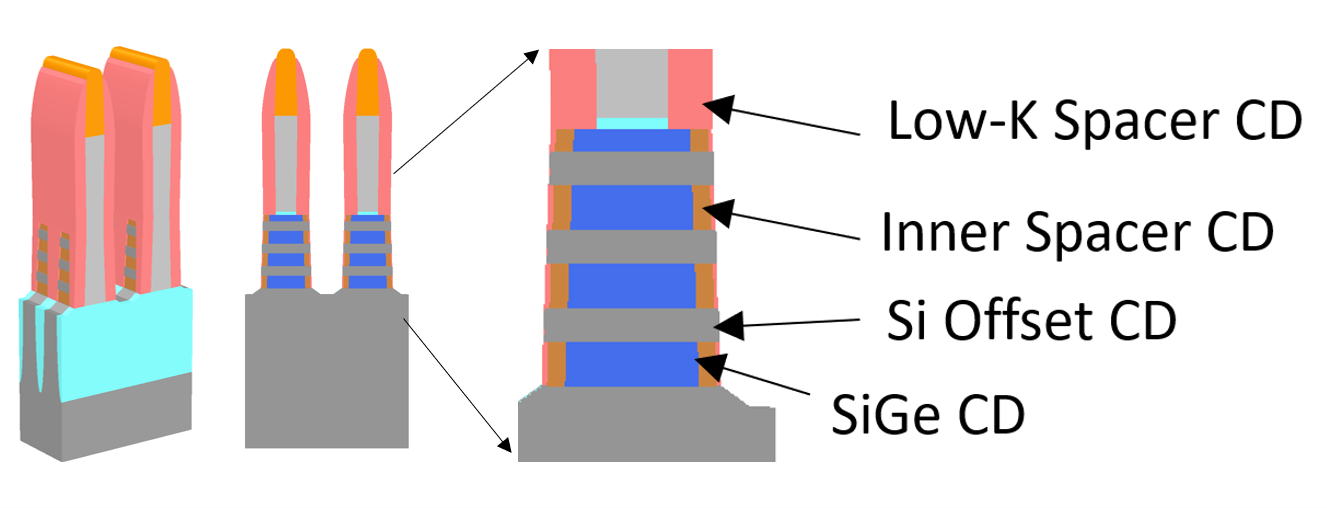

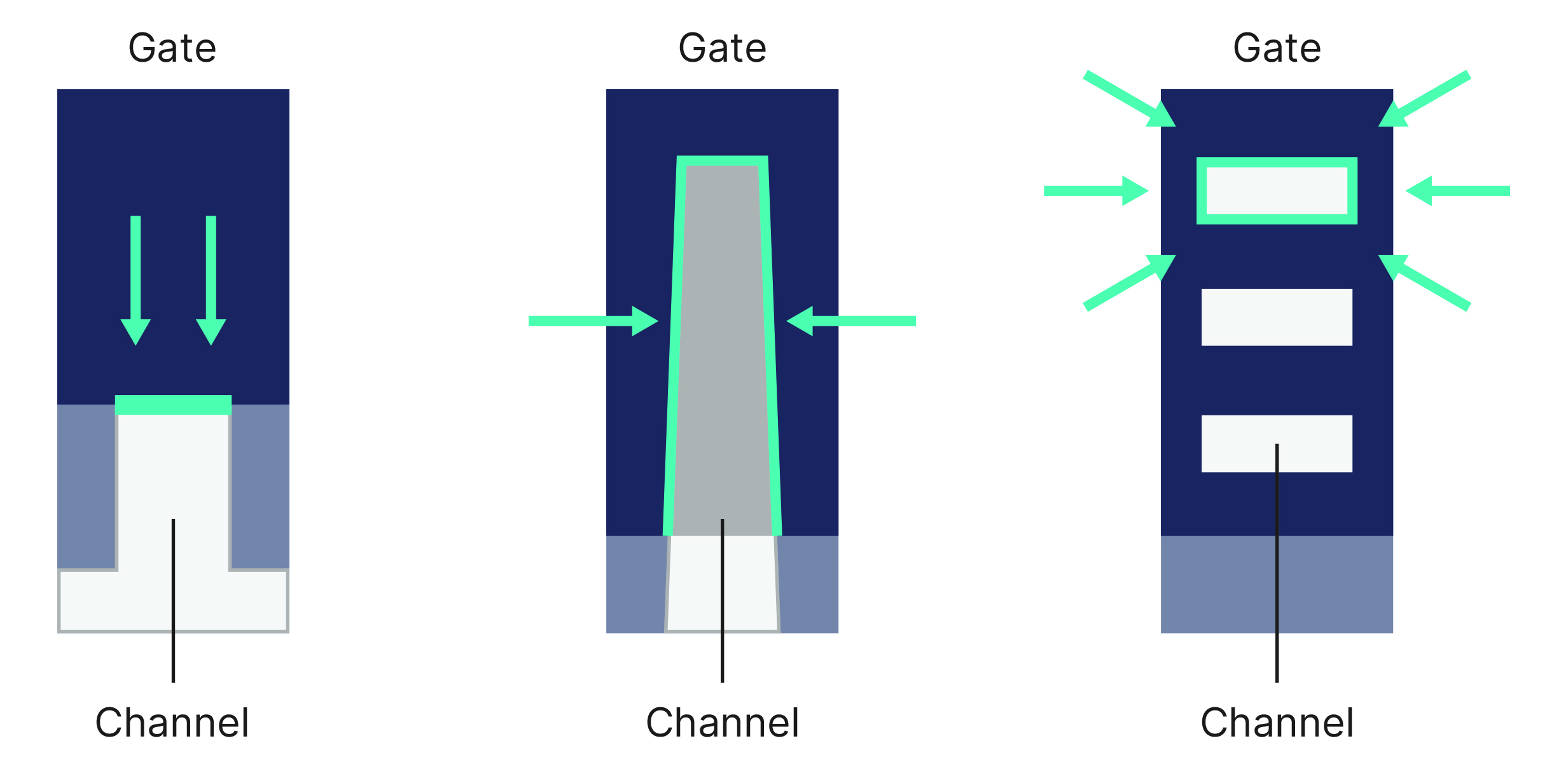

As semiconductor manufacturers push into next-generation GAA nodes and next-gen HBM and vertical DRAM architectures, process control requirements are tightening. Smaller nanosheet structures and denser DRAM cells demand higher measurement precision, faster recipe development, and tighter tool-to-tool matching.

The Atlas® G6 system is engineered to meet these challenges with a new optics design that improves signal-to-noise ratio, spectral stability, and measurement precision. Enhanced software algorithms and data management tools deliver better fleet-wide spectra matching, while a new data channel and next-generation model-guided machine learning in Ai Diffract™ software enable faster, more robust recipe development. A smaller optical spot size ensures accurate measurements on today’s most compact DRAM structures.

Fully integrated with Onto Innovation’s Discover® ecosystem, the Atlas G6 system empowers fabs with predictive process control and smart manufacturing capabilities—accelerating yield and time to market for the industry’s most advanced devices.

Applications

- OCD for litho, etch, CVD & CMP process in all device segments

- Local variation

- Asymmetry and tilt

- Common and critical films

- Stress & wafer warpage

Do you have an Atlas G6 system question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields

OCD Solutions

A suite of OCD modeling software and computing hardware that enables the full capability and connectivity across all Onto OCD and thin film metrology systems, including Atlas, Aspect, Iris and IMPULSE systems.

Product Overview

Onto Innovation’s OCD technology offers powerful modeling and computing packages to support various phases of film and OCD measurement setup, data management, and fleet management. These capabilities include model building, runtime data analysis, system calibration, data analytics, data connectivity and management, spectrum management and fleet matching.

Onto OCD solutions consist of several modeling and computing components, including Ai Diffract™ modeling software, runtime onboard computer, offline modeler, offline model building clusters, and recipe & data management server. Each component seamlessly extends OCD capabilities to Onto’s standalone and integrated metrology systems, providing end-to-end capabilities from offline recipe support and development to fab-wide networking and connectivity for easy fleet management.

Learn more about each component below.

Featured Markets

Ai Diffract™ Software

AI-guided OCD modeling and analysis software for high accuracy in-line optical metrology and offline recipe development

Ai Diffract software is a powerful modeling, visualization and analysis software with an intuitive 3D modeling interface to simplify the building and visualization of today’s most complex semiconductor devices. It offers OCD modeling and advanced machine learning capabilities, next-generation real-time regression, offline sensitivity analysis tools and comprehensive GUI and structure input for true multi-variant modeling. Ai Diffract software’s proprietary fitting algorithms enable fast and accurate calculations for signal processing, helping ensure high fidelity model-based measurements. Automation features for spectral fitting, recipe optimization, and sensitivity analysis offer great user productivity. The first-in-market AI-guided engine synergizes physics-based modeling and machine learning to deliver the most robust solution with quick time to solution.

Ai Diffract Modeler is the offline analytical engine that allows users to create and edit recipes offline. It supports multiple users and can connect to Ai Diffract cluster for high intensity computing.

Ai Diffract Onboard is the on-tool runtime engine that maximizes tool throughput for complex use cases. It ensures rapid analysis without interfering with system operation or impacting throughput.

Ai Diffract Cluster is an enterprise scale computing server deployed for offline recipe development or in-line real-time regression. Optimized to support the workload of Ai Diffract software analysis, it scales based on fleet size, recipe numbers, and computing intensity.

Recipe Distribution Server (RDS) / Nexus Servers is a fab-wide networking and server system for fleet management and connectivity. RDS/Nexus servers provide connectivity and support to Ai Diffract recipe management and distribution, data/spectrum feed-forward and feedback, spectrum management, and fleet management.

Do you have an OCD solutions question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields