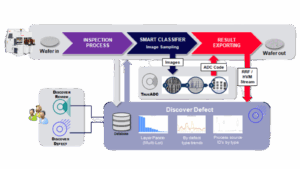

Inspection Tool Productivity Software

The native integration of the Discover software platform boosts tool throughput and enhances inspection quality by capturing more defects of interest. It provides a complete reduced review solution utilizing advanced machine learning (ML) and artificial intelligence (AI) technologies, customized to meet unique customer needs.

Enhance Your Inspection & Metrology Experience with Onto Software

Optimized Image Capture for Inspection Tools

Discover software enhances inspection quality and tool throughput by optimizing the image capture sample plan.

AI-Powered Automatic Defect Classification (TrueADC Software)

Integrated AI-based classification improves device quality and yield, driving fab efficiency and productivity.

Streamlined Review Software

Reduced review best practices improve operator productivity, enhance engineering review quality, and shorten review time.

Advanced Defect Analytics

Comprehensive inline wafer/panel monitoring enables automatic alarm notifications, detailed reports and Out-of-Control Action Plans (OCAPs).

Defect Source Analysis

Enables actionable process feedback to improve manufacturing outcomes.

Automated Business Analysis with Report Server

Boosts engineering productivity by up to 25% and supports multiple production report formats.

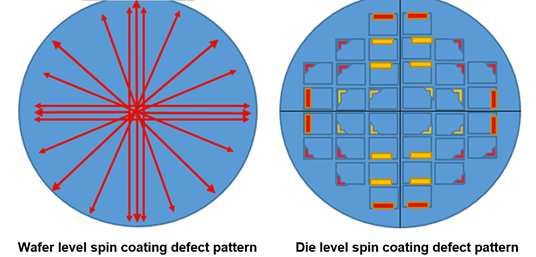

Machine Learning-Based Pattern Detection

The Discover Patterns software module proactively identifies wafer-level systematic yield-limiting issues and classifies them for analytics, enabling both process feedback and feedforward.

Centralized Defect & Metrology Management

Built on a scalable Big Data and high-availability architecture, this solution supports advanced applications such as high volume manufacturing (HVM) bump metrology, capable of handling wafers with over 100 million bumps.

Do you have an Inspection Tool Productivity Software question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields

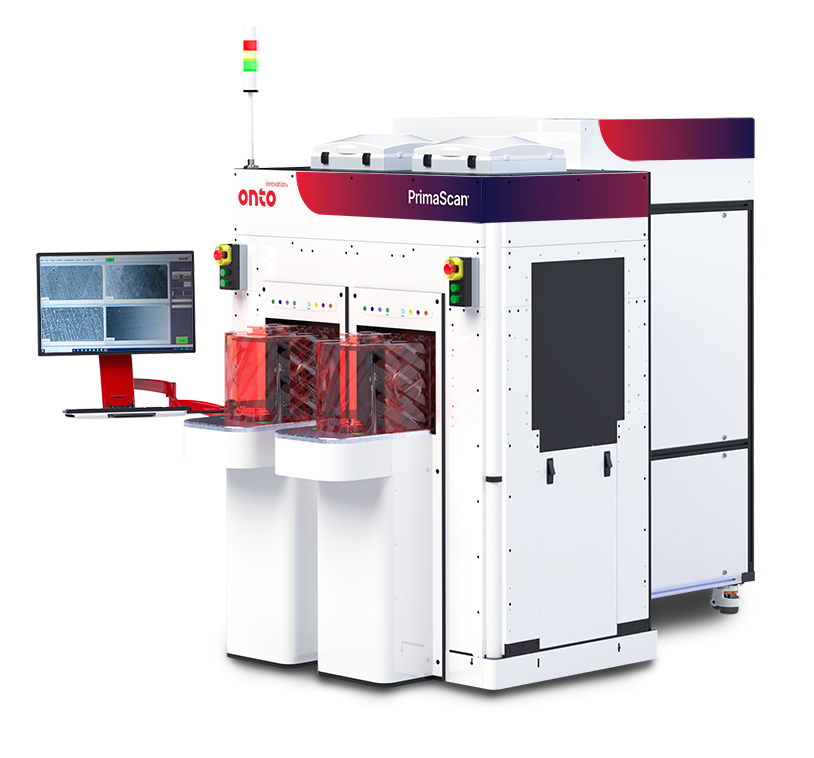

PrimaScan™ System

The PrimaScan wafer defect inspection system delivers a flexible, high sensitivity solution at the lowest cost of ownership per pass.

Product Overview

The PrimaScan system utilizes laser scatterometry and imaging techniques leveraging proprietary optics and sensing technologies for reliable inspection of nanometer sized defects on a variety of opaque and transparent/semi-transparent substrates suitable for either R&D or high-volume manufacturing environments. With multiple detection channels, the system can detect, measure, characterize and image surface particles, scratches, pits, bumps, surface contamination, film or bulk wafer stress, voids/inclusions, including chips and cracks at the wafer edge.

The PrimaScan system addresses challenges in both incoming wafer quality control and in inline process monitoring. Capable of handling multiple substrate materials, it uniquely addresses inline process defect and contamination monitoring in wafer-based production environments.

Designed with versatility in mind the PrimaScan system can handle a variety of wafer sizes and substrate types

Applications

- Opaque or transparent wafer incoming quality (ICQ) inspection

- Process monitor wafer particle and contamination inspection

- Unpatterned blanket photoresist, dielectric or metallic coated wafer defect inspection

- Subsurface defectivity inspection for transparent and semi-transparent films and substrates

- Glass carrier wafer defect and contamination inspection for advanced packaging

- Glass wafer defect and contamination inspection for microfluidics, microlens arrays for AR/VR/MR, flat optics, etc.

Do you have a PrimaScan system question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields

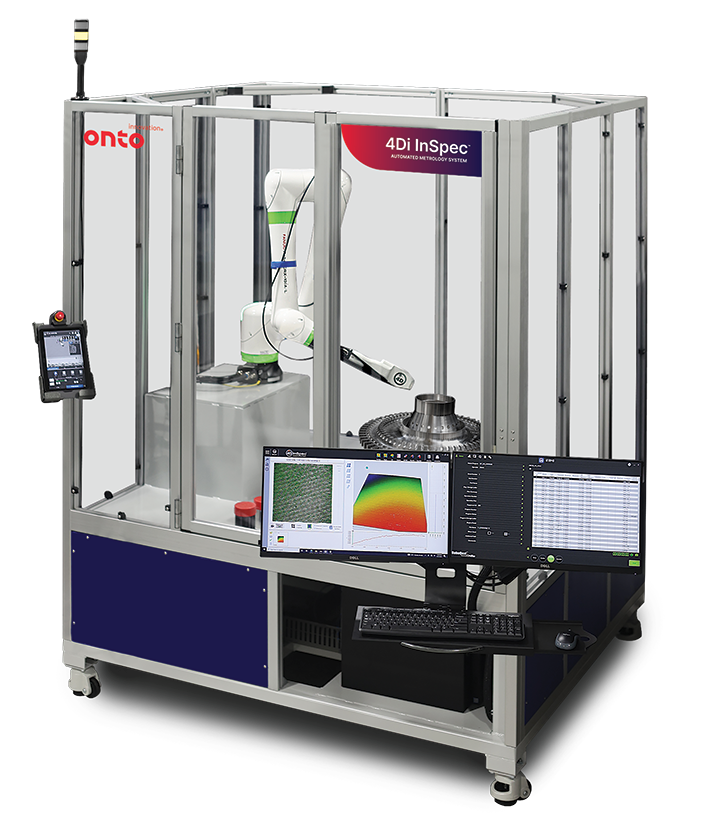

4Di InSpec Automated Measurement System (AMS)

The 4Di InSpec AMS qualifies features and defects on complex geometries and in difficult-to-reach locations – hundreds of times faster than manual inspection.

Product Overview

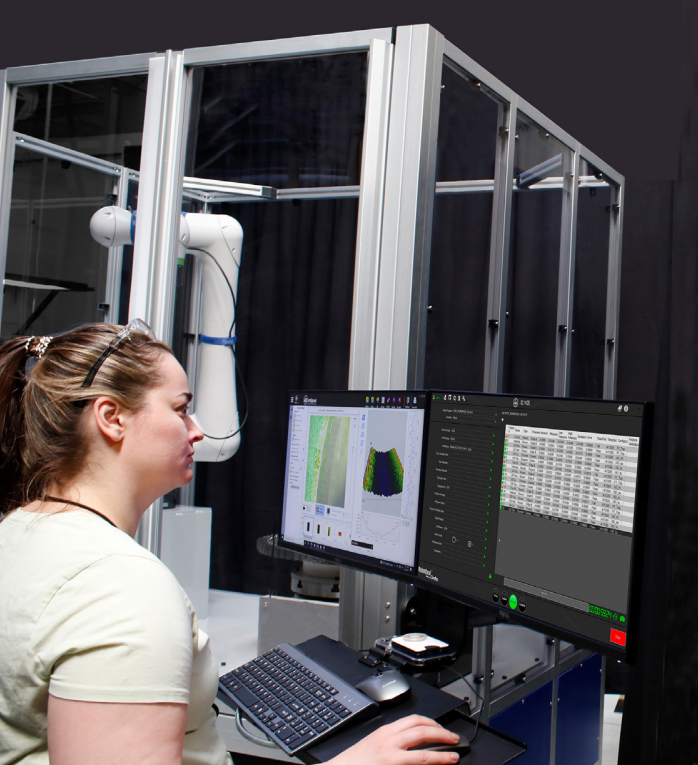

The 4Di InSpec Automated Measurement System is a non-contact optical surface gauge, either the 4D InSpec or 4D InSpec XL, integrated with a choice of collaborative robots, an optional rotary table and a safety cell for rapid production inspection.

This fully automated 3D optical system can measure dozens of edge break features, chamfers, and radii in minutes, vastly improving throughput and driving down inspection costs.

Designed as a turnkey cell for quality control, it is ideal for precision machined components such as turbine blades and rotors, air foils, high pressure compressor blades, blisks and dovetails. The high resolution system can measure in any orientation, on curved surfaces, over large and complex geometries, and in tight spaces or blind locations.

The 4Di InSpec AMS accurately captures complex feature dimensions, enabling more precise part disposition. Its rapid measurement capabilities reduce inspection queuing times, while the ability to measure at multiple locations in the same timeframe ensures part quality.

Applications

- Pits and scratches

- Nicks, dents and bumps

- Edge break, radii and chamfers

- Shot peening and part marking

- Corrosion

4Di InSpec® Surface Gauge

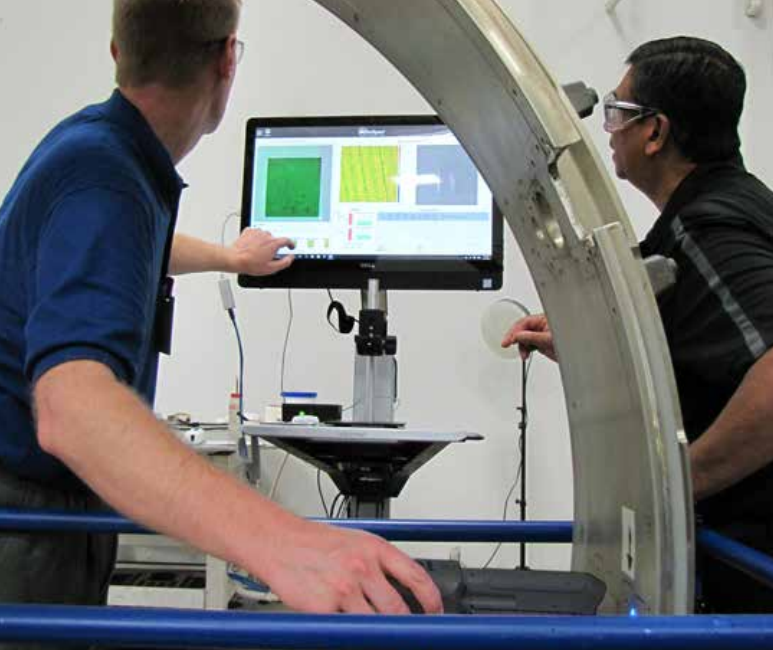

The 4Di InSpec surface gauge is a ground-breaking 3D optical gauge that enables high-resolution, non-contact surface defect and feature measurements right on the shop floor.

Product Overview

The 4Di InSpec optical surface gauge is the first handheld precision instrument designed for non-contact surface defect measurement. With micrometer-level resolution, portability, affordability and ease-of-use, the 4Di InSpec surface gauge brings high resolution 3D surface measurement where it’s needed: on the factory floor, in machine shops, and in field service applications.

This surface gauge provides 3D surface measurements to instantly quantify defects and features up to 100 mils (2,540 micrometers) deep. Without the need for replication, it can measure large components of varying complex geometries directly. It is adaptable for handheld use, workstation setups, or robotic operation with optional accessories to meet specific customer challenges.

Even with its incredible precision and extensive analysis capabilities, its ease of use allows non-experts to take measurements after just minutes of training.

Applications

- Pits and scratches

- Nicks, dents and bumps

- Edge break, radii and chamfers

- Shot peening and part marking

- Corrosion

Featured Markets

PrecisionWoRx® VX4 System

The PrecisionWoRx VX4 System is designed to provide accurate and repeatable performance through enhanced testing of the latest probe card technologies with tighter pitches, smaller pads and higher pin counts.

Product Overview

The PrecisionWoRx VX4 System gives test facilities and probe card manufacturers the ability to confidently test tighter pitches and smaller probe tips. The system can be configured to meet specific requirements for a variety of probe card technologies. For processes using cards with very small probe tips, the system’s high-resolution optics deliver a detailed field-of-view for high accuracy and repeatability. Proprietary image-processing recipes control over 30 imaging parameters for enhanced testing of most probe tip geometries in use today.

The PrecisionWoRx VX4 System improves overall cost of ownership with faster test times for common tests, including leakage, planarity, alignment, contact resistance, probe force and wire checker. Its sophisticated electrical discharge management capability maintains 1-volt continuity to the probe during electrical testing. Productivity-enhanced routines for automated testing of failed probes and a wide variety of checkplates suit an extensive range of process and technology requirements. The system provides support for the most complex probe card technologies.

Applications

- Various probe tips from 5 µm up to 250 µm diameter

- Z force up to 200 KG

- Pin counts >100,000 probes

- Direct dock probe card capabilities

- Probe card relay and solid-state switching

- Membrane probe cards

Featured Markets

Do you have a PrecisionWoRx VX4 system question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields

NSX® 330 System

The NSX 330 system offers advanced macro inspection for a wide range of defect sizes at high throughput, with optional 3D metrology integration.

Product Overview

The NSX 330 system features robust platform technology with high-acceleration staging, high-speed multi-processor computing and flexible software. With over 1,000 installation worldwide, the NSX 330 System offers 2D inspection and metrology at high throughput and a broad portfolio of 3D sensors supporting critical advanced packaging applications. These include wafer-level metrology for micro bumps, RDL, kerf, overlay, and through silicon via (TSV) in a single wafer load.

Accommodating wafers from 100mm to 330mm, the system features a versatile objective turret, programmable light tower, and multiple dark field illumination modes. Additional features include resolution flexibility, unique handling solutions, and comprehensive software for recipe sharing and offline analysis. The NSX 330 system, with optional edge and backside inspection via the EB40 module, provides a comprehensive all-surface inspection solution packaging technology challenges.

Applications

- Macro inspection: whole wafer, and film frame

- Gel and waffle pack inspection

- OQA and post saw

- Post Probe and Testing

- Substrate thickness, TTV, and bonded wafer thickness stack thickness (carrier, adhesive, product wafer and total stack)

- Via depth thick and thin RST

- Bow and warp

Featured Markets

Do you have an NSX 330 system question? Let’s talk!

As your partner for innovative solutions, we’re always here for you.

Discover how our cutting-edge semiconductor solutions are engineered to meet your most complex challenges: delivering performance, reliability and innovation where it matters most.

Let’s Talk

"*" indicates required fields