Enhancing CMP Process Control with Intelligent Line Monitoring & Integrated Metrology

As semiconductor manufacturers push the boundaries of performance and functionality—driven by high-performance computing and AI applications—chemical mechanical planarization (CMP) processes increase in intensity complexity.

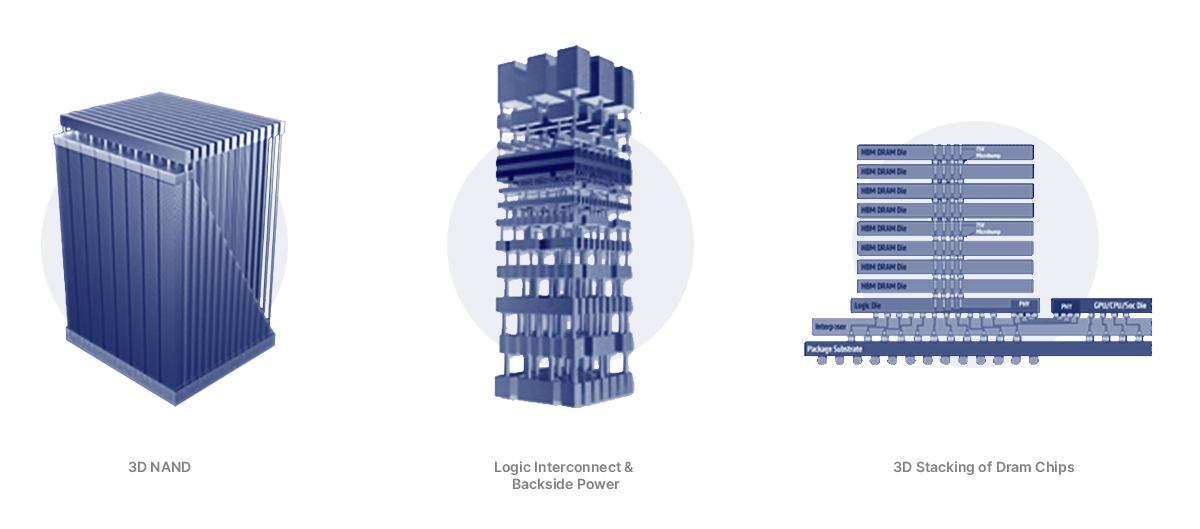

New logic transistor designs, 3D NAND stacking, and DRAM integration introduce more CMP layers and tighter process windows. Traditional metrology approaches struggle to keep pace, especially with the need for high sampling rates, multiple control zones, and improved signal-to-noise ratios.

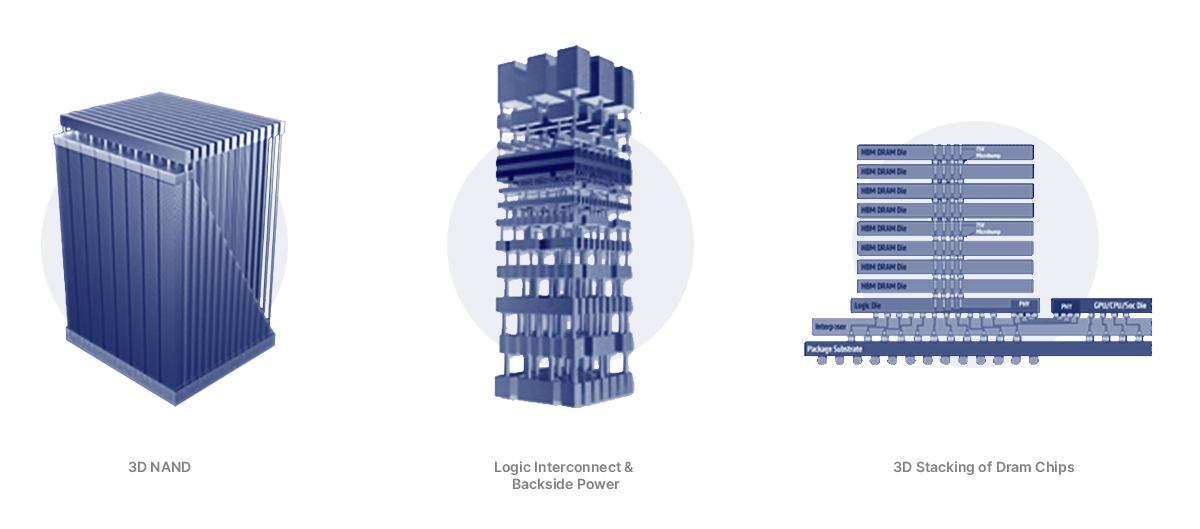

Onto Innovation’s Intelligent Line Monitoring & Control with Integrated Metrology offers a transformative approach to CMP process control.

By leveraging data feedforward from standalone metrology tools to integrated metrology systems, this solution enables real-time, AI-driven process optimization.

At the heart of this solution is the IMPULSE® V system, an advanced integrated metrology platform that connects with standalone tools like the Atlas® system and utilizes Ai Diffract™ modeling software.

This ecosystem enables the creation of hybrid reference models—combining standalone data and limited TEM measurements—to drive high-precision, high-throughput results.

Key Benefits

Accelerated Time to Solution: Feedforward of secondary parameters from standalone tools into IMPULSE system recipes enables faster model convergence and process tuning.

Improved Throughput: Skipping pre-measurements at the integrated metrology stage saves time without compromising accuracy

Reduced Cost and TEM Dependency: Hybrid reference modeling minimizes the need for extensive TEM data, reducing both cost and development time.

Enhanced Process Control: AI-driven analytics and model-based feedback improve excursion detection and process stability, leading to better Cpk performance.

In-Fab Use Case

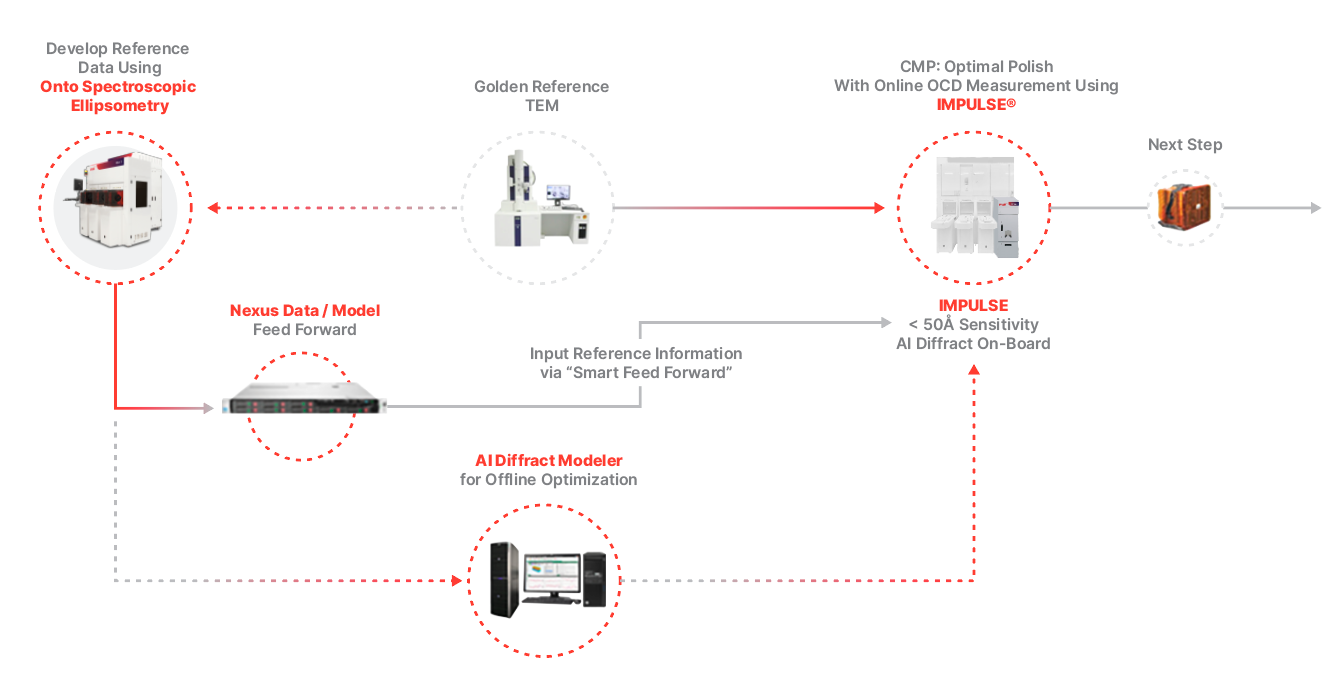

MX PST-POL Full Loop

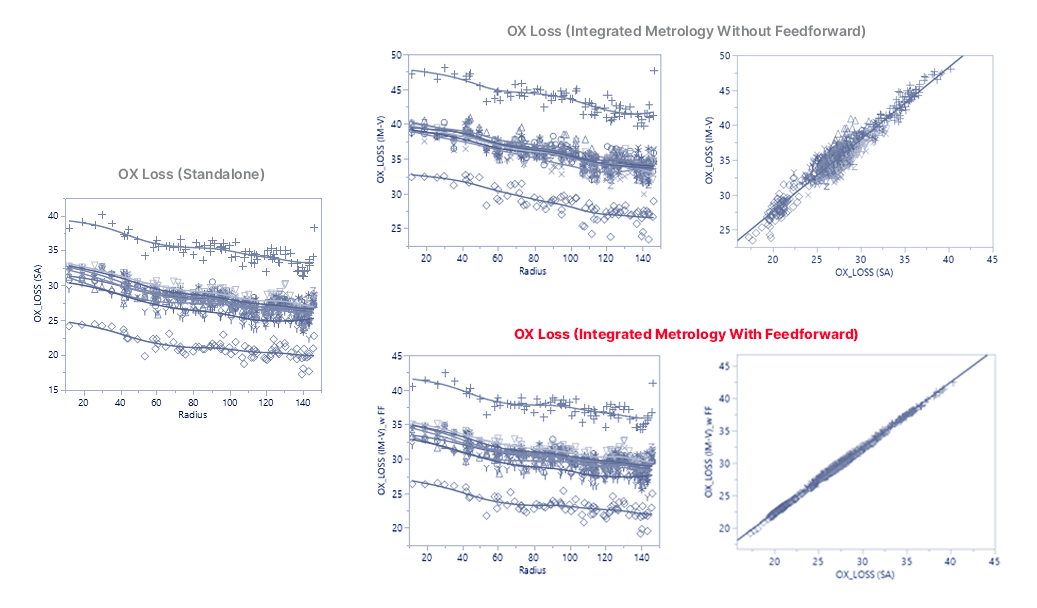

In a production environment, Onto Innovation demonstrated the power of feedforward data integration by correlating oxide loss measurements across standalone and integrated metrology tools. By feeding forward key parameters, the solution eliminated the need for redundant pre-measurements and improved correlation to reference data—delivering both time savings and enhanced process control.

You Have a Challenge? Let’s talk.

We’d love to connect with you.

Looking to learn more about our innovative solutions and capabilities? Our team of experts is ready to assist you. Reach out today and let’s starts a conversation about how we can help you achieve your goals.

Let’s Talk

"*" indicates required fields